Schedule a Call Back

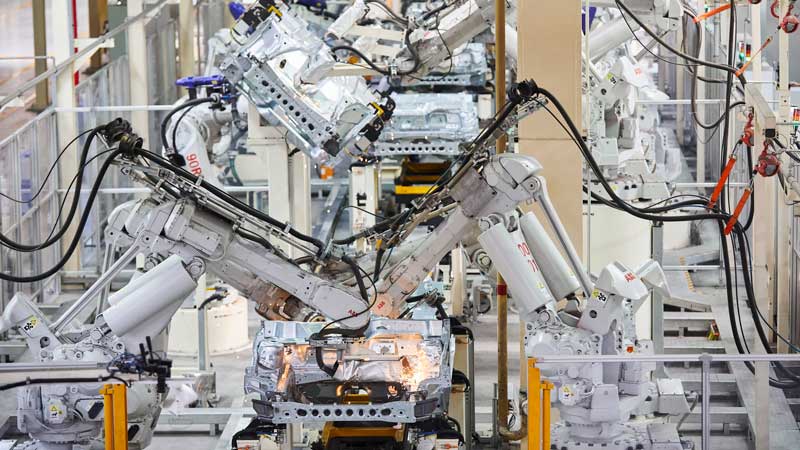

Riding the Industry 4.0 wave

Technical Articles

Technical Articles- Aug 01,18

Related Stories

AI on the edge will transform the shop floor: Sameer Gandhi

In this interview with Rakesh Rao, Sameer Gandhi, MD, OMRON Automation Pvt Ltd, elaborates on trends and opportunities as the manufacturing sector opts for data-led decision-making, quality and safe..

Read more

Can AI be the game changer for Indian manufacturers?

While manpower issues and quality are driving adoption of industrial automation, cost and lack of knowledge are causing hindrances. Artificial intelligence (AI) can be the game changer, writes Rakes..

Read more

Quest to increase efficiency in manufacturing driving robots demand in India

With 59 per cent increase in robot installation in 2023, India has emerged as one of the strongest growing markets. Many believes robots will be central to achieving India’s ambition of becoming a..

Read moreRelated Products

Ultra-slim Humidity/temperature Indicator With Large 4” Display

Countronics offers a wide range of ultra-slim humidity/temperature indicator with large 4” display – Model 7100-4W.

Read more

Integrated Electric Gripper S Series

IBK Engineers Pvt Ltd offers a wide range of integrated electric gripper S series.

Geared Electric Motors

Delco Fans Pvt Ltd offers single phase capacitor run and three

phase geared Instrument motors, totally enclosed face/foot mounted.