Schedule a Call Back

Avians High-Speed Clean Room Doors: Advancing Contamination Control

Articles

Articles- May 28,25

Related Stories

Tamil Nadu Signs 158 MoUs Worth Rs 438.44 Bn at TN Rising

State secures major investments across aerospace, semiconductors and advanced tech.

Read more

Sun Pharma Eyes US Expansion Amid Tariff Uncertainty, Strong Q2

India’s top drugmaker posts solid Q2 results; weighs US factory expansion

Read more

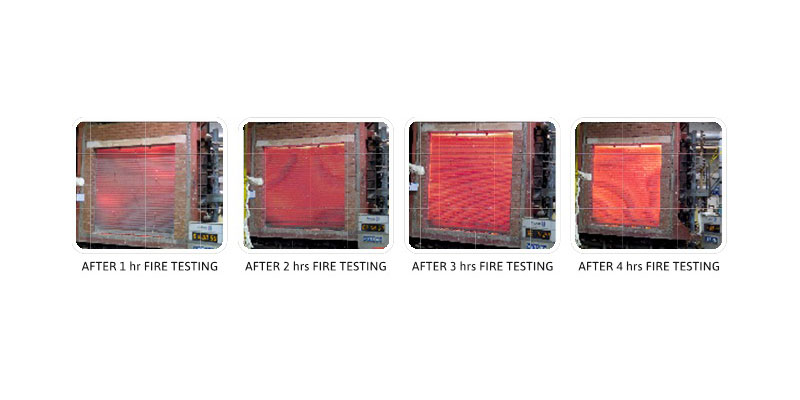

Fire-Rated Rolling Shutters: Why Fire Resistance Matters

CBRI & NABL approved for 4 hours fire resistance: Tested and validated by Central Building Research Institute (CBRI) Govt. of India Renowned Lab and NABL accredited labs for proven reliability. Prov..

Read moreRelated Products

Dock Leveller

Besto Material Handling Equipments offers a wide range of dock leveller.

Multi Tire

SCI Storage Solution offers a wide range of multi tire.

Industrial Lifting Equipment

Rana Material Handling Equipments Pvt Ltd offers a wide

range of industrial lifting equipment.