Schedule a Call Back

Hot Glass Conveyor Belts

Hot Glass Conveyor Belts

Tuff Temp and Hi-Temp Fabricated Pads

At Tuff Temp Corp. we have a fully equipped fabricating shop, which is capable of producing highly, customized pads (i.e. scoop pads, vacuum pads, etc.), liners, seals, gaskets and expansion joints to meet your unique high temperature needs. Our on site technicians can provide customized form cutting, hole punching, sewing and slitting to meet your unique specifications.

No Charge Samples

Please allow us the opportunity to prove our value to you by providing you with no charge samples of any of our products, which you can then test head to head against your current high temperature materials. All that we need are your material specifications, and we will then gladly forward TUFF TEMP product samples direct to your plant, anywhere in the world. In addition, TUFF TEMP has local Agents and Distributors located throughout the world, ensuring quick and responsive service to your high temperature needs, without language and/or cultural barriers.

For Any High Temperature Handling Application - TUFF TEMP Is The Ideal Product Of Choice

TUFF TEMP’s unique high performance properties make it ideal for a truly diverse wide range of high temperature applications. For example, our TUFF TEMP high temperature resistant conveyor belting is used to convey all of the following types of products:

- Hot Glassware

- Hot Soft and Hard Alloy Aluminum Extrusions and Other Metals

- Hot Cement

- Hot Sand

- Hot Chemicals

- Hot Carbon Black

- Hot Welding Flux

- Hot Wood Paneling

- Hot Washing Machine Lids

The above list is just a small sampling of the types of high temperature conveyance and handling applications where TUFF TEMP is the ideal product of choice. Please feel free to contact one of our highly qualified Sales Engineers to see how our TUFF TEMP conveyor belting can be used for your unique high temperature application.

TUFF TEMP Woven Materials

- Temperature Resistance: Up to 1000°F / 540°C Continuous and Up to 1400°F / 760°C Intermittent

- Thermal Conductivity: 0.04 Btu.in/(h.ft2.°F)

- Abrasion Resistance: Excellent

- Cut Resistance: Good

- Chemical Resistance: Good resistance to acids and alkalis, Excellent solvent resistance, Degraded by strong mineral acids and bases, Excellent resistance to mildew and aging

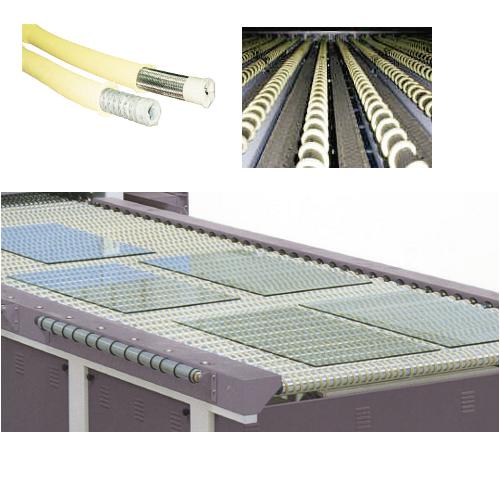

Oven Roller Tapes and Ropes

During the thermal tempering process glass is heated up in the range at temperatures nearing the melting point. Soon thereafter the glass exits the furnace and is rapidly quenched with cool air to strengthen it. As the glass exits the furnace it is conveyed over a series of cold metal rollers. These quench rollers are spirally wrapped with our TUFF TEMP Oven Roller Tape or Rope, which is used as a protective buffer material, preventing the hot glass from picking up any unacceptable thermal checks.

We have been supplying our products to the flat glass market for over twenty years, and today, TUFF TEMP Oven Roller Tapes and Ropes are supplied to almost the world’s entire largest horizontal tempering range manufacturers. Our customers include the leading horizontal tempering range OEM’s in all corners of the world. In addition to supplying the OEM’s, TUFF TEMP CORP. also directly supplies numerous secondary glass tempering companies. Our global customers include many of the world’s largest flat glass manufacturers as well as many small and mid-size companies as well. Whether a multi-billion dollar multinational company, or a small local start-up, all TUFF TEMP customers are treated with the very highest level of customer service.

Quite simply, Tuff Temp has become the world’s leading manufacturer and supplier of Oven Roller Tapes & Ropes because they provide the very longest wear life, unmatched durability, and excellent heat & wear resistance, and are totally non-marking on even the most sensitive glass types. In addition to superior life, TUFF TEMP Oven Roller Tapes and Ropes are highly resistant to deformation, ensuring even and consistent roller heights throughout your quench, even after extended time with running heavier weight glass.

TUFF TEMP and TUFFNIT Tubing

Our TUFF TEMP and TUFFNIT Seamless Tubing are ideal for use as roller covers in hot end production processes such as automotive glass bending, tempering and laminating.

Our TUFFNIT tubing in particular, offers tremendous cost saving opportunities for automotive glass manufacturers. TUFFNIT has been designed to be used as a 1-piece cover on the rollers. Traditionally, within most automotive glass bending and tempering ranges, two roller cover materials have been used on the individual rollers - an under layer covering and an outer layer covering. However, our new TUFFNIT tubing has been engineered to be used as a 1 piece covering, allowing you to eliminate all costs and man-hours associated with purchasing and handling an under layer material. This provides significant cost savings on time and materials.

In addition to the front end purchasing and labour savings, TUFFNIT’s material wear life has been proven to regularly exceed that of the two piece covering, thereby providing significant back end cost savings in production, as run time is extended, and downtime is reduced.

Lastly, all of our TUFF TEMP and TUFFNIT seamless tubing products will adhere well to your rollers, with virtually no slack or creases, providing superior optics on even your most severe bent glass designs.