Schedule a Call Back

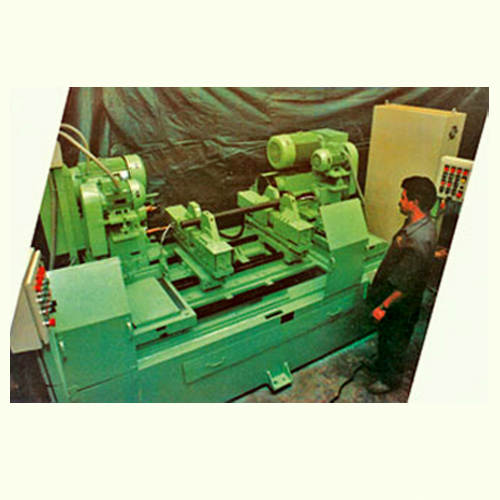

Facing & Centring Machine, Double Ended

Facing & Centring Machine, Double Ended

Double-ended facing and centring machine is ideal for machining components measuring more than 400 mm length. The machine has two separate compound slides for right and left stations. Each compound slide consists of one milling head, one centring unit and centring slide. The compound slides are adjusted as per the length of component. A self-centring vice is provided for component clamping. The component is stationary and cutting slides are moving. Independent drive motors take care of face milling and centre drilling operations. Separate slides are provided for centring operation. An electrical panel working on PLC is used to control machining operations. Specifications: Model C – minimum component length – 400 mm, max length – 600 mm, and max dia – 125 mm. Model D – minimum component length – 600 mm; max length – 1000 mm, and max dia – 125 mm.