Schedule a Call Back

70% of Indian & APAC warehouses likely to embrace workflow automation by 2024

Industry News

Industry News- Nov 27,23

Related Stories

How MNCs are strategising to capture market in India

Today, the Indian MNC scene is changing vastly, with many new ones setting up shop in India. With China becoming less attractive, India is becoming the go to place, writes R Jayaraman and Firoz S Ri..

Read more

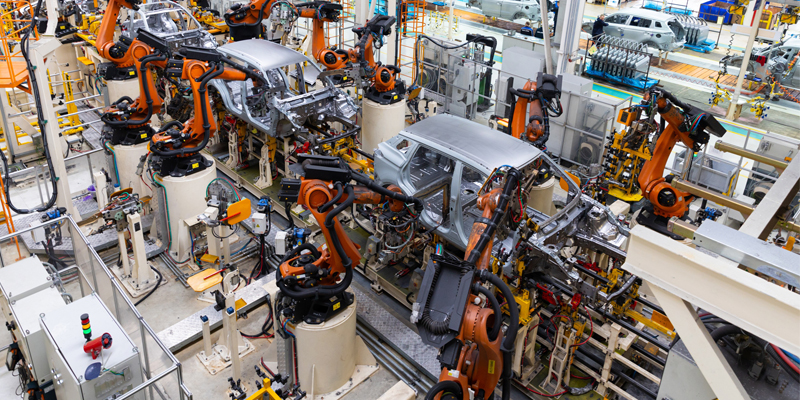

Smart Factories in India: Reality or Distant Dream?

As India moves toward its goal of becoming a $7 trillion economy by 2030, embracing smart manufacturing technologies will be crucial for achieving this ambitious target, writes Rakesh Rao. But, is t..

Read more

Driving Efficiency: Schmalz Gripping Systems for India's Manufacturing Future

As the market demands speed, agility, and reliability, Schmalz gripping systems are enabling the next generation automation of Indian manufacturing sector.

Read moreRelated Products

Dock Leveller

Besto Material Handling Equipments offers a wide range of dock leveller.

Multi Tire

SCI Storage Solution offers a wide range of multi tire.

Industrial Lifting Equipment

Rana Material Handling Equipments Pvt Ltd offers a wide

range of industrial lifting equipment.