Schedule a Call Back

Practical tips to make ACs more efficient and save energy

Technical Articles

Technical Articles- Feb 01,18

Related Stories

UNITED GRINDING and GF Machining merge to form UNITED MACHINING SOLUTIONS

The new entity will be one of the world's largest machine tool manufacturers with $ 1.5 billion in sales.

Read more

Kinetic Communications opens automated controller manufacturing line in Pune

The new advanced automated controller line in Pune leverages Industry 4.0 technology to drive high-speed, precision manufacturing for next-generation smart EV electronics.

Read more

Aimtron Secures Rs 1 bn ODM Deal with Leading US Infrastructure Firm

Aimtron, an Electronics System Design and Manufacturing (ESDM) company, has signed a Rs 975.5 million ODM deal with a US infrastructure leader to develop advanced, transformer-free UPS systems for g..

Read moreRelated Products

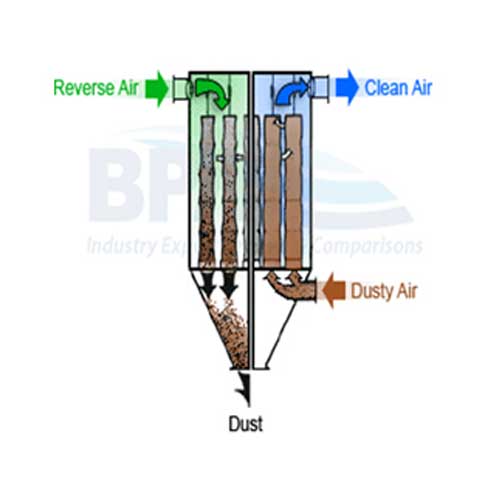

Reverse Air Bag House

ABR Enviro Systems offers a wide range of reverse air bag house.

High Quality Air Knife System

Superchillers offers high quality air knife system. Read more

Compact Cylinders -Vadvu Series

Vijay Air Control offers a wide range of compact cylinders -Vadvu Series