Schedule a Call Back

Moving It Up, Down, Back & Front

Technical Articles

Technical Articles- Dec 24,13

When Col R S Bakshi retired from the army, the first thing on his mind was to invest his years of engineering experience into an entrepreneurial venture. That is how the Pune-based Hindustan + Automation came into being which, in just a decade's time, has been the winner of several awards for innovation and customised projects

A company manufacturing medical components situated in Gurgaon wanted to become more proficient and competitive by automating the assembly of its products through different bowls on an assembly station. The plastic moulded components were in a wide range of sizes and differed both in width and height. It was a problem that called for a unique solution. And that is when they thought of Pune-based Hindustan + Automation Feeders. Both, Col R S Bakshi (retired) and his son Chirag, who spearhead this material handling solutions' company, went to work on this assignment and designed a feeder system that would feed each of the components namely needle, butterfly, stopper, hub, and Teflon thread with a feed rate of 150 parts per minute.

A company manufacturing medical components situated in Gurgaon wanted to become more proficient and competitive by automating the assembly of its products through different bowls on an assembly station. The plastic moulded components were in a wide range of sizes and differed both in width and height. It was a problem that called for a unique solution. And that is when they thought of Pune-based Hindustan + Automation Feeders. Both, Col R S Bakshi (retired) and his son Chirag, who spearhead this material handling solutions' company, went to work on this assignment and designed a feeder system that would feed each of the components namely needle, butterfly, stopper, hub, and Teflon thread with a feed rate of 150 parts per minute.

Elaborating about how it was done, Chirag says, "We tooled a custom 400 mm diameter vibratory feeder bowl. The feeder bowl design consisted of two orientation tracks that converge into a single in-line discharge. We also provided, as part of our turnkey feed system, a 1 cubic foot supply hopper, mounting plate with legs, isolation feet, and a sound enclosure. The important features that made it a success comprised bolt-on, quick-change orientation devices and selectors providing rapid part changeover; lift-off or hinged sound enclosure doors and panels providing unobstructed access to feeder bowl tooling; capped-off return pan to reduce part cross-contamination; and easy access quick-dump feature, allowing for rapid part removal and changeover."

Elaborating about how it was done, Chirag says, "We tooled a custom 400 mm diameter vibratory feeder bowl. The feeder bowl design consisted of two orientation tracks that converge into a single in-line discharge. We also provided, as part of our turnkey feed system, a 1 cubic foot supply hopper, mounting plate with legs, isolation feet, and a sound enclosure. The important features that made it a success comprised bolt-on, quick-change orientation devices and selectors providing rapid part changeover; lift-off or hinged sound enclosure doors and panels providing unobstructed access to feeder bowl tooling; capped-off return pan to reduce part cross-contamination; and easy access quick-dump feature, allowing for rapid part removal and changeover."

For Hindustan + Automation that recently displayed its technologies at the MahaTech exhibition held in Pune, there are many such case studies, the collective successes having led to it being honoured with the Udyog Ratna Award as also the Rajiv Gandhi Excellency Award. Established in 1997 after Col Bakshi retired from the army, the company has made quick progress over the past decade and uses German technology that has helped it become a market leader in feeding processes and customised automation. "We are perhaps the only ISO 9001: 2008 certified company in this segment," Chirag states, adding, "We have been helping all major vertical markets to move, assemble, pack, count and weigh their products. Our custom engineering capabilities include complete part orientation and delivery systems."

For Hindustan + Automation that recently displayed its technologies at the MahaTech exhibition held in Pune, there are many such case studies, the collective successes having led to it being honoured with the Udyog Ratna Award as also the Rajiv Gandhi Excellency Award. Established in 1997 after Col Bakshi retired from the army, the company has made quick progress over the past decade and uses German technology that has helped it become a market leader in feeding processes and customised automation. "We are perhaps the only ISO 9001: 2008 certified company in this segment," Chirag states, adding, "We have been helping all major vertical markets to move, assemble, pack, count and weigh their products. Our custom engineering capabilities include complete part orientation and delivery systems."

Citing another case study to illustrate how the company is known for providing customised solutions, Chirag cites a project that involved replacing existing equipment for a fasteners manufacturing company in Chennai. In this application, a Hindustan+Automation feed system was designed to replace an existing feeder that was worn out. This system now feeds bolts and lock nut with a feed rate of 140 pieces per minute. The special single hopper has two independent discharges feeding in opposite directions keeping both feeder bowls at optimum operating levels. The two 90-degrees down angle tracks were designed to fit directly into the existing bolt press assembly unit.

The company has also worked on critical projects, as for example a feeding system at the nuclear plant of the Bhabha Atomic Research Centre (BARC) at Tarapore. "This project clearly brought to the surface two of our primary strengths - market-leading expertise in vibratory feeding systems and a strong ability to feed a broad range of parts - including the very small ones. Unfortunately, one of our competitors had built the original system, and after multiple attempts had given up - leaving the customer without a solution and rendering the entire system useless. Leveraging our expertise, we re-designed and re-built the entire assembly system, refined and tuned the track, and developed and built a new escapement mechanism. Given the extraordinary small size of the part and its associated features, innovative designs, high precision tolerances, and craftsmanship were required. BARC was very pleased with the resulting system's performance," Chirag says.

The company has also worked on critical projects, as for example a feeding system at the nuclear plant of the Bhabha Atomic Research Centre (BARC) at Tarapore. "This project clearly brought to the surface two of our primary strengths - market-leading expertise in vibratory feeding systems and a strong ability to feed a broad range of parts - including the very small ones. Unfortunately, one of our competitors had built the original system, and after multiple attempts had given up - leaving the customer without a solution and rendering the entire system useless. Leveraging our expertise, we re-designed and re-built the entire assembly system, refined and tuned the track, and developed and built a new escapement mechanism. Given the extraordinary small size of the part and its associated features, innovative designs, high precision tolerances, and craftsmanship were required. BARC was very pleased with the resulting system's performance," Chirag says.

Over the years, apart from such designing and installing such special purpose machines, the company has also evolved as a provider of a vast selection of equipment designed to address the objectives of a safer workplace along with increased productivity. Airport ground equipment and accessories, warehouse material handling equipments, drum lifters and trolleys, lifting equipments and accessories, wire rope pullers, jib crane systems, work station trolleys and carts, specialised assembly work tables, dock levelers, etc. are just some of the other products that make its huge portfolio. "Our feeders can help align and feed anything from general nuts and bolts to specific industrial metal parts like entangled springs, high-precision metallic parts, etc. Our feeders are also important contributors to the clean environments required in the manufacture of medications in pill or tablet form, as well as for medical equipment such as syringes," Chirag states.

Over the years, apart from such designing and installing such special purpose machines, the company has also evolved as a provider of a vast selection of equipment designed to address the objectives of a safer workplace along with increased productivity. Airport ground equipment and accessories, warehouse material handling equipments, drum lifters and trolleys, lifting equipments and accessories, wire rope pullers, jib crane systems, work station trolleys and carts, specialised assembly work tables, dock levelers, etc. are just some of the other products that make its huge portfolio. "Our feeders can help align and feed anything from general nuts and bolts to specific industrial metal parts like entangled springs, high-precision metallic parts, etc. Our feeders are also important contributors to the clean environments required in the manufacture of medications in pill or tablet form, as well as for medical equipment such as syringes," Chirag states.

Having progressed from a company with just four workers, Hindustan + Automation now employs 40 skilled people in its plant at Thergaon and on its expansion menu is to set up more sales and service outlets across India apart from the existing ones at Chennai and Jalandhar as also foray into exports. "We are awaiting our export license. Meanwhile, inquiries have been coming from countries like Malaysia and Dubai," informs Col Bakshi. On the product front, Hindustan + Automation would now like to also focus on elevators. "We already have the cap sorting elevator that can handle flat caps up to 110 mm and with the capacity of feeding up to 1,000 caps per minute and we also offer the bucket belt/chain elevators that are suitable for conveying material vertically as in sectors like construction, mining, power stations, etc. Given the future potential though, we will beef up on this product range too," he concludes.

Having progressed from a company with just four workers, Hindustan + Automation now employs 40 skilled people in its plant at Thergaon and on its expansion menu is to set up more sales and service outlets across India apart from the existing ones at Chennai and Jalandhar as also foray into exports. "We are awaiting our export license. Meanwhile, inquiries have been coming from countries like Malaysia and Dubai," informs Col Bakshi. On the product front, Hindustan + Automation would now like to also focus on elevators. "We already have the cap sorting elevator that can handle flat caps up to 110 mm and with the capacity of feeding up to 1,000 caps per minute and we also offer the bucket belt/chain elevators that are suitable for conveying material vertically as in sectors like construction, mining, power stations, etc. Given the future potential though, we will beef up on this product range too," he concludes.

Contact Details:

Hindustan + Automation, S. No 26, Barne Industrial Estate, Opp. Pudumjee Paper Mill, Thergaon, Pune - 411030. Tel.: 020-27277296. Website: www.hindustanautomation.com

Related Products

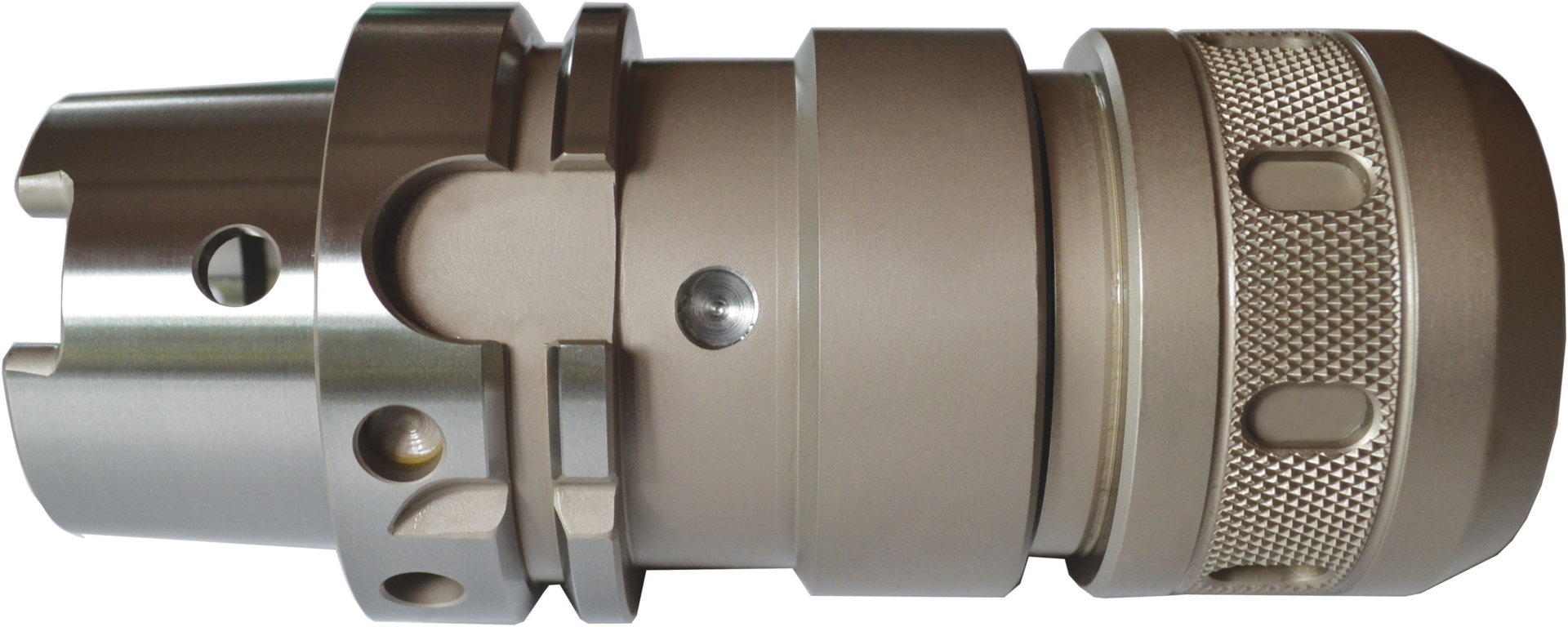

Hi-power Milling Chucks

Bilz Tool

offers a wide range of hi-power milling chucks.

Spur Gears

Shubham Gears is engaged in offering a comprehensive variety of spur gears.

Commutator Motors

J D Automation provides a range of commutator motors, which are also

known as permanent magnet DC motors.