Schedule a Call Back

Agitated Pan Dryers

Agitated Pan Dryers

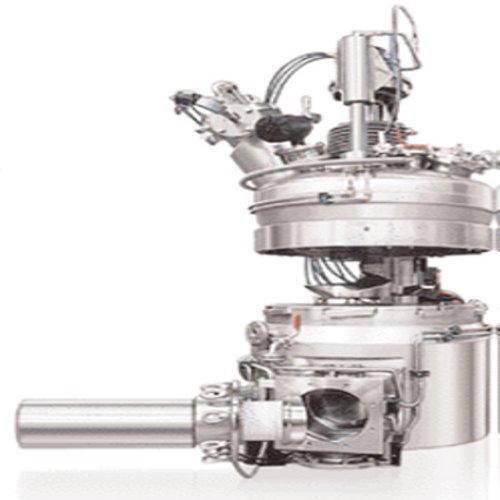

De Dietrich Process Systems is composed of the organizations formerly known as De Dietrich Glass Lining, Rosenmund-Guedu, and QVF Process Systems. Through the integration and synergies of these three companies, De Dietrich Process Systems has become one of the most comprehensive global suppliers of engineered systems, equipment and services for the fine chemical and pharmaceutical industries.Based on the well established and proven Filter/Dryer technology, agitated pan dryers are differentiated by their heated flat bottom plate that effectively enlarges the heating area of the vessel.

Advantages:

- The minimal agitator to wall clearance keeps the wall free from product crust.

- The pan bottom can be easily lowered for fast cleaning (CIP/WIP and SIP) and inspection.

Product & Technology News

It is specifically designed for the batch drying of solids and uses a unique "vortex" mixing action for improved drying performance.

Volumes from 100 to 7500 liters

Available with top or bottom entry-drive technology, the pan dryer comes equipped with a speed-controlled, heated agitator that facilitates short drying times. The pan dryer also features a side discharge valve that enables simple emptying. As with the spherical dryer, the mechanical seal of the pan dryer is also advantageously located outside of the product area. The axial motion of the agitator is sealed by metal bellows, as with the Filter/Dryer