Schedule a Call Back

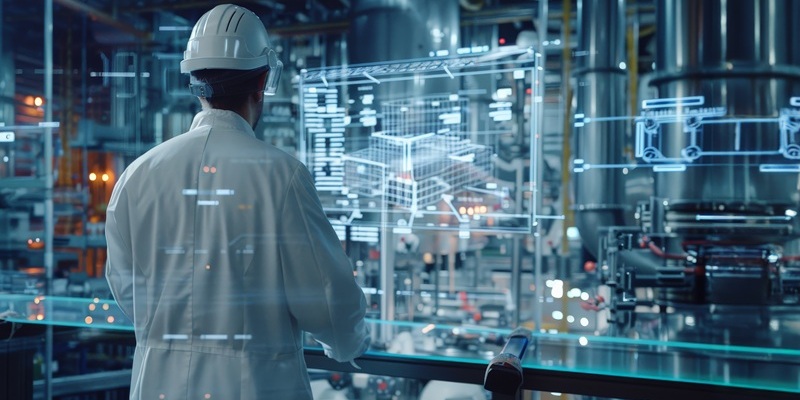

6 Nonnegotiable requirements for your smart factory transformation

Articles

Articles- May 27,25

- Programmable logic controllers (PLCs)

- Industrial-strength Ethernet

- Wireless communications like Wi-Fi and Bluetooth

- Data acquisition systems

- Firewalls

- Endpoint security

- Business continuity planning

- Virtual private networks

- Encryption

- Data minimisation

- Intrusion detection systems

Related Stories

Caliber Interconnects showcases AMRs and robotic handlers at Automation Expo

Caliber’s Autonomous Mobile Robots (AMRs) are AI-driven, customizable automation solutions engineered for industries such as warehouse logistics, manufacturing, e-commerce fulfilment, healthcare, ..

Read more

Beyond fixed automation: The rise of dynamic factory systems

In this article, Emily Newton highlights how dynamic factory systems use AI and automation to boost resilience, efficiency, and flexibility in manufacturing.

Read more

How MNCs are strategising to capture market in India

Today, the Indian MNC scene is changing vastly, with many new ones setting up shop in India. With China becoming less attractive, India is becoming the go to place, writes R Jayaraman and Firoz S Ri..

Read moreRelated Products

Digital Colony Counter

Rising Sun Enterprises supplies digital colony counter.

Robotic Welding SPM

Primo Automation Systems Pvt. Ltd. manufactures, supplies and exports robotic welding SPM.

Heat Exchanger Scale Removal Compound -hesr-300

Hi There!

Now get regular updates from IPF Magazine on WhatsApp!

Click on link below, message us with a simple hi, and SAVE our number

You will have subscribed to our Industrial News on Whatsapp! Enjoy