Schedule a Call Back

Compressed Air Dryers

Compressed Air Dryers

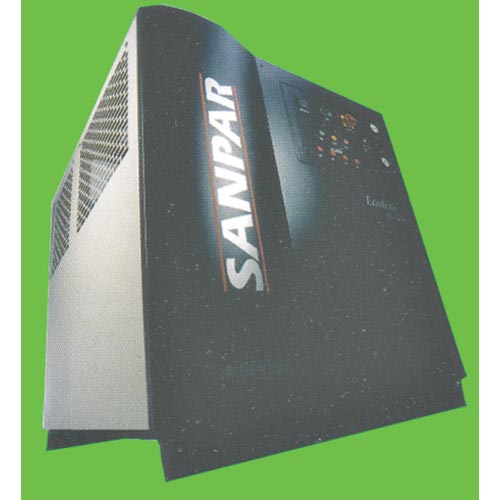

Sanpar Microfilters is a manufacturer of precision engineered, compressed air treatment systems for industrial applications. The product range of the company comprises refrigerated air-dryers, compressed air dryer, micro filters, drains, after coolers, de humidifiers, moisture separators, climate controllers, refrigerated oil coolers, air and water chillers, differential pressure gauges, and differential pressure indicators. The compressed air dyer the company offers employs the latest technology of aluminium plate type heat exchangers. While plate type heat exchangers are compact and light in weight, the Xeros compressed air dryer also employs vacuum brazing used on plate heat exchangers. Put to helium leak test up to 27-bar g, the compressed air dryer has a compressor with high COP that contributes to power benefits. The victaulic couplings provided on the compressed air inlet and outlet connections make for easy maintenance. There is negligible pressure-drop in the refrigeration line. It is therefore possible to utilize complete rated cooling capacity of the compressor. Fitted with Rotolocks at the refrigerant inlet and outlet, the compressed air dryer has been tested with electronic detectors for refrigeration piping leak to ensure that the leak is of the order of 3 g/year. The R232 port with interface software has been provided as an optional feature for remote monitoring. The company also offers Moisture Separators, Refrigerated Air Dryers, Zero Air Loss Automatic Drain, etc.

Product & Technology News

- Latest technology of aluminium plate type heat exchangers

- Plate type heat exchangers are compact and light in weight

- Latest technology of vacuum brazing used on the plate type heat exchangers

- Heat exchangers put to helium leak test up to 27-bar g

- Optimum selection of compressor with high COP contributes to power benefits

- Victualic couplings provided on the compressed air inlet and outlet connections for easy maintenance

- Negligible pressure-drop in the refrigeration line

- Hence utilising complete rated cooling capacity of the compressor

- Heat exchangers easily retrofitted without affecting the refrigeration line – Rotolocks at the refrigerant inlet and outlet

- Refrigeration piping leak tested with electronic detectors ensuring that the leak is of the order of 3 g/year

- RS 232 port with interface software provided as an optional feature for remote monitoring

- Capacity – 50 to 10,000 cfm

- Operating pressure – 3 to 14 bar g.