Schedule a Call Back

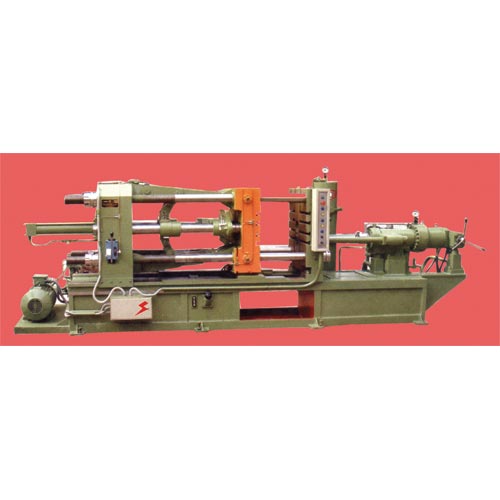

Pressure Die-Casting Machines, Cold Chamber

Pressure Die-Casting Machines, Cold Chamber

Rapid Flow India Pvt Ltd offers horizontal Cold Chamber Pressure Die-Casting Machines, built with best quality materials and components. These are available in four models: 80, 120, 180 and 250 tonnes capacity. The machine can be operated on manual as well as semiautomatic basis, and suited for mass production of die-cast components (such as automobile, electricals, toys, measuring instruments and home appliances) for casting of aluminium, zinc and their alloys. The machine base is extra strong structural construction, which supports the injection system on its extension. Part of the base is attached with oil reservoir to accommodate a good quantity of hydraulic oil and is provided with oil gauge and digital thermometer. Die locking is effected by means of hydraulic and sturdy toggle mechanism exerting an evenly distributed force over the faces of the dies. The die space between the two die mounting plates is adjustable to suit any die thickness as mentioned in the table. The die locking mechanism is four hard chrome plated tie bars running on linear bushes for smooth movement of moveable die, and water cooling arrangement for die plate and fixed platen. Injection plunger is hydraulically operated and powered with high-pressure accumulator to give fast sequence of shots. The provision of lower injection and central injection is provided. A separate ejection cylinder for ejecting the casting from the die cavity has been provided. A shell and tube type condenser is provided to prevent the overheating of oil and mould. It can be cleaned very easily after removing both the side covers. Hydraulic system consists of double vane pump, relief valve flow controls valve, accumulator, unloading valve and solenoid operated direction control valves. All controls are fitted on single manifold to avoid complicated tubing. All electricals consists of standard makes switchgears, relays, contractors, etc., are housed in a central metal cabinet. An operating control box (mounted on the fixed die plate) located at the operating position ensures full safety of operation. An emergency stop switch also provided to ensure instantaneous stopping of all motion in case of need.