Schedule a Call Back

Dies & moulds are the heart of the manufacturing industry

Interviews

Interviews- Jan 29,24

- Long lead time for die blocks

- Currently, most of the tool rooms are booked for next 12 months

- The lack of knowledge of latest technology/ practises being used in developed countries

- The lack of collaborative approach among the tool makers

Related Stories

India’s Manufacturing Mission: What Make in India Got Right and Wrong

A decade after its launch, Make in India shows sectoral progress but structural gaps remain. As global manufacturing turns VUCA, the next phase must focus on value addition, jobs and ecosystems, say..

Read more

India’s Manufacturing Mission: What Make in India Got Right and Wrong

A decade after its launch, Make in India shows sectoral progress but structural gaps remain. As global manufacturing turns VUCA, the next phase must focus on value addition, jobs and ecosystems, say..

Read more

IMTEX Forming celebrates human ingenuity & machine intelligence: Jibak Dasgupta

In this interview with Rakesh Rao, Jibak Dasgupta, Director General & CEO, Indian Machine Tool Manufacturers' Association (IMTMA), explores trends in the machine tools industry and shares some highl..

Read moreRelated Products

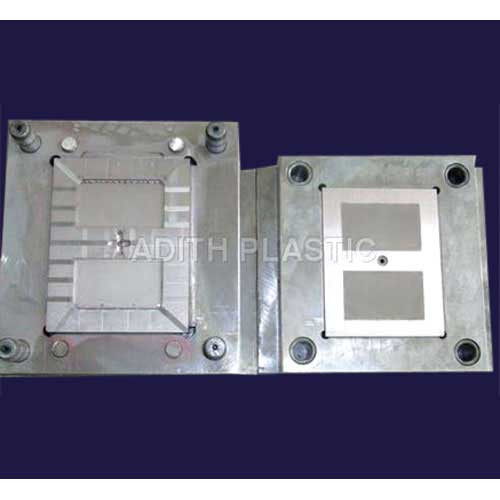

Industrial Moulds

Adith Plastic offers moulds for industrial electronic parts.

Industrial Plastic Moulding Dies

Adith Plastic offers a wide range of industrial plastic moulding dies.

Component Moulds

Innovative Moulds & Dies offers a wide range of plastic component moulds. Read more