Schedule a Call Back

CIP System For Automatic Defect Removal System

CIP System For Automatic Defect Removal System

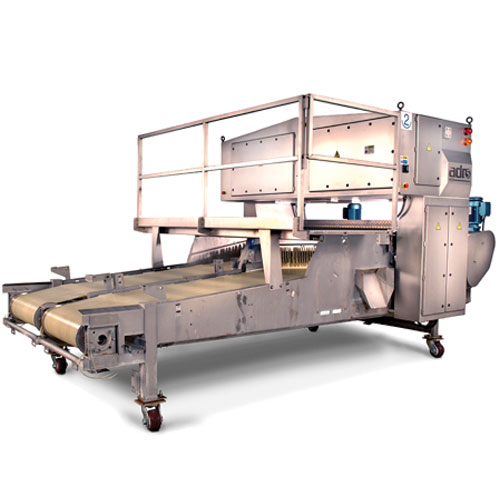

Key Technology has introduced CleanBelt, a new clean-in-place (CIP) system for ADR® 5, the popular automatic defect removal system for potato strips. This automated CIP system reduces sanitation and maintenance labour, minimizes the cost of replacement parts, and helps maintain the optimal performance of the ADR 5 system to accurately match product quality to specifications. The company has made CleanBelt a standard feature on all new ADR 5 systems, and offers it as an in-field upgrade to processors with installed ADR 5 systems. For processors with older ADR systems, Key offers CleanBelt as a standard feature on upgrades to ADR 5 from ADR II, ADR III, and ADR 4c systems. With a combination of passive and active cleaning systems, CleanBelt continuously removes starch from the ADR belt to prevent build-up. The consistency of this routine ensures a uniform inspection background for the ADR cameras over time, which eliminates the need to recalibrate ADR and helps maintain optimal inspection performance without degradation. Just as important, preventing starch build-up reduces the risk of belt mis-tracking, which can cause costly damage to the knives and cutting wheel. CleanBelt eliminates the need to manually remove starch from between belt lanes and reduces the need for the ADR belt to be manually cleaned. It extends the intervals between cutter wheel rebuilds and significantly reduces knife replacements, which saves labour and parts.