Schedule a Call Back

Air Slide Fabric

Air Slide Fabric

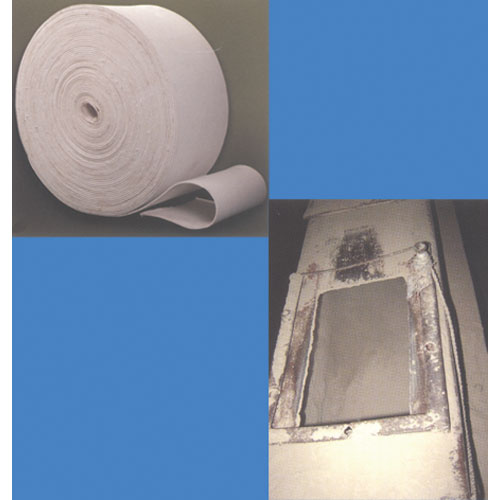

KE Technical Textiles Pvt Ltd offers Air Slide Fabric, a transporter for carrying fine-grain powder in bulk at a very low velocity and also at a high velocity as per need of the individual industry. Carrying of fine dry products like cement is a unique example. It can also carry fly ash, iron powder and gypsum. This transport system consumes less energy and demand low attention for maintenance. It helps dust emission free operation. Weave structure of the fabric is such that only a specific volume of air is allowed to permeate so that the fine powder does not fly in an erratic manner. Powder therefore rests on the conveyer, but because of the gradient by 6°C to 8°C from high to ground level and because of the vibration created by high volume of air flow at wind pressure of 4-5.5 KPa underneath the fabric, the powder gets conveyed to its destination. The company makes air slides with woven selvedge and made to order width. Therefore bolting with the metal body of the conveying chute is very secure. Space required for the assembly is small. This conveying system requires low capital cost and operational cost is less than other systems such as pneumatic conveying system. The company uses high tenacity polyester filament yarn and follow established process a condition weaving to heat treatment and surface treatment. The company, formerly known as KE-Burgmann Fiber India Pvt Ltd, was part of an Indo-Danish joint venture, set up in the year 1991. In 2001 after financial and management restructuring, it became independent of its parent company. It manufactures technical textiles from fibreglass, polyester, nylon and other new generation synthetic yarn for use in lead acid batteries, high temperature, cryogenic, gaseous, corrosive and other hazardous industrial application areas. The company has its own facilities of weaving, processing and coating of fabric with various polymers and resin systems like PTFE, fluoro elastomers, acrylic resins, graphite, silicone phenolic resin, melamine, etc.

- Sabrasion resistance

- Resists blinding

- Rot and mildew resistant

- Unaffected by temperature from 30°C to 140°C

- Thickness 4 mm to 6 mm (higher thickness made on order)

- Input air M3/M2/min 1.6 to 2 (underneath the air slide in the chute)

- Air permeability for 5 mm thickness and 3400g/m² – 0.8 M3/M2/minute at 125 Pa