Schedule a Call Back

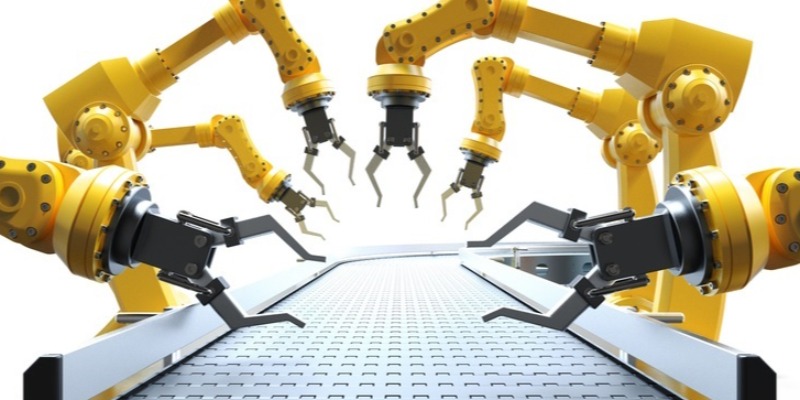

Ten types of robots you’ll find in a manufacturing plant

Technical Articles

Technical Articles- May 18,21

Related Stories

Neolite ZKW Commissions New Automotive Lighting Plant in Pune

Neolite ZKW Lightings Limited has commissioned a new manufacturing and design facility in Pune to strengthen automotive lighting capabilities and support OEM customers across vehicle segments.

Read more

Why Batteries Trail Strategy in Humanoid Robot Development

Battery makers are racing ahead of robot OEMs in positioning humanoids as the next growth frontier. This press release examines developments from both perspectives and considers how deeper cross-ind..

Read more

Is your facility ready to handle the energy demands of full automation?

As warehouses scale AI-driven automation, energy demand is emerging as a critical constraint alongside productivity gains. Strategic power planning is now essential, writes Emily Newton.

Read moreRelated Products

Digimatic Smart Caliper

Veekay Industries offers a wide range of digimatic smart caliper.

Compact Fmc - Motorum 3048tg With Fs2512

Meiban Engineering Technologies Pvt Ltd offers a wide range of Compact FMC - Motorum 3048TG with FS2512.

Digital Colony Counter

Rising Sun Enterprises supplies digital colony counter.