Schedule a Call Back

HRS Process offers energy efficient HRS FUNKE Plate Heat Exchanger

Technical Articles

Technical Articles- Nov 01,18

- NBR (nitrile-butadiene rubber): Universal use for water or oil applications

- EPDM (ethylene-propylene rubber): Uses for chemical compound which do not contain mineral oil and grease and also for water and steam application

- Flororubber (Viton): Uses for high temperature of vegetable oil, sulphuric acid and organic solvents

- Gasketed plate heat exchanger: It is the most widely used variant of PHE which consists of a set of embossed plates fitted adjoining to each other and each plate separated by a gasket. This is used for most oil, water, etc applications. The gasket, which is mechanically secured or glued onto every plate, ensures that the flow gaps are securely sealed to the outside and from the second medium involved in the heat exchange. Also for different compositions and corrosive properties, the best fit material of construction of plates and gaskets are used.

- Brazed plate heat exchanger: It consists of embossed plates, fit into one another and vacuum brazed with copper, nickel or stainless steel to form a compact and pressure proof unit. It is designed for applications like cooling of lube oil, condensing in refrigeration plant

- Cladded plate heat exchanger: This is a well researched in-house design where the fixed plate and pressure plates are cladded with stainless steel or similar metals to make the outer surfaces compatible with process and utility fluids. This is effective in food, dairy, brewery and similar hygienic applications.

Related Stories

HRS Process exhibits at Chemprotech 2022 expo in Mumbai

HRS Process Systems Ltd recently participated at Chemprotech 2022, part of the Chemspec expo organised by VA Exhibitions & Chemical Weekly magazine from April 20-21 in Mumbai. Chemprotech is an inte..

Read more

HRS Process showcases energy-efficient heat exchangers at P-MEC

HRS Process Systems Ltd (HRS PSL) showcased its latest range of energy-efficient heat exchangers and heat exchanger systems at P-MEC 2021 - the first in-person event organised by Informa Markets pos..

Read more

HRS PSL displays heat transfer solutions for pharma industry at CPhI P-MEC 2019

The company also exhibited HRS FUNKE plate heat exchangers (PHE) and range of heat exchanger based systems.

Read moreRelated Products

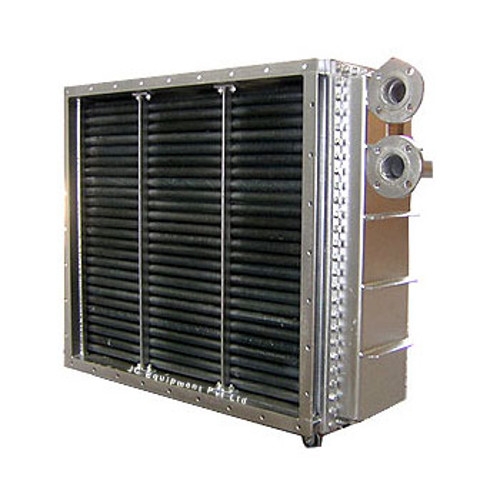

Finned Tube Heat Exchanger

Simon Coil And Heat Exchanger manufacturers

finned tube heat exchangers.

Corn Flake Dryer Heater

Mark Engineers offers a wide range of heat exchanger for corn flake dryer heater.

Solar Water Heaters

Focusun Energy Systems offers a wide range of solar water heaters for boilers.