Schedule a Call Back

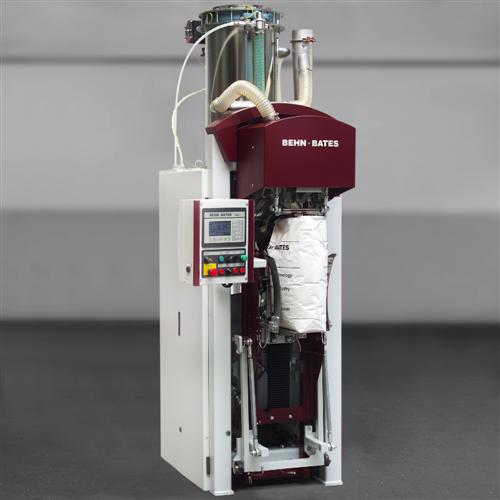

Packing Machine, Pneumatikpacker

Packing Machine, Pneumatikpacker

Haver & Boecker has recently presented a new Packing Machine, the Pneumatikpacker from its subsidiary company Behn + Bates, at POWTECH 2014. The Pneumatikpacker is easy to adapt to customer wishes, thanks to its modular design. Proven in years of industrial use, the Pneumatikpacker remains the optimum system for filling all free-flowing, flour-type, powder-type and gritty products such as starch, flour, cocoa powder, protein, sugar, etc., into valve bags. The Pneumatikpacker uses the air-filling principle. Here the aeration system’s sophisticated concept provides uniform product flow into the bag – and does so at high filling speeds, using minimum air consumption, and with reduced spillage return. The bag is hermetically seal shut using ultrasound directly at the filling spout after filling. The plant operator thus gets a high-performance machine that produces compact and cleanly filled bags, which are easy to handle later on, and a clean packing environment. The Pneumatikpacker is based on the Behn + Bates modular system. It can be adapted rapidly to special customer wishes. Depending on the product and filled weight, speeds of up to 300 bags per hour with a weight of 10-50 kg are possible. Optimum filled bag weight is assured by the modern MEC weigher electronic system. Whether manual or fully automatic, the Behn + Bates Pneumatikpacker optimally handles the foodstuffs industry’s wide variety of requirements.