Schedule a Call Back

"Our core strength is to develop optimised turnkey machining solutions"

Technical Articles

Technical Articles- Jan 09,15

Shorter cycle times, minimal change over time, flexible batch size machining, lower tool and maintenance costs, and greater component quality are the growing demands of Indian auto component industry and global OEMs based in India that increases the pressure on metalworking industry. Here, tailor-made production solutions play an important role in the competitive world. EMAG is a worldwide proven supplier for solutions in the form of single machines or turnkey fully automated production lines. It is a "One Stop Shop" to solve manufacturing constraints and is best known for its Precision and Productivity either in batch or mass production volumes. Andreas Zieger, Managing Director, EMAG India, talks about the company's participation at IMTEX 2015. Excerpts

What are the products you are bringing at IMTEX 2015?

EMAG is known for a wide range of machines with various technologies like Turning, Grinding, Gear Hobbing, Laser Welding, Hardening, Heat Shrink Assembly and Electro Chemical Machining. Loaded by that expertise our core strength and recognition from customer side is to develop optimised turnkey machining solutions for metal parts with high quantity and quality requirements. This technology expertise together with our basic pick up vertical spindle machine concept where we can optimise the loading operation and thus minimise the idle time gives us the advantage to help our customers to achieve best cost per piece. Now the world is turning faster and especially in the automotive sector life cycle of each car model gets shorter and shorter. That's why we developed a new modular standard machine concept, in which we included step by step all our technology know-how. This standard modular machine concept increases the flexibility in the production process. Each machine has a small foot print, can very easy be connected, can be added or shifted in a production line according to demand changes and for maintenance can be simply replaced. At the moment we have a wide range of vertical turning pick up machines for chucked parts and shafts ready to use, also turning and grinding machines or hardening machines. During the exhibition we will show one machine for chucked parts up to 200 mm dia and with other display techniques we will demonstrate the flexibility of such machine concept.

What is the USP?

The USP is the flexibility of such a machine concept. Simple solid EMAG high quality machines, optimised for each operation step, can be combined to complete production lines. These lines can be connected by manual loading, but also in that case with our added basic automation an operator free high end quality is ensured, or in case the output requirement goes up it can be linked by robots, change over units or track motion elements. Together with that flexibility in the machine concept and easy reaction on quantity chances the maintenance of the whole line and thus the running cost will drastically go down. Ideal time in the worst case, caused by mishandling or input quality change can be minimised by simple exchanging a unit. And on the other hand the spare part management or training of the operator or maintenance staff can be reduced. All in all logical advantages, which many of us know from our playtime with the modular plastic blocks out of which we could create all kind of magic.

What are the new trends in machine tools today?

Beside the permanent growing price and quality pressure, which can only be achieved by using optimal machine concepts and technologies the time to react on product changes becomes a more and more critical decision factor. As mentioned the product cycle time decrease, the required quantities vary stronger and thus the part supplier has to be more flexible. On the other side we realise over the last years a change to smaller more compact cars and components, which leads to more detailed high quality components and harder materials. Here new technologies earlier considered as exotic, become more common and gets integrated in the production lines. Here we get more orders for part with laser welding, heat shrink assembly operations or electro chemical machining. Especially the last technology is for some operations very interesting, because it is a tool less operation and reduces the tooling cost to nearly zero especially for very hard material. Last point I want to mention is the increasing interlink of electronic and mechanic, we see more elements integrated in the machines, like safety checks, part quality checks and performance control system of the machine linked over networks which allow a more real time control of the process.

India still has to import over 50% of its machine tool requirements. Why?

This will change, first of all the Indian Machine Builders have already collected long experiences. Technology is pulled in to India fast too, driven by the demand of international companies and Indian export oriented companies. On the other side we see a more optimistic industry focused politics, which will attract more international investment and know how. Also for EMAG we try to use the chances of the good market and the highly educated and international oriented workforce and want to develop our presence to support the Indian market but see also a potential to support all our international operations off as a global player.

What are the problems machine tool manufacturers have to face?

We as high end machine manufacturer still face a more price sensitive environment in the mid-range segment in India, were quality, environmental aspects and long-time considerations play a less significant role. On the other side we see that the especially in the high end range with international sales focus that points gain significance to survive in the international market. And other research shows that arguments like work force, electrical consumption, space will get a higher significance in the near future also in India. Another often mentioned aspect is the education level of the work force, sophisticated machines necessary to get the optimum out of the technology and process, requires educated and skilled labour, these are the key players of an business operation. Only with excellent people who are able to handle excellent tools excellent results can be achieved. But the recognition of the machine operator in the society is still at the low end. Last point here is the understanding of service and maintenance in the daily operation. Even a high end machine needs a routine check and maintenance. We offer that preventive maintenance support and wish that it would get a wider acceptance, to allow a longer trouble free operation, which leads to significant lower life time costs.

What are the expectations from the government?

Like all business oriented organisations we like to find a supporting surrounding, from good infrastructure over low bureaucratic hindrances till to good education structure, which support by practical trained work force. On the other side I hope as a human being, that all elements of the society profit from the positive development in the country and that the environmental focus will be sharpened - topics like air pollution, water shortage, waste management are points which lead to a satisfied living quality.

EMAG India Pvt Ltd, Bangalore. Tel: 080-42544400. Fax: 91-80-42544440. Email: info@india.emag.com

Related Products

Fully Welded Ball Valve

Flowjet Valves Pvt Ltd offers a wide range of fully welded ball valve.

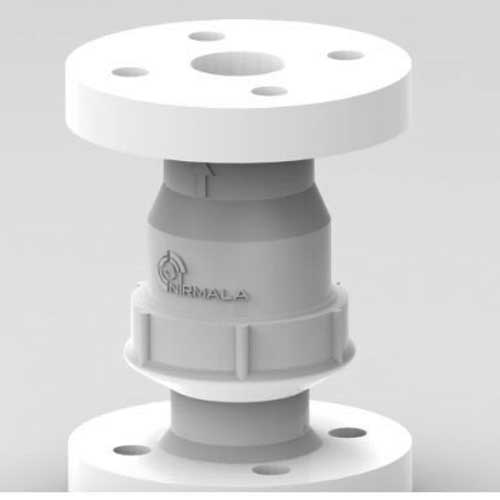

Ball Type Non-return Valves

Nirmala Pumps & Equipments offers a wide range of ball type non-return valves.

Motor Integrated Grinding Spindles

Shenoy Engg Pvt Ltd offers a wide range of motor integrated grinding spindles.