Schedule a Call Back

PET Bottle Filling Machine

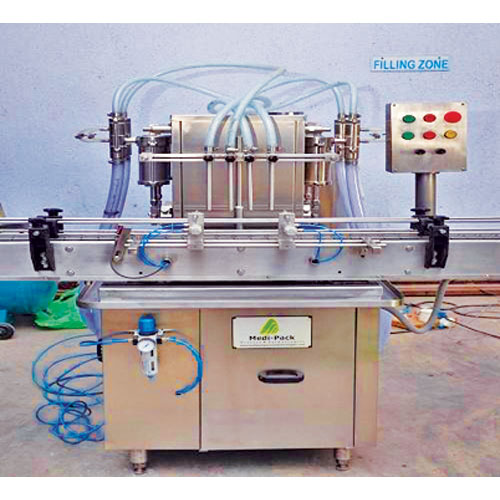

PET Bottle Filling Machine

Medi-Pack Process & Technologies offers pet bottle filling machines.

- These provide for fully automatic operations and feature stainless steel construction finish for durable as well as long lasting performance

- Some of its features include suitable for filling of liquid, paste products and other processed materials; multi filling nozzle support, allows for easy adjustment for different bottles, auto cleaning support, filling speed can be adjusted as per material density and viscosity, choice of adjusting conveyor speed, auto counting system and others

- Industrial bottle filling machine work on volumetric principle with diving nozzles; the unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, of SS slat conveyor, reciprocating nozzle with self-centering devices and SS Syringe

- Conveyor drive consist of A/C motor with synchronised variable A/C frequency drive; ± 1% filling accuracy on single dose; no bottle no filling system

- Rigid vibration free construction for trouble free performance; SS elegantly matt finished body; elegant and easy control panel for total control on operation; minimum change overtime, from one size to another container or fill size

- Self lubricating UHMW-PE guide profile for SS slat chain provides low friction wear surface, smooth and noiseless conveying; error code display on AC frequency drive on control panel; drain tray around machine platform

- Drip tray under the conveyor; pneumatic bottle stopping arrangement; synchronised two nos A/C drive for main motor and conveyor belt; safety guard for conveyor gear box, motor and pneumatic cylinders

- MCB for over load protection, and prevention against short circuit; inbuilt protection against over current, voltage fluctuation, short circuit in AC frequency drive.