Schedule a Call Back

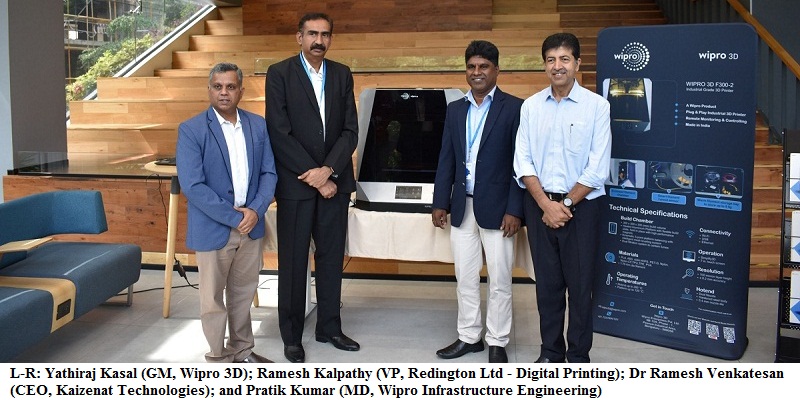

Wipro 3D launches indigenously developed industrial grade 3D printer

Industry News

Industry News- Dec 02,22

Related Stories

Avians High-Speed Clean Room Doors: Advancing Contamination Control

Avians high-speed clean room doors are redefining contamination control in sensitive environments such as pharmaceuticals, electronics, and food production with rapid operation, energy efficiency, a..

Read more

6 Nonnegotiable requirements for your smart factory transformation

The smart tech world is seemingly never-ending, but a few essential staples create an unshakable foundation. Here, Emily Newton suggests six essential ingredients for a transformation to smart facto..

Read more

Unique capabilities of edge computing in IoT

IoT edge computing projects allow people to benefit from advantages associated with both technologies, letting them tap into many unique capabilities, says Emily Newton.

Read more