Schedule a Call Back

The 3D metal revolution

Articles

Articles- Dec 24,24

Source: Horizon Grand View Research

Real-world impact

During the COVID-19 pandemic, when supply chains were

disrupted globally, Amace Solutions demonstrated the power of 3D metal

printing. In just 20 hours, they designed, printed, and delivered critical

ventilator parts. Dr Vishwas R Puttige,

CEO, Amace Solutions, shares his experience, “A customer urgently required

ventilator parts. Within 20 hours, we managed to generate a quotation, receive

a purchase order, print the required parts, and ship them. This demonstrated

the speed and efficiency of 3D printing.”

This rapid response isn’t limited to medical

emergencies. Amace also played a pivotal role in India’s Chandrayaan-3 mission.

The Pragyan rover, which marked India’s lunar success, featured wheels etched

with the ISRO logo and the national emblem, crafted with unmatched precision

using 3D printing.

The automotive industry, too, has embraced this

innovation. Companies like Bajaj Auto and Hero MotoCorp use 3D metal printing

for rapid prototyping and design validation. Dr Puttige highlighted a standout project, “We collaborated with an

electric motorcycle startup to produce 3D-printed components for three

motorcycles in just 15 days. The assembly process took another 15 days, and

within 30 days, the entire project was completed. One of these motorcycles set

a Guinness World Record by covering over 14,000 kilometers across India without

any issues.”

Addressing challenges

Despite its advantages, 3D metal printing faces

challenges. Yathiraj Kasal, General

Manager and Business Head, Wipro 3D, elaborated on these hurdles:

?

Complex

geometries: The enhanced design possibilities of 3D printing often result

in geometrically complex features. Machining supports for these intricate

designs and ensuring no unfused powder remains trapped in internal channels is

a significant challenge.

?

Material

limitations: The range of materials suitable for 3D printing is still

limited compared to traditional manufacturing. Designers must account for

material availability during the design phase to avoid delays or surprises

during production.

?

Dimensional

accuracy: Achieving the necessary dimensions and tolerances for functional

requirements remains a critical focus area.

Recent trends

The field of 3D metal printing is constantly evolving.

Kasal highlights several recent trends shaping the industry, “Multi-material printing

is enabling the integration of diverse materials in a single component,

enhancing functionality and performance for industries like aerospace and

healthcare. Multi-laser systems are reducing print times, making large-scale

production more practical and efficient.”

Engineers are also adopting lightweight designs,

inspired by nature, to minimise material use while maintaining strength,

benefiting sectors like automotive and aerospace. Additionally, component

consolidation allows multiple parts to be combined into a single unit,

simplifying assembly and cutting costs.

These trends showcase the growing impact of 3D metal

printing on innovation and manufacturing efficiency across industries.

The future

Additive manufacturing is revolutionising the metalworking

industry by offering unprecedented design freedom and efficiency. Amit Raina, Country Manager-India,

Dormer Pramet, comments, “Traditional manufacturing methods often result in

significant material wastage, especially during machining, where excess

material is removed to achieve the final shape. In contrast, 3D printing

minimises waste by constructing parts layer by layer, using only the exact

amount of material required. This precision not only cuts down on waste but

also reduces costs and improves sustainability.”

Additionally, 3D printing enhances production speed by

enabling rapid prototyping and quick design iterations. This acceleration of

the product development cycle allows manufacturers to bring products to market

much faster than with conventional methods, making it an invaluable tool for

industries that prioritise speed and innovation.

Customisation

and technological advancements

The ability to produce customised parts on demand is

another transformative aspect of 3D metal printing. This capability is

especially valuable in industries such as healthcare and aerospace, where

specialised, tailored components are often needed. 3D printing makes it easier

and more cost-effective to meet these niche demands, opening the door for

highly personalised manufacturing solutions.

Looking to the future, breakthrough technologies in 3D

metal printing are expected to revolutionise the industry even further.

Industry leaders, like Fronius, are excited about two key advancements that

promise to reshape manufacturing processes.

One is the closed-loop feedback system, which allows

for real-time process control and material characterisation. This system will

improve both precision and quality assurance, ensuring manufacturers can

achieve greater reliability and efficiency in their production.

Another promising technology is Cold Metal Transfer

(CMT), exemplified by the Fronius CMT Additive Pro process. This system

delivers high deposition rates and precise molten pool control, making it ideal

for producing high-quality, complex parts, especially when working with

difficult-to-weld alloys. The CMT process is particularly suited for

high-volume production and applications that demand tight tolerances, further

expanding the capabilities of 3D metal printing.

Expanding applications

As the technology matures, its applications continue to

grow. Sectors such as healthcare are leveraging 3D printing for custom implants

and prosthetics. Aerospace manufacturers are producing lightweight,

high-strength components, while the defence industry is exploring its potential

for rapid prototyping and low-volume production.

India’s 3D printing ecosystem is steadily expanding,

with companies like Amace Solutions, Wipro 3D, and others leading the charge.

The country’s focus on Aatmanirbhar Bharat and Make in India are further

driving the adoption of advanced manufacturing technologies. Investments in

research, infrastructure, and skill development will be crucial in realising

the full potential of 3D metal printing.

Conclusion

3D metal printing is India’s ticket to the future of manufacturing. Its ability to defy traditional constraints, reduce time-to-market, and enable customisation makes it a game-changer. As industries continue to innovate and adopt new technologies, India stands on the brink of becoming a global powerhouse in additive manufacturing. The journey has only just begun, and the possibilities are limitless.

Related Stories

Indian manufacturing sector enters a golden age: N Chandrasekaran

Tata Group plans to create 500,000 manufacturing jobs over the next half-decade, said N Chandrasekaran, Chairman of the conglomerate, in his New Year message to employees.

Read more

Elfonze Technologies expands new office in Bengaluru

The milestone celebrates the company’s remarkable growth and highlights commitment to innovation, collaboration, and employee well-being.

Read more

The 3D metal revolution

India is rapidly emerging as a frontrunner in the world of 3D metal printing, a technology that is reshaping the way industries approach manufacturing. From aerospace to automotive, healthcare to de..

Read moreRelated Products

Fire Alarm

Safe Zone is prominent traders and suppliers of the industry, offering a wide range of wireless fire alarm.

Read more

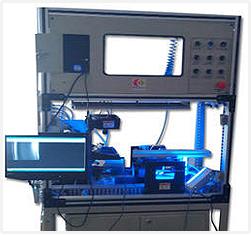

Sorting Automation Systems

Renovus Vision Automation offers sorting automation systems.

Read more

Manual Bagging System

Alligator

Automations provides a wide range of manual bagging systems.