Schedule a Call Back

Air Wipes

Air Wipes

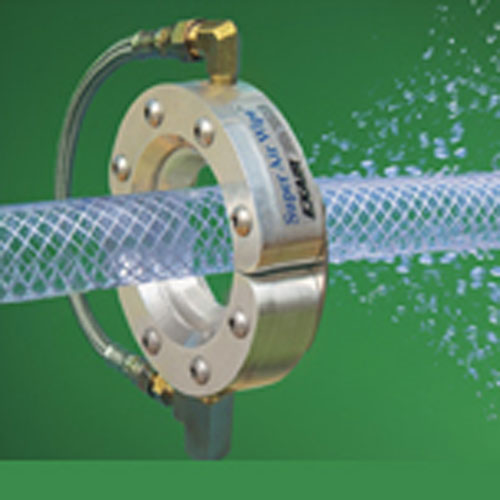

Vivek Engineers a range of Air Wipes sourced from Exair Corporation, USA, as the authorised distributor in India. EXAIR’s Air Wipe produces a “laminar†flow of air along its 360° angle using the “Coanda†effect, which “entrains†a large volume of air from the surrounding area along with the small amount of compressed air. It is easy to mount and the split design provides easy Super Aire Wipe Split Designclamping around the surface of the material, eliminating the need for threading. EXAIR Air wipe reduces both compressed air consumption and noise levels.

It produces an output flow up to 30 times. All Super Air Wipe models include stainless steel screws & shims. For added corrosion & heat resistance braided hose is also included on sizes up to 4†(102mm).For Aluminum models the temperature rating is up to 400°F (204°C) & stainless steel models for temperature up to 800°F(427°C).

Prior to the introduction of the Super Air Wipe, the only way to blowoff, dry, clean and cool cylindrical, round, or extruded surfaces were to use a ring of air nozzles. The high air consumption and noise levels of the nozzles along with inconsistent air velocity often delivered poor results. The Super Air Wipe provides a high volume, high velocity airflow that is uniformly ejected from the 360° of its inner diameter. The airstream attaches itself to the material running through it to effectively wipe, clean or dry surfaces. Velocity can be varied from a “blast†to a “breezeâ€. Air consumption and noise are low.

Advantages:

- Quiet

- Low air consumption

- Uniform airflow across the entire diameter

- No electricity, no moving parts

- Non-contact - no wiper blade

- Lightweight, low profile

- Tapped holes for mounting

- Split design - compact, rugged, easy to install

- Stainless steel hose supplied on sizes up to 4" (102mm)

- Stainless steel hardware resists corrosion

- Aluminum models for temperatures up to 400°F (204°C)

- Stainless steel models for temperatures up to 800°F (427°C)

- Meets OSHA maximum dead end pressure and noise requirements

- Drying after wash, cleaning, plating or coating

- Blow off dust and contaminants

- Cool hot extruded shapes

- Uniformly wipe surfaces

- Dry extruded profiles, rod and medical tubing

- Eliminate solution carry - no cross contamination

- Blow excess water from automotive door gaskets

- Remove excess coatings, water and oil

- Dry tube, hose, wire, fiber optics

- Minimize solution loss due to dragout

- Clean paint gun tips

- Dry screen printed or ink jetted surfaces

- Clean strips and ribbon