Schedule a Call Back

HHV builds directional solidification furnace for PV industry

Industry News

Industry News- Aug 26,23

Related Stories

Zetwerk acquires majority stake in KRYFS to power India’s energy future

This strategic acquisition creates a stronger platform for India’s energy transition with advanced digital manufacturing and transformer expertise.

Read more

HHV Advanced Technologies invests in EON Space Labs for imaging tech growth

HHV Advanced Technologies joins EON Space Labs as investor and partner to scale AI-driven imaging payload manufacturing and launch ultra-lightweight space telescope MIRA in 2025.

Read more

Ammann India Expands ABG Paver Production and Aftermarket in Gujarat

Ammann India rolls out its first ABG Paver and launches a high-tech parts warehouse in Gujarat, boosting local manufacturing, service support, and exports for road construction equipment.

Read moreRelated Products

Biomass and Coal Fired Spreader Stoker Boiler

Sitson India Ltd offers a wide range of biomass and coal

fired spreader stoker boiler

Coil Type Boilers - VRS Series

Maxima Boilers Private Limited offers a wide range of coil type boilers - VRS Series

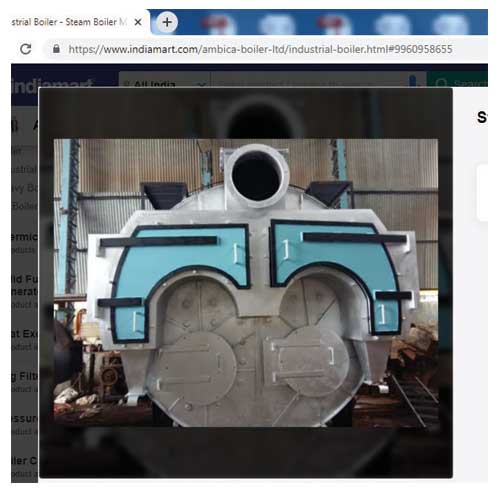

Steam Boiler

Ambica Boiler offers a wide range of steam boiler.