Schedule a Call Back

Our India-specific solutions can stand challenging environments: Vishal Agarwal

Interviews

Interviews- Feb 22,25

Related Stories

Germany's Barnes Molding Solutions Opens $30 Mn Greenfield Facility in Pune

New Chakan plant strengthens Barnes Molding Solutions’ Asia strategy with local manufacturing and service capabilities.

Read more

Rosti Opens High-Precision Injection Moulding Plant in India

Rosti has recently inaugurated a high-precision injection moulding and contract manufacturing facility.

Read more

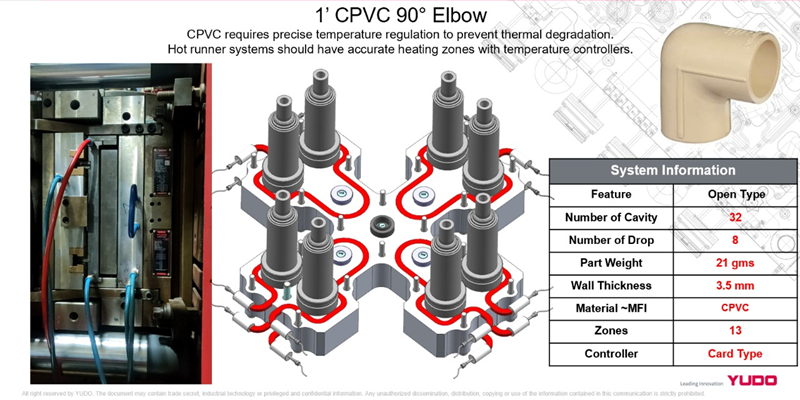

Yudo India rolls out Hot Runner Systems for CPVC to enhance local manufacturing

India is among the largest consumers of CPVC pipe fittings globally.

Read moreRelated Products

Rubber Sheets Material

Talbros Sealing Material Pvt Ltd offers a wide range of rubber sheets materi Read more

Rail Rubber Pad

Chamunda Enterprise offers a wide range of rail rubber pad.

Insulation Polyester Film

TMA International Private Limited offers a wide range of insulation polyester film.