Schedule a Call Back

Henkel India: Investing in MRO & NVH capabilities

Technical Articles

Technical Articles- Nov 30,-1

Henkel is expanding capabilities of its Innovation Centre at Pune with two new laboratories – MRO Application Development Centre and Acoustic Engineering Centre.

When Henkel inaugurated its Innovation Centre at Pune in 2013, the company had stated that this would contribute significantly towards its Strategy 2016. The family owned but professionally managed company operates globally with direct presence in 120 countries and three business units – Laundry & Home Care, Beauty Care and Adhesive Technologies – of which the two former are Commercial Businesses while the latter is Industrial, where it is a world leader. With global revenue close to USD 20 bn, of which up to 50%, i.e., 9 bn accounted for by the Industrial Business, the company has performed as projected in its Strategy 2016.

Recently, Henkel held a Media Roundtable at Mumbai where the topic for discussion was the company’s adhesive business globally and in India. Central to the Henkel India strategy of course the Innovation Centre at Pune, which is the largest in the emerging markets, which today accounts for 45% of the company’s total revenue. Henkel is now expanding capabilities of this Innovation Centre with two new laboratories – MRO Application Development Centre and Acoustic Engineering Centre – dedicated to the critical areas of maintenance, repair and overhaul (MRO) and noise, vibration, and harshness (NVH), respectively.

These laboratories will facilitate development of products that can meet the unique needs of customers to save costs, reduce downtime and improve performance; test products in simulated conditions in-house before they are used in actual conditions; and train customers on product selection, application, and best practices.

During the interaction, Jerry Perkins, Global Head of General Industry Adhesives, Henkel Group said, “At Henkel, we partner with our customers across diverse industry segments to help them achieve business success. We offer end-to-end solutions to our customers right from developing and selecting right solutions, testing and validation to on-the-line implementation. We are committed to further deepen our partnership with our customers in India, Middle East and Africa with the new investments in the Innovation Centre at Pune.”

Equipment used in industrial facilities – machinery, engines, pumps, pipes, etc., and surfaces of all kinds – have to be able to withstand harsh conditions and heavy-duty use. Henkel works hand-in-hand with customers from heavy industries to meet these new challenges, providing a one-stop shop for tailored services. The new MRO Application Development Centre at Pune is fully equipped to develop and offer Loctite® Polymer Composite solutions to rebuild, repair and protect industrial equipment, prolonging their lifespan. With extremely hard reinforcement fillers, Loctite Polymer Composite products have excellent wear resistance and superior adhesion. They are designed for specific service conditions to protect and extend the service life of a wide range of plant and equipment. The advantage of using these products is that they act as a sacrificial and renewable working surface, protecting the structural integrity of the original substrate. The Centre has full capability to apply and test the performance of these innovative solutions in typical industrial operating environments.

Lightweighting is a key thrust, especially in automobiles and transport segment in general. Cars are becoming lighter thanks to use of engineering plastics and composite materials; with fasteners in several cases replaced by adhesives where possible, or lighter plastic substitutes – shedding weight is an important goal. This helps in improving fuel economy as well as safety. Henkel’s work with railway coach manufacturers has resulted not only in reducing noise and vibrations but also reducing the weight of each coach up to 300 kg! Similarly in household appliances like washing machines where noise and vibration is a key concern, the company has demonstrated dramatic improvement in performance by use of its innovative technologies. To this end, Henkel has its engineers working with the customers’ R&D teams on new product development right from the drawing board stage.

The Acoustic Engineering Centre provides comprehensive testing of Henkel’s individual and combined parts and pumpable acoustic solutions, offering customers performance and economical expertise in acoustics, along with detailed analytical results of their findings to offer optimum NVH solutions. In addition to panel vibration and sound propagation of a typical body structure, the facility conducts evaluations for vibration damping or stiffening body panels using materials loss factor. Additionally, sound transmission loss and absorption is used to measure and optimise body-in-white or component treatments. At the Centre, Henkel’s trained team of engineers analyse acoustic material properties of structures and panels to determine their effectiveness in automotive, off-road equipment and appliance applications. With the latest equipment and software, to perform measurements and analysis, Henkel is able to offer full capabilities including Computer Aided Engineering (CAE), Finite Element Analysis (FEA) and lab testing.

“Henkel anticipates, responds to and meets customers’ expectations, building partnerships with them to achieve success,” said Pradhyumna Ingle, Business Director, General Industry, Henkel India. “The MRO and Acoustic Centres will go a long way in working with our customers to work on finding complete solutions to their design, efficiency and reliability challenges,” he added.

Henkel is upbeat on India, very optimistic given the potential in terms of infrastructure development and automotive growth. It has 9 manufacturing sites and a Product Development Centre, and is currently building the world’s largest, state-of-the-art adhesives manufacturing plant in the country. With the adhesives segment recording a 3% growth annually, the company expects to grow 2-4% across its three business units per annum.

Globally, Henkel works on its Vision 2050, whereby it aspires to become 5 times more efficient by the year 2050, and to that end, it has adopted ‘Factor 3’, where the idea is to triple the value it creates while keeping the footprint at the same level; or alternately reduce the ecological footprint to one third of today’s level, achieving the ‘Factor 3’ improvement in efficiency by delivering the same value.

With an unmatched portfolio of over 3000 products across 60 technology categories catering to over 800 industry segments, and a ‘total solutions’ approach – the company serves over 2 million B2B customers – such ambitions are not unrealistic. Above all, Henkel also has a unique business model that drives demand creation through a unique approach of customer education and training, which in turn generates demand in terms of new applications discovered as a result of process improvement!

Related Stories

Texmaco Rail Secures Rs 1.32 billion BLSS Wagon Order from TTRL

Texmaco Rail & Engineering Limited has secured an order worth Rs 1.32 billion, excluding taxes, from Touax Texmaco Railcar Leasing Private Limited (TTRL) for the supply of a rake comprising BLSS and..

Read more

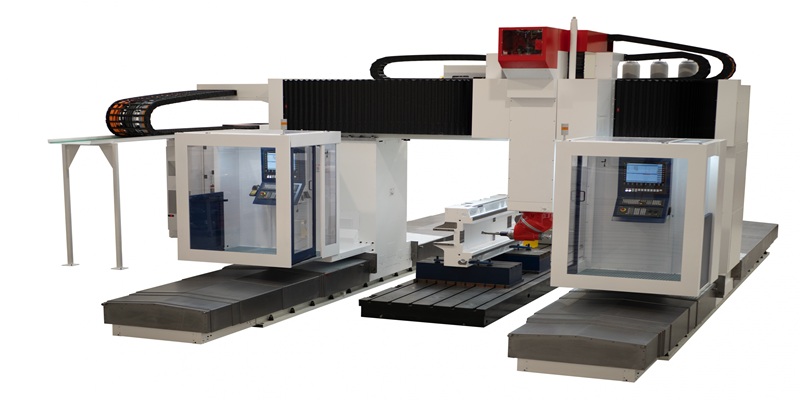

Powermill G3 HPC3 Showcases Italian Excellence in Large-scale Precision Milling

Combining robustness, precision and Industry 4.0 connectivity, the Powermill G3 HPC3 exemplifies Italian manufacturing excellence for large-scale, high-accuracy machining.

Read more

Toyota Kirloskar Motor and NISE partner to advance India’s green hydrogen goals

The partnership represents a critical convergence of industry, research, and national policy to accelerate India’s transition toward a clean, secure, and hydrogen-based energy ecosystem.

Read moreRelated Products

Three Pole, Numerical, Non-directional 3 O/c or 2 O/c+1 E/f Relay With Inst. Highset

JVS Electronics Pvt Ltd offers a wide range of three pole, numerical, non-directional 3 O/C Or 2 O/C+1 E/F relay with inst. Highset JNC 066/JNC 066P.

Ph Fwd/ Rev Motor Protection Ssrs

Insys Electrical & Controls offers a wide range of PH FWD/ REV motor protection SSRs.

Multifunction Meter With Event Counter

Electronic Automation Pvt Ltd offers a wide range of multifunction meter with event counter - model-E2M 4.0A