Schedule a Call Back

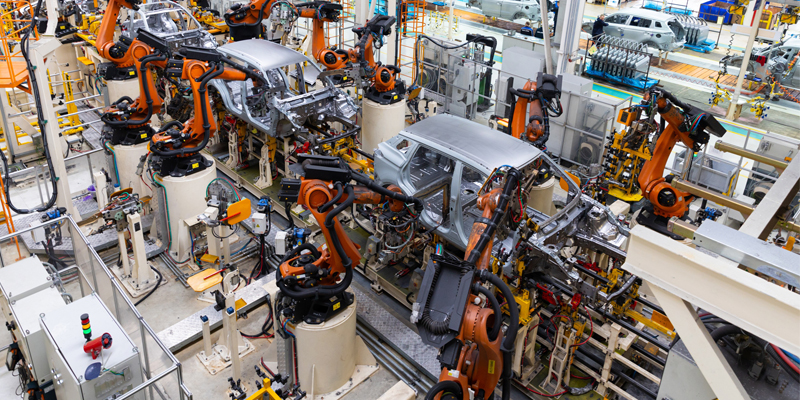

Smart Factories in India: Reality or Distant Dream?

Articles

Articles- Jul 28,25

Related Stories

Budget Expectation: Why Materials, Data and Governance Will Shape Manufacturing

India’s manufacturing growth hinges on digitalisation, material self-reliance, and policy clarity to strengthen resilience and global competitiveness, says S Sunil Kumar, Country President, Henkel..

Read more

India’s Manufacturing Reset in an Uncertain World

Global manufacturing is being reshaped by volatility and disruption. This release outlines how India is strengthening depth, resilience and capability to emerge as a long-term manufacturing partner,..

Read more

Project execution in a VUCA world: Mitigating cost and time escalation

Projects today must succeed despite uncertainty, not in the absence of it. Project execution now demands resilience, digital intelligence and lifecycle integration to control cost and schedule risks..

Read moreRelated Products

Compact Fmc - Motorum 3048tg With Fs2512

Meiban Engineering Technologies Pvt Ltd offers a wide range of Compact FMC - Motorum 3048TG with FS2512.

Digital Colony Counter

Rising Sun Enterprises supplies digital colony counter.

Robotic Welding SPM

Primo Automation Systems Pvt. Ltd. manufactures, supplies and exports robotic welding SPM.