Schedule a Call Back

Drive Solutions For Digital Factories

Drive Solutions For Digital Factories

NORD Drivesystems offers drive solutions for digital factories.

Product & Technology News

- NORD provides both standardised and individually configured solutions for more than 100 industries and regularly sets accents in the field of drive technology. Among other things, NORD has extended its industrial gear unit series. The new 2-stage MAXXDRIVE XT angled industrial gear units were specially designed for applications which require low speed ratios in combination with high powers.

- Output torques range between 15 and 75 kNm with speed ratios of 6.3 to 22.4. Seven sizes are available for powers from 50 to 1,500 kW. As standard, the series is equipped with a heavily ribbed Unicase housing and an integrated axial fan.Â

- Due to the increased surface and the air guide covers, the cooling air flow is optimised and a very high thermal limiting power is achieved. In many cases, addition cooling is not required. Large roller bearings and centre distances increase the load capacity and service life of the components.

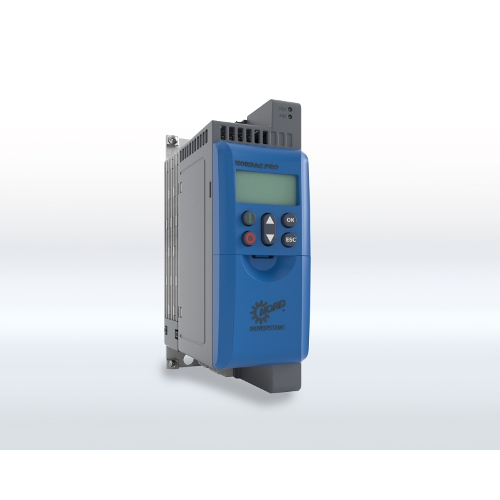

- The new Nordac Pro family control cabinet inverters impress with high levels of functionality, connectivity and modularity. They have a power range from 0.25 to 5.5 kW. Various device versions can be optimally allocated to various application requirements. The functions of the modular series can be extended by plug-in control, safety and option modules.Â

- The compact design in book-size format enables space-saving installation in control cabinets. Parameterisation can be carried out without an external power supply. The new NORDAC PRO has a large number of interfaces, including an integrated industrial ethernet connection, a USB port as well as an SD card slot for storage and transfer of parameter data. As with all NORD frequency inverters, the new device is equipped with a powerful PLC for functions close to the drive.

- With the Nordcon app and the Bluetooth stick Nordac Access BT, the company has created a mobile commissioning and service solution for all NORD drives. The app provides dashboard-based visualisation which is useful for drive monitoring and fault diagnosis. For example, a machine drive can be optimised while in operation with the aid of the oscilloscope function. Parameterisation of drive units is simple and easy due to the integrated help function and rapid access to parameters. In addition, the app provides further practical functions such as a parameter backup and recovery function.

Â