Schedule a Call Back

Demand for industrial burners has been very dynamic

Interviews

Interviews- May 01,18

- When the fuel prices are in “downward trend”, furnace oil / HSD burners are in good demand.

- When there fuel price are in “increasing trend”, producer gas & coal gas burners are in good demand.

- As availability of piped gas, LPG bullets (fuel storage units) & environmental regulations are becoming stringent, there is good demand of Natural gas / LPG burners.

- There are factories which are generating by-product fuels such as biogas, coke oven gas , Blast furnace gas & hydrogen gas. In such industrial units, there is good demand for utilising such gases in burners & reduce their energy bills.

- There are also requirements for burners for fuels such as pyrolysis oil, syn-gas, vent gas, industrial sludge which are generated from waste products and can be used to generate useful energy & reduce environmental degradation.

Related Stories

Jasmino Corporation acquires German firms, HAW Lining and GBT Buecolit

HAW Lining, a pioneer in rubber linings, has been instrumental in industrial corrosion protection for over 125 years, offering critical solutions to global industrial powerhouses.

Read more

CPP installs tallest FRP stack liner for thermal power plant

Tackling emissions from the thermal power sector in India is an important priority for achieving India’s energy transition goals

Read more

CRISIL: Lower oxygen supplies to impact SMEs in key five sectors

These 5 sectors - metal fabrication, automotive components, shipbreaking, paper, and engineering - typically do not have captive oxygen plants and source their need through merchant suppliers for op..

Read moreRelated Products

Biomass and Coal Fired Spreader Stoker Boiler

Sitson India Ltd offers a wide range of biomass and coal

fired spreader stoker boiler

Coil Type Boilers - VRS Series

Maxima Boilers Private Limited offers a wide range of coil type boilers - VRS Series

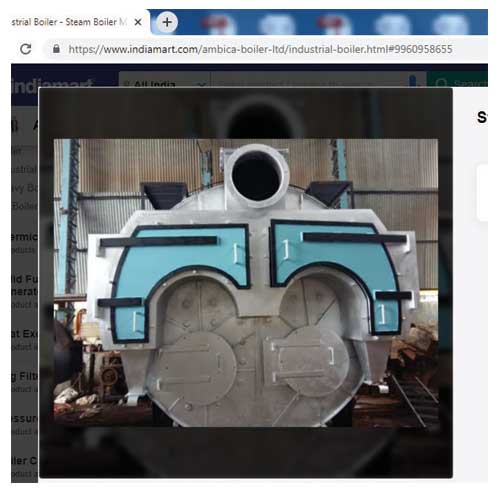

Steam Boiler

Ambica Boiler offers a wide range of steam boiler.