Schedule a Call Back

Furnace Profiling

Furnace Profiling

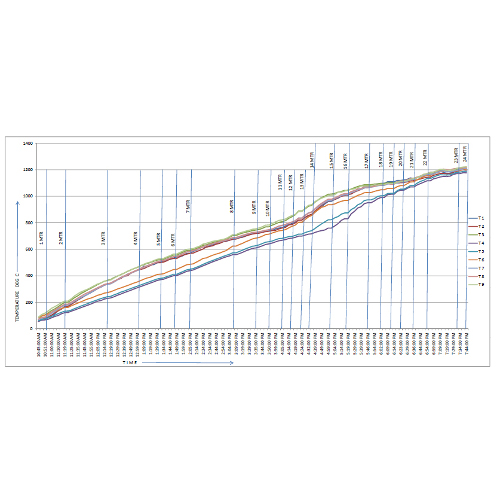

Therm Process Engineering Private Limited offers Furnace Profiling. Most of the time they measure and control furnace temperature without measuring actual temperature of the charge. Furnace profiling system is the term used to describe the process of recording and interpreting the temperature of charge during actual production. Temperature data is measured continuously using thermocouples connected directly to charge ( Billets ) across different cross section and different location. Temperature data collected from the profiling operation provides a graph / profile showing actual temperature the charge experienced during the entire heating process i.e. from charge to discharge. Temperature profiling delivers reliable data to optimize heating process, soaking time & correction in furnace temperature. Advantages: Thermal Analysis of product, Control product quality, mproper heating zone detection, Increase productivity, Improvement in heating cycle and process.