Schedule a Call Back

We aim to create substantial space for EAPL products globally

Industry News

Industry News- Jul 30,22

Electronic Automation Pvt Ltd (EAPL) started its entry into electronic field with timers almost 4 decades ago. Today, through its collaboration with Switzerland-based Kruger + Co Ltd, EAPL has established itself as a strong player in the manufacturing of standard electronic instruments. In this interview, Shreedhar Kamat, Co-Founder & Chairman of EAPL Group, offers insight into India's electronic manufacturing sector and contribution of EAPL in making the industrial evolution in the country more meaningful and swifter.

How has Electronic Automation Pvt Ltd evolved since its inception in 1985?

EAPL, headquartered in Bangalore, had its humble beginning in 1985. It was the brainchild of Late Shri Madhav Kamat who instituted this venture with espousing support from Mr Christian Kruger of Switzerland. Because of its partnership with Kruger + Co. Ltd, Switzerland, EAPL is part and parcel of a culture associated with Swiss perfection.

EAPL started its entry into electronic field with timers almost 4 decades ago and has created a meaningful space for itself in the Indian electronic industry scenario. We take pride in saying, “We monitor ‘time’ in India”.

EAPL has focused on manufacturing quality products at an affordable cost. The company has always sought to invent devices of high viability matched with sales at low prices; ensuing from critically controlled and standardised quality-oriented manufacturing methods, to and assuring a high caliber product. Additionally, the company is approved by product safety regulators viz. CSA, CE and UL for complying with their regulated safety norms.

The company offers a wide range of electronic products that have proven to be useful across different industries. EAPL has successfully garnered a consumer base in both small and large scale industries based in over 50 cities throughout India, and in a few GCC countries.

EAPL’s product portfolio includes:

EAPL is spread over a vast expanse of 25000 sq ft with an infrastructure capable of manufacturing more than 500,000 units annually. EAPL is one of the earliest establishments in Bangalore to be certified under ISO 9001:2008 by UL (Underwriters Laboratory, USA) and has currently upgraded to ISO 9001:2015, ISO 45001:2018 (Occupational, Health & Safety) & ISO 14001:2015 (Environmental System). The organisation has also adopted the SAP B1 as a part of enterprise resource management and fact-based decision making. At present, the production units are equipped with the latest SMT technology. The Quality Control (QC) department compliments these efforts by executing timely quality checks starting from raw materials to different stages of manufacturing and concluding with the final product (IS5834/IEC guidelines).

The organisation also has its very own tool room and plastic injection molding facility which uses UL graded material and consistently abides by quality and safety protocol. Moreover, the in-house EMI/EMC lab strives to strengthen the validation process in assuring finesse in the quality of products.

What are the USPs of EAPL's products? What do you bring to the table for its customers?

EAPL products are known for its quality, reliability and unique features. They are designed and manufactured by following international standards viz. UL, CSA & IEC, providing confidence of usage to our customers. EAPL products are unique for its compactness, wide operating voltage and ease of operation. It explains our marketing manifesto which is “If a product fails during warranty period, we replace or refund”. This has also indirectly helped us maintain our high quality rating with a failure rate <50 PPM.

How is the electronic instruments market in India? What are the key demand drivers of this market?

The Indian economy is growing quite rapidly among other important markets in the world. Technological advancements have been rapid even in the automation industry which has positively influenced research and production of electronic products. Additionally, the government initiatives such as Make in India and introduction of the GST have proven to be useful in promoting small manufacturing industries. There has been an increase in overall demand for electronic products.

What are the challenges faced by electronic instrument manufacturers in India? What are probable solutions for these challenges?

As an industry, we do have to continuously inform ourselves of new innovations and research that is happening with respect to the kind of products we deal with. Accordingly, we have to ensure that our raw material inventory is updated and that the products we make are useful, effective, and efficient. The process of product design doesn’t halt; there is always room for development. As a manufacturing unit that manages all production in-house, the reality is that monitoring the inflow of raw materials to our facility is quite challenging and requires constant attention so that we are able to meet the product quality and demand. Moreover, recycling and disposal are aspects that the electronics industry needs to look toward more closely.

Are the spiraling raw material prices hurting the industry?

The industry is still coping with the challenges that were posed by the Covid-19 pandemic especially in terms of procuring raw materials, producing products in time, and maintaining sales. The increasing costs of raw materials has invited tough negotiations with vendors, dealers and clients especially since overall costs have increased mainly due to rising costs of electronic components, packaging and transportation.

From your experience, are you seeing the benefits of Make in India initiatives on the ground?

Electronic Automation was honoured with ‘Make In India’ award from India Today group in 2016 for our contribution in the electronics sector. Incidentally, EAPL is one of the promoters of the ESDM facility “Lahari” which is coming up at Mysore. It is an initiative of Make in India. Lahari is the first in kind initiative supported by the Government of India, Government of Karnataka and Indian industry to go operational, with the goal of promoting & evaluating new ideas, new designs and new products, while gaining access to worldwide markets for the emerging electronic industry in India.

There is a strong industry-wide conviction and consensus that Lahari (ESDM) can meet the electronic industry's end-to-end needs like testing, inspection, certification and market access. Mission is to work in the interest of the Indian electronic industry to help it to be compliant, to create new products and new markets. Through its advanced technologies and partnership, Lahari will provide all technological needs of the industry such as testing, certification for all global standards, skill development, product design consultation as end-to end services. The facility will help EAPL to get the products certified for international standards and thereby promoting exports.

What are the emerging trends in the industry?

The growth in the electronic industry in India is driven by the growth in specific segments. The growth of each segment is, in turn, dependent on the dynamics of the existing ecosystem, the number of organised players, the level of imports, and the government’s focus on the respective segment.

The industrial electronics segment has been growing on account of the increasing automation of manufacturing facilities coupled with an increasing focus on harnessing renewable energy.

Could you please brief us about some of EAPL's recently launched products? Any new products in the offing?

EAPL has launched many products recently. Some of them are variants of the existing design and others are with new concepts.

What are growth plans for the future?

With the existing infrastructure, EAPL can double the production and there is a possibility to expand further with the available space, facilities and technology. We are soon planning to introduce IoT (Internet Of Things) features in energy meter, annunciators, etc. We believe that markets are gradually shifting from RS485 mod-bus to WiFi/LORA/GSM connectivity for remote monitoring of parameters. We will also be introducing some specific application based products relating to the electric vehicle (EV) segment. Additionally, Electronic Automation will be stepping into the “Building Automation” sector by promoting combination switching timer with real time operations and time switches with multiple relays operating on real time for industrial sector and street light applications. Power saving is the theme behind these products.

Some more products lined up for designing are simplified version of App-based PLC with ease of program, Extension of IoT to other controller products, electric vehicle charging and control, series of control relays for DG/AC protection in export market, multifunction timer up to 100 hrs, automatic power factor controller, intelligent annunciator in compact size.

Recently, our products were certified for ‘CE’ (Conforming to European standards) by third party evaluator - TUV Germany. EAPL products are being exported indirectly by many of our machine manufacturing customers to different parts of the world. Over the last 3-4 years, EAPL has established a dealership network in the Gulf region and will be further expanding to Europe, Africa & South East Asian countries in the coming years to create a substantial space for EAPL products in the world market.

Related Stories

India takes a leap in energy transition with innovations at Elecrama 2025

With over 1,100 exhibitors and presence of leading international players, Elecrama 2025 provided a vital platform to witness cutting-edge innovations in the energy sector. The event further reinforc..

Read more

CECO Electric: Pioneering energy-saving technologies for Indian manufacturers

The Kolkata-based CECO Electronics, one of the leading players in the industrial electrical and automation space, is exploring new opportunities in solar pump systems and robotic controls for indust..

Read more

Switzerland green lights historic India-EFTA trade agreement

Signed in March, this comprehensive agreement is designed to enhance trade in pharmaceuticals, manufacturing, and emerging technologies, with a projected investment of $100 billion in India over the..

Read moreRelated Products

Geared Electric Motors

Delco Fans Pvt Ltd offers single phase capacitor run and three

phase geared Instrument motors, totally enclosed face/foot mounted.

“Kusam-Keco” Partial Discharge Acoustic Imager - Model - Km-pdai

‘Kusam-Meco’ has introduced a new “Partial Discharge Acoustic Imager Model KM-PDAI.

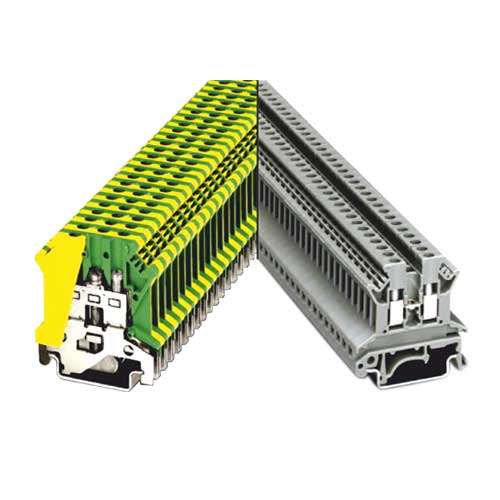

78 Series Din Rail Terminal Blocks

Werner Electric Private Limited offers a wide range of 78 series din rail terminal blocks.