Schedule a Call Back

Hydraulic Equipment for Hi-Tech Projects

Technical Articles

Technical Articles- Feb 02,16

How Oscar Equipments caters to various requirements of hydraulic/pneumatic cylinders and equipment for critical application.

SMEs are the backbone of the economy of a country, it is rightly said. Even in advanced economies like the US or Europe, SMEs account for a lion’s share of production and exports. In the Indian context, SMEs are often at a disadvantage when it comes to policies and patronage, but technologically, there are players in the sector that are second to none.

If SMEs are the backbone of the economy, hydraulics is the backbone of the mechanical engineering industry. Hydraulic equipment – all types of cylinders, actuators, power packs and related accessories – are important components of machines and automation in industries. This is the story of an SME enterprise that has excelled in specialised hydraulic equipment.

Oscar Equipments Pvt Ltd, an ISO 9001: 2008 certified company is a specialised manufacturer of hydraulic and pneumatic cylinders, rotary and linear actuators, electro-mechanical actuators and hydraulically operated equipment for various industrial and strategic applications. Established in the year 1985, the company incorporates latest technological features that offer solutions for increasingly critical requirements based on customised and strategic applications of fluid power. The company is closely associated with original equipment manufacturers of Construction and Earthmoving machinery and associated with Defence Research & Development Organisation (DRDO) as a developmental agency from concept stage to product realisation. “There exists large scope for export of strategic military equipment which can be done effectively through large public sector defence units or recognised private sector companies engaged in production of military equipment with due permission of the MoD (Ministry of Defence),” says V P Jain, Managing Director of the company.

Oscar’s backbone lies in its team of highly professional engineers with vast experience in design, development and manufacturing of hydraulic and pneumatic cylinders and equipment. With its highly dedicated workforce, the company caters to the needs of various steel plants, mines, railways, nuclear power plant and other heavy industries, earthmoving and construction equipment manufacturers besides special hi-tech projects of defence establishments, DRDO units and other strategic applications. “The key to such capabilities is our ability to combine the state-of-the-art features as per customers’ specifications along with most effective solutions,” says Jain. “This expertise is derived from decades of experience available with our team in design and development of various hydraulic products and allied special type equipment for fluid power applications,” he adds. The company is also exporting these products through recognised steel mills/EPC units in India for new steel mills applications and replacement needs.

The company is equipped with complete manufacturing facilities including ‘dust free’ assembly shop apart from automatic honing machines, CNC turning centres, grinding machines, special type welding machines, high pressure and low pressure testing facilities along with complete engineering, research and development facilities and well experienced team for after-sales service.

Quality is the hallmark of Oscar and quality assurance is the top most priority. With the aid of modern equipments the company maintains rigid quality control system at every stage of production. It is an ideal partner for catering to various requirements of hydraulic/pneumatic cylinders and hydraulic operated equipment for any application, any type and any standard. The product range includes: single stage/multi stage hydraulic cylinders, tie rod type standard/customised hydraulic cylinders, hydraulic rotary actuators, electro-mechanical actuators and hydraulic power packs.

The company also undertakes development of special cylinders and products. A few examples:

*For steel plants and heavy industrial applications – automatic gauge control (AGC) hydraulic capsule cylinders capsule cylinders having bore dia 1016 mm (40 inches) for plate mill application

*Automatic gauge control (AGC) hydraulic capsule cylinders capsule cylinders having bore dia 700 mm (28 inches) for cold rolling mill application

*Ladle lifting and tilting hydraulic cylinder having bore dia 500 mm bore with ceramic coated plunger for continuous casting shop

*Ladle lifting and tilting hydraulic cylinder having bore dia 600 mm bore for continuous casting shop

*Hydraulic cylinders for ladle lifting stand for continuous casting shop having bore dia up to 450 mm

*Development of special cylinders and products for steel plants and heavy industrial applications

*Lift and turn hydraulic cylinders for continuous casting shops having roll force cylinders for screw down mechanism of cold rolling mill having bore dia up to 480 mm

*Telescoping hoist hydraulic cylinder having bore dia 480/420/360 mm with total stroke length 8100 mm for steel melting shop application

*Development of special cylinders and products for steel plants and heavy industrial applications, and

*Mud gun hydraulic cylinders for blast furnace applications.

Prestigious Projects

Oscar has executed a number of prestigious projects for strategic applications. A few examples include:

*Sarvatra Bridging System – Fabrication and supply of 3-stage pier leg assemblies including fabrication of base plate in RDG-40 aluminium alloy with synergy pulse MIG welding process for bridging system – Project Sarvatra

*Hydraulic System Launching Mechanism – Fabrication, integration, testing and supply of hydraulic system mounted on the wheeled vehicle Tatra and launching mechanism for 15-mtr span bridging system – Project Sarvatra

*Manufacturing of Pilotless Target Aircraft (PTA) launcher including complete hydraulic system and controls – Project Lakshya

*Manufacturing of Jet Deflector Carrier Equipment and installation of the same on Tatra chassis along with 30 MT crane along with complete hydraulic system

*Pick & Place PLC Type Manipulator – for shell forging unit for ministry of defence unit

*Electro-Mechanical Actuators for Multi-Barrel Rocket Launcher – Project Pinaka; and for Surface to Air Missile Launcher – Project Aakash, and

*Electro-Mechanical Actuators for Cruise Missile Launcher – Project Prahar.

A recent feather in the Oscar cap is manufacturing of a massive 13.5 tonne, 950 mm bore hydraulic cylinder for a coal crusher. This was an order bagged through a global tendering process, which effectively demonstrates the engineering prowess of the company.

Oscar Equipments Pvt Ltd, West Bengal. Tel: 033-24531059/1938. Fax: 91-33-24978494. Email: marketing@oscarequipments.com, oepl1985@gmail.com,

Related Stories

Vardhman Special Steels announces greenfield steel plant and releases Q4 results

Vardhman Special Steels Limited is one of India’s leading producers of special steels and a pioneer in green steel manufacturing.

Read more

Cabinet approves 100 MW expansion of Goaltore solar plant

The plant currently generates 112.5 MW.

Read more

Cheap Chinese bearings are a major concern for India: Rajesh Premchandran

While the Chinese products may be attractive due to price, some of them fall short on performance, leading to frequent failures and increased total cost of ownership for customers, remarks Rajesh Pr..

Read moreRelated Products

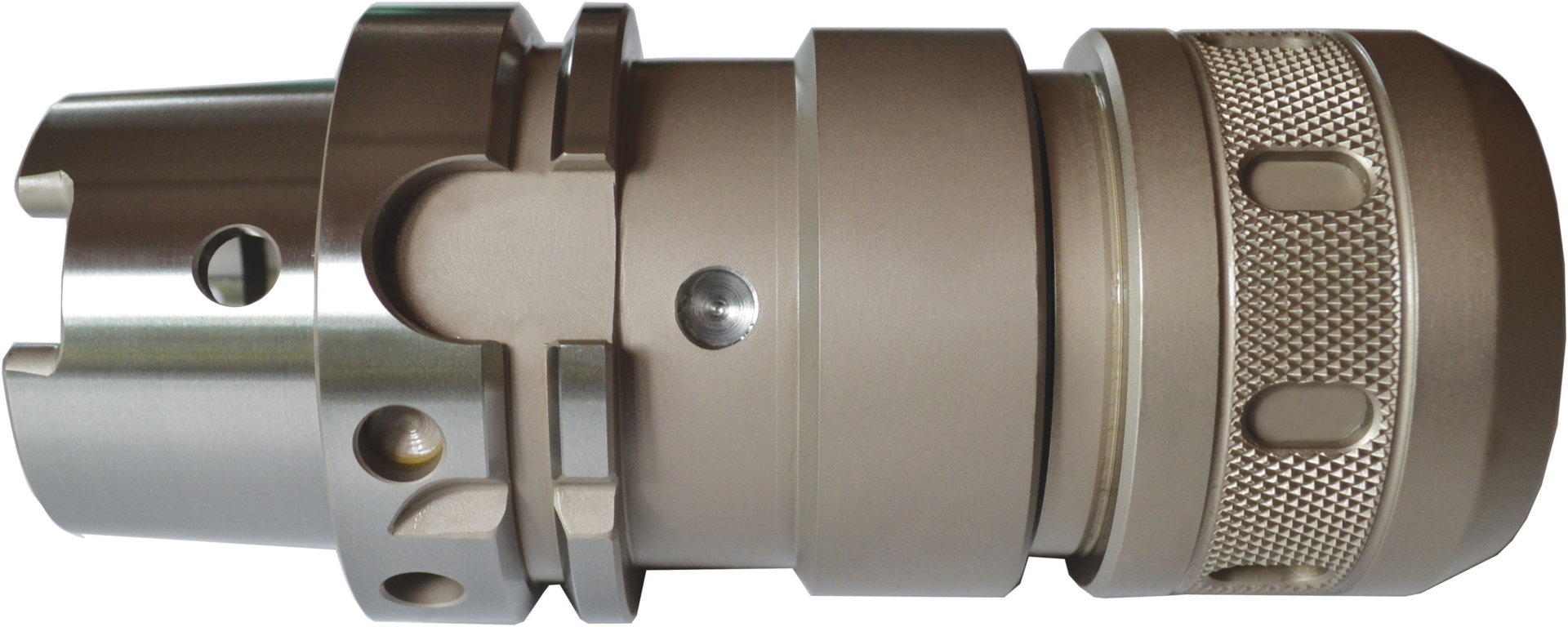

Hi-power Milling Chucks

Bilz Tool

offers a wide range of hi-power milling chucks.

Spur Gears

Shubham Gears is engaged in offering a comprehensive variety of spur gears.

Commutator Motors

J D Automation provides a range of commutator motors, which are also

known as permanent magnet DC motors.