Schedule a Call Back

Quest to increase efficiency in manufacturing driving robots demand in India

Articles

Articles- Nov 30,24

Table: World's Top 10

Markets for Robots

|

|

Countries |

Annual installations (in '000 units)

of industrial robots in largest markets in 2023 |

Growth over 2022 (in %) |

|

1 |

China |

276.3 |

-5 |

|

2 |

Japan |

46.1 |

-9 |

|

3 |

USA |

37.6 |

-5 |

|

4 |

South Korea |

31.4 |

-1 |

|

5 |

Germany |

28.4 |

7 |

|

6 |

Italy |

10.4 |

-9 |

|

7 |

India |

8.5 |

59 |

|

8 |

France |

6.4 |

-13 |

|

9 |

Mexico |

5.8 |

-3 |

|

10 |

Spain |

5.1 |

31 |

Source: International Federation of Robotics (IFR)

By region, 70 per cent of all newly deployed robots 2023 were installed in Asia, 17 per cent in Europe and 10 per cent in the Americas. China is setting the pace, accounting for nearly 40 per cent of the world’s total operating stock of industrial robots, followed by Japan.By region, 70 per cent of all newly deployed robots 2023 were installed in Asia, 17 per cent in Europe and 10 per cent in the Americas. China is setting the pace, accounting for nearly 40 per cent of the world’s total operating stock of industrial robots, followed by Japan.

The robot market in India - which includes industrial robots, collaborative robots (cobots), and mobile robots - is also experiencing significant growth. One of the most important factors driving the demand is the rising industrial automation need to enhance productivity and efficiency in varied manufacturing sectors. Sameer Gandhi, Managing Director, OMRON Automation, India, says, "Supportive government policies to boost domestic manufacturing are also contributing indirectly by fueling the rise in adoption of industrial automation and smart manufacturing. Innovations in artificial intelligence (AI) and machine learning (ML) are also opening new vistas making progressive manufacturers explore more capabilities and versatility presented by robots.”

The robot market in India - which includes industrial robots, collaborative robots (cobots), and mobile robots - is also experiencing significant growth. One of the most important factors driving the demand is the rising industrial automation need to enhance productivity and efficiency in varied manufacturing sectors. Sameer Gandhi, Managing Director, OMRON Automation, India, says, "Supportive government policies to boost domestic manufacturing are also contributing indirectly by fueling the rise in adoption of industrial automation and smart manufacturing. Innovations in artificial intelligence (AI) and machine learning (ML) are also opening new vistas making progressive manufacturers explore more capabilities and versatility presented by robots.”

Thriving domestic market

As per IFR report, sales of industrial robots in India reached a new record of 8,510 units installed in 2023 - an increase of 59 per cent compared 5,353 units in 2022. Takayuki Ito states, “India is one of the fastest-growing economies among emerging markets in Asia. The number of industrial robots in operation has nearly doubled since 2018, reaching 44,958 units in 2023, reflecting an average annual growth rate of 14 per cent over the past five years.”

Subrata Karmakar, President, Robotics & Discrete Automation Division, ABB India, adds, “This upward trend has propelled India to the seventh position globally in annual robot installations, showcasing its strong potential for automation as the demand is expected to grow further into 2024 and 2025. Besides global factors such as flexibility, quick changeovers, and ‘batch size one’ production, the adoption of automation by medium and small-sized companies (SMEs), efficiency and quality improvements, economic uncertainty, skilled labor shortages, and sustainability are key drivers. Additionally, India-specific factors like the Production Linked Incentive (PLI) schemes promoting local manufacturing and the shift of value chains, especially in the electronics industry, into India are major driving forces for the adoption of robotics automation in Indian industries.”

As industries look for innovative automation solutions to enhance efficiency, the robotics market in India is experiencing significant growth, particularly with the rise of collaborative robots (cobots) and mobile robots. Bir Singh, Co-Founder & Chief Business Officer, Addverb Technologies, believes robots are central to achieving India’s ambition of becoming a global manufacturing hub, as they enhance efficiency, consistency, and scalability in operations. "By adopting robotics, India can streamline its manufacturing processes, improve quality standards, and reduce costs. With the rapid adoption of automation technologies like cobots and mobile robots, industries can increase their production capacity and meet global demand while maintaining competitiveness," he explains.

Companies are aiming to become cost optimised, more competitive compared to other countries who are vying for a large pie of the global manufacturing market, increase exports of equipment or components (especially in the growing markets like electronics), produce best quality finished products, etc. Automation and robotics can really help them achieve all these goals.

Manish Walia, Head - Industrial Automation, Delta Electronics India, adds, "With global companies now looking at India as an alternative to our Eastern neighbour, it is important for India to have a competitive edge over other countries who are also vying for the same China-Plus-One pie. While the government is giving lots of incentives for companies, the real game changer for India will be increasing productivity of manufacturing units. For improving efficiency, apart from the skilled workforce, robots have to play an important role. They help in high-precision manufacturing, enhancing productivity and quality, eliminating errors and becoming cost competitive, among others."

Over the last 6-8 years, the country has witnessed rapid adoption of automation and digitization. "The pandemic has been one of the key drivers for the adoption of the Industry 4.0 concept. Additionally, with the advent of new-age technologies such as 5G, IoT, AI to name a few, we can expect more investment towards digitization to meet the growing industrial demands of India," explains Vishal Dahiya, Associate Director, Panasonic Smart Factory Solutions India.

Companies view robotics not just as tools but as enablers of transformation— driving efficiency, precision, and scalability. Dahiya elaborates, "Robots ensure consistent quality, reduce human error, and enable high-volume production at competitive costs, making 'Made in India' synonymous with excellence. Moreover, robotics aligns very well with Industry 4.0 initiatives by integrating seamlessly with IoT, AI, and data analytics, empowering manufacturers to adapt to market demands in real time. They also play a crucial role in addressing workforce challenges, such as upskilling and ergonomics, allowing human talent to focus on innovation and strategic tasks."

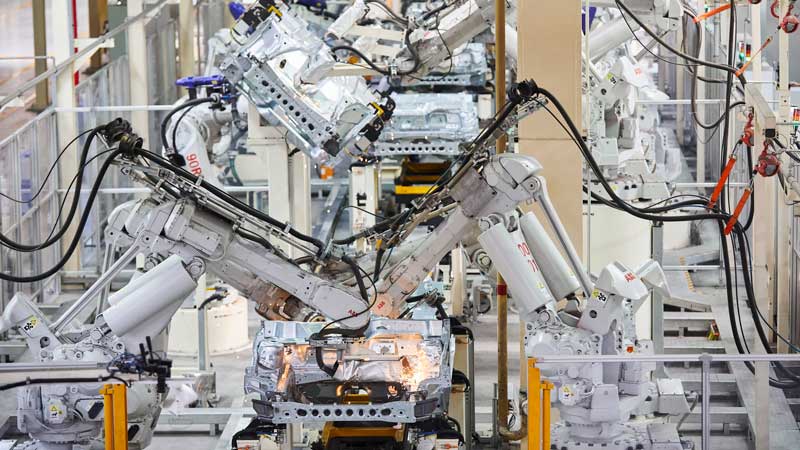

Autos the key drivers

Automakers have been at the vanguard of efforts to automate more assembly line processes to trim labor costs and bolster worker safety. Gandhi adds, "Amongst the industries, the automotive sector is a major adopter of industrial robots for tasks such as welding, painting, and assembly. High demand for precision and efficiency in electronics manufacturing is also driving the use of robots. Mobile robots are gradually transforming logistics and warehousing by automating material handling and inventory management."

Globally, the automotive industry is second only to electronics manufacturers in deploying robots in factories, with about one-quarter of new installations in 2022, according to the International Federation of Robotics.

Figure 1: No of robots installed worldwide in

2023 (by Industry)

|

Industries |

Robots installed in 2023 (in '000

units) |

Share in % |

|

Automotive |

135 |

25 |

|

Electrical & Electronics |

126 |

23 |

|

Metal & machinery |

77 |

14 |

|

Plastic & chemical products |

22 |

4 |

|

Food |

15 |

3 |

|

All Others |

75 |

14 |

|

Unspecified |

91 |

17 |

|

Total |

541 |

|

Source: International Federation of Robotics (IFR)

In India, installations in the automotive industry surged by 139 per cent in 2023, reaching 3,551 units, driven by both car manufacturers and parts suppliers. This sector now holds a 42 per cent market share. The rubber and plastics industry leads the general industry in India, with 408 units installed, marking a 17 per cent increase. Meanwhile, installations in the metal industry remained stable at 329 units in 2023. "India’s fast-paced adoption positions it as a key emerging player in Asia. With sustained investment and growing interest across sectors, especially in automotive, India is poised to solidify its presence in the global robotics arena, marking it as a country to watch in the coming years," opines Karmakar.

For example, Mahindra & Mahindra's (M&M) Automotive and Farm Equipment Business leverages robotics in its automotive manufacturing, enabling faster production cycles and improved quality control. In June 2024, M&M selected ABB's PixelPaint technology for its new electric vehicle paint facility. The deployment of the technology also includes 42 robots from the IRB 5500 family making M&M the first OEM in India to use PixelPaint technology for the painting of contrasting roofs and pillars. PixelPaint consists of a paint head with more than 1,000 tiny, individually controlled nozzles, mounted on an ABB robot. By deploying PixelPaint-equipped robots in dedicated cells, Mahindra's paint shop will be able to apply finishes such as contrasting roof and pillar treatments on its new line of EVs in a completely automated process.

Similarly, Tata Motors is reportedly investigating the use of AI-driven robots for welding tasks, with the goal of enhancing efficiency and ensuring greater safety for workers on the assembly line.

A shift to electric vehicles (EVs) is providing new opportunities for carmakers to boost productivity with the latest robotic technology. EVs require fewer parts and can be assembled more easily with prefabricated modules.

Beyond auto

Robotics is expanding into new industries and sectors that have not traditionally been served by automation. “AI-powered robots are making significant contributions in dynamic environments like healthcare and life sciences, while also driving productivity improvements and safety enhancements in the construction industry,” says Karmakar.

Figure 2: Robot installation in India in 2023

|

Industries |

No. of Robots Installed in 2023 |

Share in % |

|

Auto |

3,551 |

42 |

|

Rubber and plastics |

408 |

5 |

|

Metal |

329 |

4 |

|

Others |

4222 |

49 |

|

Total |

8,510 |

|

Source:

International Federation of Robotics (IFR)

While the automotive industry is the biggest adopter of robots in the country, one could see good traction from other sectors like electronics, paints, pharmaceuticals, etc as well for robots in the near future. "Historically, we never ever looked at robots being used beyond the automotive industry. This is changing with more acceptances from other industry verticals. Post Covid, as could be seen from the IFR report, there has been wider acceptance of robots in India from not just large corporations, but also from small & medium enterprises," observes Walia.

Though the initial cost of robots are high, they are cost-effective in terms of the total cost of ownership (TCO) as they can play a big role in reducing the cost of the entire manufacturing process. Walia elaborates, "High initial cost of installation is a hurdle for wider adoption of robots as customers in India typically look at the initial cost of acquiring robots or any kind of new systems. So, it is important to educate the customers about the benefits of robots in terms of TCO, advantage of precision manufacturing, improvement in quality of finished goods/products, etc."

India is the third most sought-after manufacturing destination in the world and has the potential to export goods worth $ 1 trillion by 2030. "Aligned with this momentum, the smart factories market in India is experiencing significant growth, driven by the adoption of advanced technologies like the Internet of Things (IoT), AI, and automation. Industries such as automotive, electronics, pharmaceuticals, and food and beverages are increasingly adopting smart factory solutions (that include robots and cobots) to enhance productivity and competitiveness. The rollout of 5G technology is enhancing communication and coordination within smart factories, enabling more seamless operations. Additionally, initiatives such as the National Manufacturing Policy and Production Linked Incentive schemes, are also working as a catalyst to demand and growth," states Dahiya.

Khushboo Doshi adds, “Automation has become essential in today’s manufacturing landscape, both in the products we offer, such as plastic extrusion machines, and within our own manufacturing processes. Incorporating automated features in our machines simplifies operations for our customers as well as ensures we stay at the forefront of technological advancements. Looking ahead, we plan to integrate robotics and other advanced technologies into our upcoming manufacturing facility.”

AI: Transforming robotics

AI is enhancing the intelligence of industrial robots, enabling manufacturing plants to operate more efficiently, quickly, and with greater precision. Automakers globally are experimenting with this cutting-edge technology. According to Karmakar, AI is transforming robotics by driving new levels of autonomy, expanding applications into diverse sectors, and making robots more accessible to a broader range of users. The advancements in AI are enabling robots to perform complex tasks such as gripping, picking, and placing with greater precision, as well as navigating through dynamic environments.

AI’s predictive capabilities further support operational efficiency by enabling predictive maintenance, which is crucial in industries like automotive manufacturing where downtime is costly. Karmakar elaborates, "Machine learning algorithms, meanwhile, optimise robotic processes by analysing data from robots performing similar tasks, enhancing overall productivity. Altogether, AI-driven advancements are making robotics more efficient, cost-effective, and user-friendly, accelerating the adoption of robotics across diverse industries."

Today, robots equipped with AI are improving production lines by performing tasks such as quality inspection, assembly, and material handling with greater accuracy and speed. Another example is the way they are transforming the logistics and supply chain sector by optimising warehouse operations, automating inventory management, and improving delivery efficiency. Gandhi states, "AI algorithms also help robots make better decisions in real-time, allowing them to adapt to changing conditions and perform complex tasks with humans safely and efficiently, making them valuable partners in various industries. ML enables robots to learn from experience, improving their performance over time. This is particularly useful in dynamic environments where robots need to adapt to new tasks and conditions."

Cobots: Aiding uptake

The growth of the robot market in India faces challenges such as high initial investment costs, limited awareness about automation benefits, and the need for skilled labour to manage robotic systems. However, Singh believes, SMEs can certainly take advantage of robots and cobots. Cobots, in particular, offer a low-barrier entry for SMEs, as they are designed to work alongside human operators, enhancing productivity without requiring significant changes to existing workflows.

Technology companies are working towards offering affordable and practical automation and robotics solutions for the entire industry. Gandhi adds, "SMEs in India can definitely take advantage of robots and collaborative robots. By automating repetitive and mundane tasks, SMEs can improve productivity and focus their human workforce on more complex and value-added activities. Cobots are generally more affordable, and can be easily reprogrammed, repurposed, and integrated than traditional industrial robots, making them suitable for SMEs with limited budgets. They are also designed to work alongside humans safely, reducing workplace accidents and improving overall safety standards."

Automation has traditionally been associated with only the largest manufacturers, but it can also help smaller companies become more resilient, adaptable, and efficient. Many SMEs have successfully deployed cobots for tasks like assembly, material handling, and pick-and-place operations, achieving substantial cost savings in a relatively short time. Karmakar explains, "Cobots offer unique advantages by working directly alongside human operators, sharing tasks, and leveraging AI to learn and adapt. This allows companies to automate repetitive, hazardous, or physically demanding tasks, enhancing safety and efficiency in smaller-scale operations."

As robots and automation become increasingly common on factory floors, companies are focusing on enhancing worker safety by assigning robots to handle dangerous and repetitive tasks. For instance, robots are utilized in hazardous environments, like narrow elevator shafts, to carry out tasks such as drilling and scanning surfaces with precision, reducing human error and minimising risks. "By taking over high-risk tasks, robots allow workers to focus on more skilled, meaningful jobs, contributing to a safer, healthier, and more productive work environment. Ultimately, automation is enhancing worker safety and making factories more efficient and sustainable," explains Karmakar.

Changing employment landscape

While automation may reduce the need for certain manual and repetitive tasks, it also creates opportunities for new types of jobs that require different, advanced and creative thinking skill sets. Gandhi explains, "Automation is expected to reduce the number of low-skill jobs but increase the demand for high-skill roles in programming, maintenance, and management of automated systems. By automating routine tasks, companies can improve productivity and efficiency, potentially leading to business growth and the creation of new job opportunities. While some jobs may be displaced, new roles in AI, robotics, and data analysis will emerge, requiring a workforce with advanced technical skills."

For preparing the workforce, he believes, reskilling and upskilling is the way ahead. "Companies should invest in training programs to help employees acquire new skills relevant to automation, robotics AI, and data analytics. Encouraging a culture of continuous learning and adaptability within the organisation can help employees stay relevant in a rapidly changing technological landscape. Partnering with universities and technical institutes to develop curricula that align with industry needs can ensure a steady pipeline of skilled workers," opines Gandhi.

Walia adds, “Humans may have their own limitations. But, if we have the right robot for the precise applications and adequately trained human resource, then companies can vastly improve their efficiency, productivity, outputs and cycle time; thus reducing the per unit cost."

While automation may reduce demand for certain manual roles, it also drives the need for new roles focused on the design, programming, maintenance, and management of robotic systems. This shift emphasizes the importance of workforce training and education, as companies will need to invest in programs that equip employees with the skills required to work alongside robots. Karmakar observes, “The booming robotics sector is also generating job opportunities in specialised roles, such as robotics engineers, robot design engineers, application engineers, and smart factory designers, further solidifying India’s role in the evolving automation landscape.”

As the adoption of automation grows in the country, AI-driven robotics will open new ways for people to work alongside robots. Karmakar opines, “Advances in AI interfaces, including generative AI, allow users to program robots through natural language, making it easier for those without coding skills to operate them. This lowers the entry barrier, enabling a wider workforce to engage with robotics, which is particularly valuable for small to medium-sized businesses facing labor shortages."

Demand boom to come

According to Singh, several trends will shape the future of the robotics market, including advancements in AI and machine learning, increased integration of robots with IoT, and the growing adoption of autonomous mobile robots (AMRs). Additionally, the shift towards sustainable and energy-efficient technologies will drive innovation in robotics.

Gandhi adds, "We can estimate that the trend for cobots to work closely with humans will accelerate. Currently, cobots and AMRs can work closely with humans without requiring specific safety enclosures or paths. The next big step in this is expected to be cognitive robots, which are equipped with multiple sensors and AI and have a better cognition of their environment and thus work intuitively."

The future of robotics in India looks promising, with significant growth expected across various sectors. According to a Statista report, the robotics market in India is projected to reach $ 446.70 million in 2024 and continue growing at a compound annual growth rate (CAGR) of 8.26 per cent to reach $ 664.40 million by 2029. "This growth is driven by advancements in AI, increasing automation needs, and supportive government policies. Also, India's thriving startup ecosystem is fostering innovation in robotics, with many new companies developing cutting-edge solutions," states Gandhi.

The long-term potential for robotics in India becomes more evident when compared to China, which has a similar population size. In 2023, China saw 276,288 annual robot installations—32 times higher than India's current peak. "The OECD forecasts India’s GDP will grow at a robust 6.5 per cent annually in fiscal years 2024 and 2025. The automotive industry, the largest consumer of robotics, has also announced several investment projects, primarily focused on expanding production capacity for electric vehicles and batteries," states Takayuki Ito.

As per International Federation of Robotics projections, robot installations in India are expected to continue growing through 2024 and 2025. However, a dip is anticipated in 2026 when the Production Linked Incentives scheme concludes. After that, the demand for robots will be fueled by the long-term projects that have already been announced

. Making India competitive India stands at a pivotal juncture in its industrial journey, where the adoption of advanced manufacturing technologies, including automation and robotics, is no longer optional but imperative. Doshi elaborates, "The global shift, driven by multinational companies (MNCs), offers a unique opportunity for India to become a significant player in the global supply chain. However, to meet these growing global expectations, Indian manufacturers must integrate automation, AI, and robotics into their operations. These technologies play a critical role in enhancing productivity, ensuring consistency in quality, and minimising errors—all essential factors for competing on a global scale." The global manufacturing landscape is experiencing a major transformation. AI, ML and robotics have moved beyond futuristic ideas to become the foundational elements of Industry 4.0, driving the evolution of production processes worldwide. As a manufacturing leader with global aspirations, India stands at a pivotal moment to harness these technologies and shape its future in this rapidly evolving ecosystem. Given the rapid advancements in next-generation robotics, the vision of fleets of autonomous robots assembling entire automobiles on fully automated production lines is poised to shift from science fiction to reality in the near future. Barriers to Growth

Related Stories

ABB India invests Rs 140 crore to expand LV motors capacity

ABB India launches rare earth-free IE5 motors for industry.

Read more

The human-machine symbiosis: Why Industry 5.0 is the future of manufacturing

Industry 5.0 marks a shift from pure automation to human-machine collaboration. Dijam Panigrahi, Co-founder and COO, GridRaster Inc, explains how technologies like robot rentals, cobots, AR/VR, and ..

Read more

Caliber Interconnects unveils AMRs and robotic handlers

Caliber’s AMRs are AI-driven, customisable automation solutions engineered for industries such as warehouse logistics, manufacturing, e-commerce fulfilment, healthcare, and automotive

Read moreRelated Products

Digital Colony Counter

Rising Sun Enterprises supplies digital colony counter.

Robotic Welding SPM

Primo Automation Systems Pvt. Ltd. manufactures, supplies and exports robotic welding SPM.

Heat Exchanger Scale Removal Compound -hesr-300

Hi There!

Now get regular updates from IPF Magazine on WhatsApp!

Click on link below, message us with a simple hi, and SAVE our number

You will have subscribed to our Industrial News on Whatsapp! Enjoy