Schedule a Call Back

Gleason to showcase latest products for cylindrical and bevel gears at Motion+Power Technology Expo 2019

Technical Articles

Technical Articles- Sep 18,19

Related Stories

The Showstoppers at IMTEX 2023

With 991 exhibitors and more than 96,000 visitors from 23 countries, IMTEX 2023 was a showstopper for the manufacturing industry in India. Rakesh Rao lists here companies who displayed their cutting..

Read more

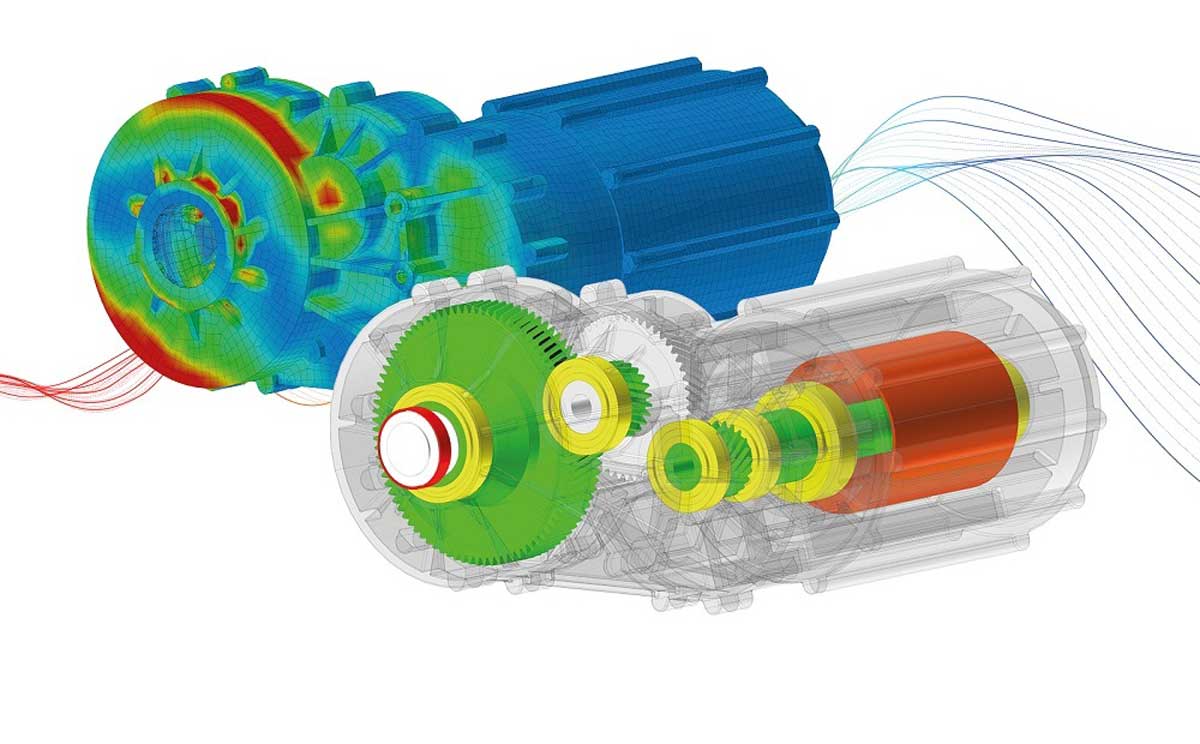

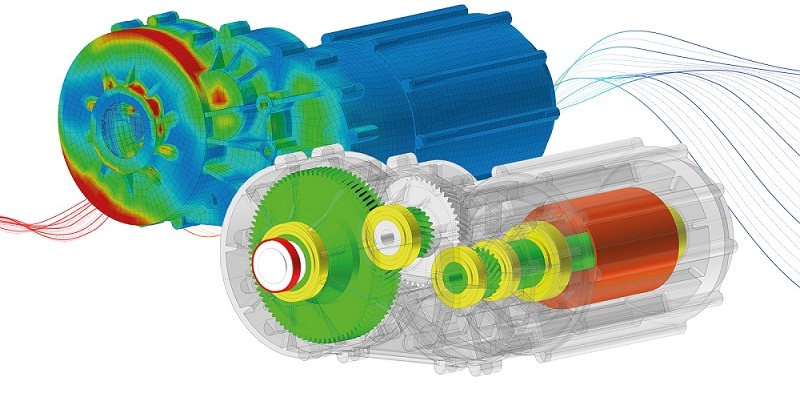

KISSsoft and RecurDyn hosts live session for e-drive design

Electric vehicles could represent up to 70 per cent of all cars by 2050. To ensure the acceptance of their vibrational and acoustical characteristics, profound NVH (noise, vibration, and harshness) ..

Read more

KISSsoft and RecurDyn hosts live session for e-drive design

The session presented a common and continuous solution to design, analyse and optimise the NVH (noise, vibration, and harshness) behaviour of a gearbox used in an e-drive system.

Read moreRelated Products

Auto Wheel Hub Bearings

Kasuma Auto Engg Pvt Ltd offers a comprehensive range of Auto Wheel Hub Bearings.

Gear Lever Kits

B S Industry offers a wide range of gear lever kits.

Automotive Gear

Matrix Precision Engineering offering a personalized array of automotive gear.