Schedule a Call Back

Millennials to drive Indian manufacturing

Interviews

Interviews- Dec 01,17

Sabby Gill, Executive Vice President International, EPICOR Software (UK) Ltd asserts that millennials will take India’s manufacturing sector to the next level. In an exclusive interview to Manish Pant, Gill is very upbeat on the firm’s recent alliance with the supply chain solutions provider Redington India. The Texas-based $900 million provider of enterprise application software and services to manufacturing, distribution, retail, and services sectors, EPICOR sees a humongous growth opportunity in India’s 32 million MSMEs.

What brings EPICOR to India?

We believe that we are at an important juncture from a local Indian market perspective. When you look at the key initiatives being run by the Indian government like Make in India and Digital India, a fair amount of work being done in relation to make business easier in the country. And now the government wants India to be in top-50 in the World Bank’s Ease of Doing Business Index so that it can continue that momentum.

Interestingly enough, one of the possibilities that have been identified of getting to the top was around logistics. By simplifying logistics and company registrations to allow organisations to move around more freely, and building ports and other infrastructure, is a huge opportunity for manufacturing.

With the introduction of GST, though there are still some things that need to be ironed out, the product that we have today is GST ready. We released it back in May. We believe that not only is the market right, but we also have the right technology and type of products that manufacturers require here.

Also, another important aspect here is the workforce. At 400 million, India now has the largest number of millennials in the world. Millennials expect a totally different experience when they come into the workplace than anybody else does. They want collaborative and social tools that are easy to understand, use and deploy. They want applications that you don’t have to customise. They also want to be able to put in their own flavour and tailor the user interface, dashboards, and that sort of things.

You take all of those different aspects into account. We believe that with our industry expertise, interface, products, technology, architecture and the fact that we are GST-compliant, we have the type of experience that millennials require. We also have that deep industry vertical expertise to tackle those 32 million organisations that fall under the micro, small and medium enterprises (MSME) here.

What is the potential for Enterprise Resource Planning (ERP) solutions in the Indian manufacturing space?

Consumer expectations are very different today than they were 10-15 years ago. The consumer wants a certain type of experience and the ability to produce equipment that way. The millennial element has something to do with that. If manufacturers don’t adapt very quickly to consumer requirements and technology to gain better control of their supply chains, then they are not going to be able to cater to that workforce.

By 2025, 70% of the workforce within organisations would be millennials. They are also the potential consumers of the products that you manufacture. We believe that with our applications and the strength of EPICOR brand, that’s what we will be catering to.

What are your medium and long-term plans for India?

In the medium-term, it is about getting brand recognition and our footprint out there, and acquiring customers and helping them deploy the applications. The partnership that we have with Redington gives us instant penetration across the market. We want to get as many customers adopting EPICOR as possible.

With 20,000 customers already, we have lots of case studies and references. We are ready to believe that the opportunity is humongous. We don’t think any other vendor out there today has got to the number one stage. We believe there is ample opportunity for both local vendors and everybody else. But we want to stay focused on our core strength in our industry verticals to ensure that we penetrate the market as much as possible.

How do you see your alliance with Redington helping you expand your footprint here?

With someone like Redington who has 23,000 channel partners, we get instant footprint in relation to having access to that network. They are people who already know the market and customers. However, among those channel partners, not everyone understands ERP. Therefore, we will selectively look at the right number of partners within their entire portfolio that we believe could go out and sell the value of ERP applications. And then we will target those specific customers. The primary route to the market for us in India is through Redington.

The ERP industry is expected to be worth $50 billion by 2020. What industry segments are likely to be the primary drivers behind this increase and what is your own outlook for EPICOR?

From an overall market perspective, the government or public sector always tends to be one of the largest because governments tend to spend more on infrastructure. Especially here in India, with all those different initiatives such as smart cities programme, I would say that it is probably where the biggest portion of the industry’s $50 billion is going to come from.

Construction is going to be another area. Again, a lot of it is associated with the government’s construction programmes. In addition to that, I do believe it will be manufacturing. A lot of manufacturing is moving away from China because the costs there are getting higher every year. There is pressure on organisations to look outside of China, and potentially move to other places like Thailand, Vietnam, Indonesia and India. With the initiatives that the Indian government is putting into place, we are witnessing very mature organisations and operations entering India, which we find really attractive.

Within manufacturing, EPICOR is focused on elements around aerospace and defence, automotive and ancillaries, capital equipment and manufacturing, electronics, engineered-to-order, metal fabrication, food and beverage, industrial machinery, instruments and controls, medical devices, print and packaging, pharmaceuticals, and rubber and plastics. That’s a lot! What we are saying is that we are going to stay and remain focused from a manufacturing sub-vertical sector perspective.

How are technological disruptions forcing manufacturers and vendors to overhaul their processes?

When you think about some of those mega-trends like virtual reality, 3D printing, data analytics, robotics, automation, etc., there are lots of things that manufacturers need to worry about today because at some point those things will be coming in the future. When you are making a decision around an ERP, you are not making a decision for today, you are making a decision about the future. Most ERP applications are installed for anywhere between eight, ten and twelve years.

EPICOR has been around 40 years and we have continued to advance in all our technologies. We have customers who were using augmented reality, machine learning, robotics, automation and IoT, and they are already talking about Industry 4.0. The latest version of our analytics package takes the way information is consumed to the next level. That’s why the focus we have on these industry sectors is so important; we need to make sure that we don’t become a broad-brush ERP vendor.

How can ERP systems help MSMEs and start-ups in proactive decision making? Do you have any plans to tailor-make some cost-effective solutions for those segments?

What we do is we provide ‘the best solutions’ because there is no historical perspective. They are greenfield sites. As long as they fall into the key industry sectors that we cater to, the implementation, experience and everything else that they have will be based on best practices of other organisations that fall into those same sectors and our own 40-year history. A lot of times, their requirements are out-of-the-box. Greenfield sites and some of the startups are, therefore, easier to service.

The second piece to your question is about the choice of deployment. The fact that we have the ability to offer on-premise, managed service, hosted and cloud solutions, gives MSMEs and start-ups multiple choices for deployment. From a cost perspective, charging a monthly subscription on a cloud solution is how you would ensure that they do not incur a lot of capital cost upfront. It’s almost like pay as you go model. The flat fee paid by the user covers the application as well as the infrastructure hosting it.

What kind of headcount additions are you looking at making in India?

Today in ITC, we have about 425 people on 48,000 square feet are. By the end of February 2018, we are taking on an additional 32,000 square feet. And by the end of next year we would have hired another 100 people.

In addition to that, we have a sales and marketing organisation that we have literally hired in the last few months to support Redington. We will scale-up the organisation depending on how well the Redington plan comes through. If Redington hits the ball out of the park and does very well with the numbers, then we will absolutely make that investment in infrastructure to support the business. We are 3,900 employees globally. If you take up our 525 employees in India, that is over 14 per cent of our total global workforce. I cannot think of any other ERP vendor that has made that sort of investment in its overall employee population in India.

Related Stories

Roadmap to digital transformation for Indian SMEs

India’s SME manufacturing sector is at a crossroads, poised to embrace digital transformation, sustainable practices, and innovation. However, challenges like legacy systems and skilled labour sho..

Read more

Embracing Digital Transformation

India’s SME manufacturing sector is at a crossroads, poised to embrace digital transformation, sustainable practices, and innovation. However, challenges like legacy systems and skilled labour sho..

Read more

India's manufacturing renaissance: Rishi Aggarwal

Creating a pipeline of skilled labour is needed for the success of Make in India. This affects traditional and emerging sectors like electronics or advanced engineering. With demand for technical ex..

Read moreRelated Products

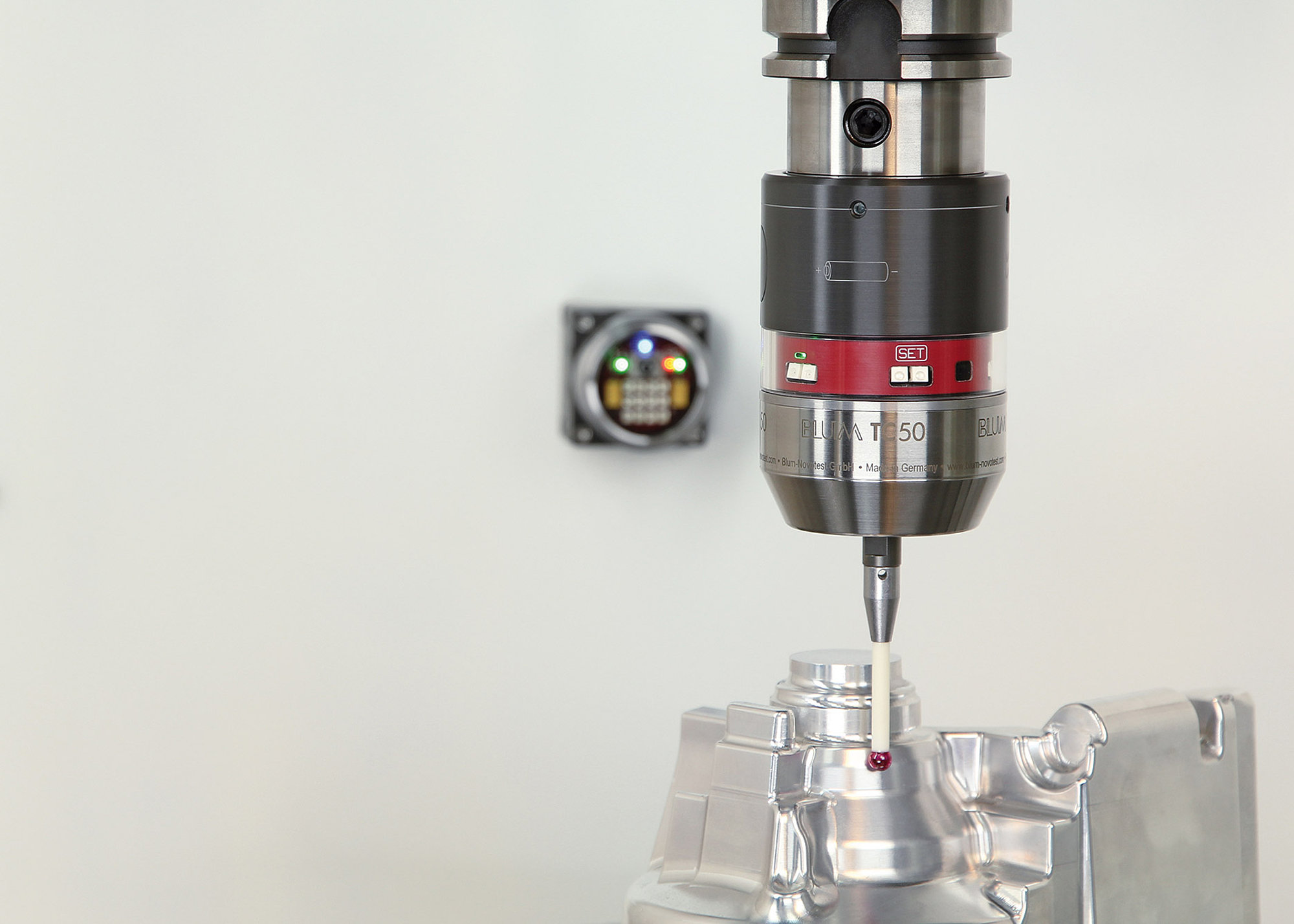

Measurement Software

Blum-Novotest Measuring & Testing Technology Pvt Ltd offers a wide range of measurement software.

Twincat Controller Redundancy Software

Beckhoff Automation offers TwinCAT Controller Redundancy – the software-based solution protects plant uptime through redundant control operation.

Software System

Beckhoff’s TwinCAT CNC offers the option to implement interpolation with up to 32 simultaneously interpolating axes.

Read more