Schedule a Call Back

Cheap Chinese bearings are a major concern for India: Rajesh Premchandran

Interviews

Interviews- Apr 26,25

How do NBC

Bearings and its products drive growth in the sector?

At NBC Bearings,

our focus has always been on innovation, quality, and customer-centric

solutions. We play a pivotal role in driving sectoral growth by offering

technologically advanced and application-specific bearing solutions across

automotive, railways, aerospace and industrial segments. Our ability to cater

to a wide range of industries allows us to respond to evolving needs across

different sectors.

In the automotive

domain, we are at the forefront of enabling new-age mobility—supporting

electric vehicles, ICE, and hybrid powertrains with specialised bearing

designs. Our leadership in the 2W/3W and passenger car markets, along with

growing penetration in CVs, has positioned us as a preferred partner for OEMs.

In railways, our

solutions extend beyond core bearings. We are now offering products for

adjacent systems such as suspension tubes and axle boxes, supporting the

modernisation of rail infrastructure.

Additionally, our commitment to ‘Make in India’ has helped us reduce dependence on imports, align with global quality benchmarks, and enhance domestic supply reliability. Through these efforts, we are not only fuelling sectoral growth but also contributing to India’s ambition of becoming a global manufacturing hub.

What are the

primary drivers fuelling growth in the bearings industry?

Several macro and

microeconomic factors are currently fuelling growth in the bearings industry.

Firstly,

infrastructure expansion is a key driver. Major investments in highways,

railways, ports, and mining are translating into higher demand for construction

and heavy equipment bearings.

Secondly, the

mobility sector is undergoing a transformative shift. Electrification of

vehicles, the adoption of lightweight components, and new drivetrain

technologies are generating demand for newer, application-specific bearing

solutions.

Third, policy

push under ‘Make in India’ and the China +1 strategy is encouraging OEMs and

Tier 1 suppliers to localise their supply chains. This has opened up large

opportunities for domestic bearing manufacturers like NBC, both in India and

abroad.

Finally, increased focus on energy efficiency and sustainability is prompting industries to look for high-performance, low-friction, long-life bearings. Our innovations in materials, coatings, and tribological systems are well aligned to these needs.

How do

remanufactured bearings contribute to sustainability and cost-effectiveness?

Remanufacturing

is a key element in our sustainability strategy. Currently, we offer

remanufactured bearings for the railway sector, where it has been well-accepted

due to high lifecycle costs and the criticality of operations. Remanufacturing

helps extend bearing life while significantly reducing waste and energy

consumption.

The environmental

benefits are clear—remanufactured bearings reduce the need for raw materials,

energy used in production, and carbon emissions. From a customer’s perspective,

they offer a highly cost-effective solution without compromising performance

when done under strict quality controls.

We see immense potential to expand this initiative to other industries, particularly in high-load and slow-speed applications in construction, mining, and industrial sectors. We are in the process of developing a scalable remanufacturing framework that aligns with OEM requirements and sustainability goals of our customers.

How are cheap

Chinese imports and global policies affecting the Indian bearings market, and

what measures are being taken to overcome these challenges?

The influx of

low-cost, low-quality bearings—mostly from China—has been a longstanding

concern in the Indian market. While these products may be attractive due to

price, some of them fall short on performance, leading to frequent failures and

increased total cost of ownership for customers.

The Government of

India has taken proactive steps to address this through the introduction of the

Quality Control Order (QCO), which is being rolled out gradually. This has been

a major step forward in levelling the playing field and promoting the use of

quality products.

From NBC’s side,

we are also focusing on educating customers on total cost of ownership, the

performance advantages of our solutions, and the safety and sustainability

risks associated with inferior imports. We are also expanding our digital

platforms like NBC Connect to authenticate genuine products and protect

customers from counterfeits.

Additionally, global trade policies and supply chain disruptions have made customers rethink their sourcing strategies. This has presented a significant opportunity for Indian manufacturers to become preferred local partners.

What are the most

significant opportunities in automotive and non-automotive sectors?

In automotive,

the biggest opportunity lies in the electrification of mobility. Bearings for

EV motors, e-axles, and wheel hubs require new specifications in terms of

speed, thermal resistance, and insulation. We are well-positioned here with

dedicated R&D and application engineering focused on EV solutions.

Hydrogen ICE and

fuel cell-powered mobility present the next wave of innovation. NBC is already

developing bearings suited for these environments, including

corrosion-resistant and high-temperature variants.

In the

aftermarket, we see immense potential in expanding our offerings beyond

bearings. We’ve entered the lubricants and tools segment and are leveraging

platforms like NBC Connect for customer engagement.

On the non-automotive front, the industrial sector is gaining importance. We’ve identified segments like power, construction and mining, metal processing, and paper as high-potential zones. We are offering customised bearing solutions for these sectors along with digital tools for condition monitoring and predictive maintenance.

How do you

envision the future of the bearings industry?

The bearings

industry is poised for rapid transformation. Going forward, the industry will

be shaped by five key themes:

Electrification

and new mobility – Bearings will have to adapt to higher speeds,

lower torque, and stricter insulation demands.

Digitalisation –

Condition monitoring, sensor integration, and remote diagnostics will become

integral to industrial applications.

Sustainability –

There will be a shift towards green steel, remanufacturing, and eco-friendly

lubricants. Energy-efficient bearings will become the norm.

Localisation –

Supply chain disruptions will drive OEMs to work with nearby, reliable, and

innovation-focused partners.

Customisation at scale – As

industries diversify, off-the-shelf bearings will reduce, and customers will

demand co-developed, application-specific products.

At NBC, we have already begun investing in each of these areas—whether it's through product innovation, process digitisation, or strategic alliances across geographies.

What are your

future plans in India?

India continues

to be a high-priority market for us, both as a consumer base and as a

manufacturing hub. Our plans can be summarised across three key pillars:

Capacity expansion –

With growing demand from rail, 2W/3W, industrial and export markets, we are

expanding our production capabilities. The new plant in Bagru and automation

upgrades across facilities are part of this roadmap.

Innovation and new

product development – We are expanding our engineering teams

and strengthening R&D in areas such as sensor-integrated bearings,

hydrogen-compatible materials, and advanced sealing systems.

Segment growth

and diversification – We are actively building our presence

in non-automotive sectors. We’ve created segment-specific go-to-market teams

and plan to partner with channel players to penetrate industrial markets more

deeply.

We are also

investing in people and digital transformation. From employee development

programs to digital tools for our dealers and customers, our goal is to create

a connected and agile enterprise ready to lead the next era of growth.

Related Stories

Bearings are Spinning India Forward: Sanskriti Ramachandran

Bearings may be small, but they play a critical role in keeping India’s industries running smoothly. With rising demand from sectors like automotive, infrastructure, and energy, the bearings marke..

Read more

Cheap Chinese bearings are a major concern for India: Rajesh Premchandran

While the Chinese products may be attractive due to price, some of them fall short on performance, leading to frequent failures and increased total cost of ownership for customers, remarks Rajesh Pr..

Read more

Igus bearings powers robot to move 600kg shelves

Solid lubricants incorporated into the material ensure low-friction dry operation. As a result, the bearings are maintenance-free and cost-effective.

Read moreRelated Products

Spur Helical Gear

J S Engineering Works offers an assortment of spur helical gear with primarily rolling tooth contact.

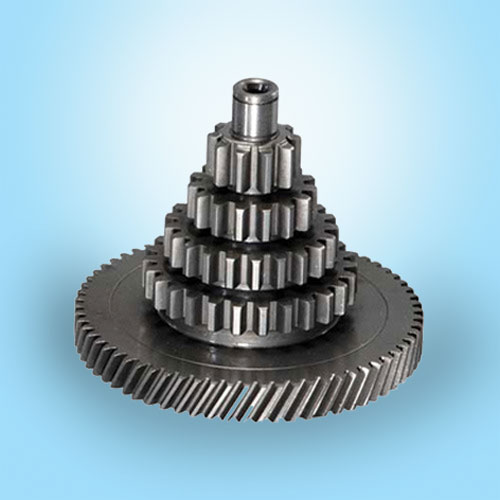

Cluster Gears

Trishla

Gear Industries is engaged in manufacture and supply of a wide range of cluster

gears.

Ground Spiral Bevel Gear

Bevel Gears (India) Pvt Ltd offers a wide range of ground spiral bevel gear.