Schedule a Call Back

Plate Fin Type Heat Exchanger

Plate Fin Type Heat Exchanger

Abletech Engineering offers Plate Fin Type Heat Exchanger. The plate bundle of a plate-fin heat exchanger is composed of fin, division plate and seal packing. A fin and a seal packing, which are placed in between two adjacent division plates, form an interlayer called as passage. The interlayers are superposed into a whole by brazing, according to different flowing ways of fluid, forming the bundle of plate (or called core body). Aluminum is applicable to dip brazing with salt solution, so at present the plate-fin heat exchanger is nearly made of the manganese-aluminum alloy, which is corrosion-resistant.The plate-fin heat exchanger usually is fabricated from aluminum, but regardless of the materials of construction, the core is furnace brazed in a controlled atmosphere or high vacuum. Because plate-fin heat exchangers require more precise manufacturing, they are usually more expensive than other designs.

Product & Technology News

- The heat transfer efficiency is high is that the fin can cause the disturbance for the fluid to make the thermal boundary layer rupture and renew continuously. The heat transfer coefficient of forced convective gas is 35 to 350 W/ (m2·?), the overall heat transfer coefficient of forced convective oil is 120 to 1740 W/ (m2·?), while the overall heat transfer coefficient of gas-gas in the shell-and-tube heat exchanger is only 10 to 35 W/ (m2·?).

- Its heat transfer area per unit volume is generally 1500 to 2500 m2/m3, which is 8 to 20 times that of the shell-and-tube heat exchanger. The weight of aluminum plate-fin heat exchanger is one tenth that of the shell-and-tube heat exchanger with the same heat transfer area, but its metal consumption per unit heat transfer area can be dozens of times smaller than the shell-and-tube heat exchanger.

- It can be applicable to the heat transfer of various different fluids such as gas to gas, gas to liquid and liquid to liquid. Depending on the arrangement and combination of various flow passages, the plate-fin heat exchanger can adapt to the heat transfer in different working conditions such as countercurrent, cross flow, multi-flow and multi-pass flow. The plate-fin heat exchanger can be shaped and produced in batch to meet different requirements, so the cost can be reduced and the interchangeability is enlarged.

- The manufacturing process is complicated and the requirements for manufacture are strict.

- It is easy to be blocked and the cleaning and maintenance are difficult. If the inner leakage occurs owing to the corrosion, it is hard to maintain the exchanger.

Products from Abletech Engineering

Gasketed Plate And Frame Heat Exchanger

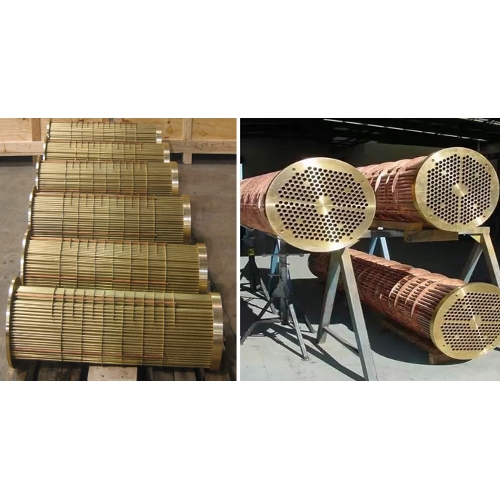

Heat Exchanger Tube Bundles And U Tube Bundles

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads