Schedule a Call Back

What’s lifting mobile hydraulics?

Industry News

Industry News- Mar 02,22

Mobile applications accounting for about 60% of the total hydraulic market. Trend towards electrification is forcing vehicle OEMs to search for efficiencies in the system in order to extend limited battery life. In this interaction, Brianna Jackson - a Research Analyst in the Industrial Automation team of Interact Analysis (IA) - draws on her extensive research in the mobile hydraulics sector to answer some of the relevant questions about the industry:

What’s triggered a renewal of this report right now?

It is back by popular demand! The last edition was in 2019 and, in 2022, it is customer interest that has caused us to update it.

We have focused on mobile hydraulics as that’s where the interest is. Mobile applications account for maybe 60% of the total hydraulic market, with industrial applications making up the other 40%. But mobile is where the growth is, and where the real innovations are happening.

The driver is electrification. Hydraulic technology has one big advantage: power density. It also unfortunately has one big drawback: inefficiency. When hydraulics are mounted on a diesel powered vehicle, inefficiency is not ideal, but it is tolerable for operators. If hydraulics are to be mounted on battery powered vehicles, however, the inefficiency problem needs to be solved.

What’s a single stand-out interesting fact that came out of the research for you?

The single most interesting thing I’ve learned about mobile hydraulics is how difficult it is to get higher efficiency products approved and into vehicles. A change to a vehicle is a huge risk for any hydraulic vehicle OEM. That’s because these vehicles have very delicate systems which rely on each other, and any problems missed at the testing stage are expensive given that vehicle production runs are in the thousands. Because of this, OEMs are inherently risk averse. Therefore, if a product only improves system efficiencies by (for example) 2-3% then, historically, they are unlikely to consider that to be a justification for a full overhaul of vehicle design.

However, what is interesting about the electrification trend is that it is forcing vehicle OEMs to search for efficiencies in the system in order to extend limited battery life. Hydraulics are highly energy intensive; they therefore represent the ‘low hanging fruit’ for vehicle OEMs looking for easy improvements to system efficiency.

How did the market do during 2021?

Our research is not finished yet, but I am confident that 2021 is up compared to 2020, and many of the companies I’ve talked to so far say they are on track to match their 2019 performance. In other words, we can pretty much safely say the market has recovered from coronavirus and the economic downturn it caused. A lot of that recovery has been driven by sales of hydraulics to the construction sector, particularly in China and Europe.

A key reason for this was that construction, being mostly outdoors, was one industry sector that was much less impacted, even in the countries that had the harshest of lockdowns. I think what happened in heavily locked down countries was that at first everything stopped. But then as government fiscal assistance kicked in during the height of lockdowns (during mid to late 2020), individuals and businesses realized that the sky wasn’t going to fall down, and many of them bought forward planned construction work – simply on the basis that it was one thing they could still at least go ahead with. An additional point is that interest rates were also slashed at the beginning of the pandemic. This led to significant capital expenditure: a core driver of new construction activity.

What about the short- to medium-term outlook in 2022?

For mobile hydraulics, 2022 is going to be all about supply chains. We had thought we were starting to see the end of supply chain issues. However, our research showed us this was incorrect. Sure, the market will see growth, but everyone is going to be struggling with their suppliers. One pump manufacturer told me the price of steel has gone up so much that it’s almost prohibitive. We’ve written recently about how high steel prices are impacting other sectors, such as warehouse automation. Well mobile hydraulics is being hit just the same. And it’s not just steel. Raw material prices are up across the board. This will, without a doubt, drive price rises in hydraulic systems.

The other big problem is freight costs, which are up hugely. Interestingly, this isn’t normally directly driving hydraulic component or system price increases. Instead, we’re seeing suppliers cover these costs with completely new shipping fees that are just layered onto the price. The implicit message to the customer being: ‘we don’t want to charge these prices, and we’ll reduce them just as soon as things go back to normal’. For now, though, even though the prices of the components themselves are not going up as a result of shipping, it all amounts to the same thing: the costs of hydraulic systems to end users are on the up.

One other interesting point: lead times are not so bad compared to other industries. In AC drives and motion controls, we’ve seen lead times rocket sometimes to as high as eight months as suppliers simply cannot get the parts they need. In mobile hydraulics the worst case we’ve heard of was lead times increasing from one to three weeks. It would seem that the problem is not that suppliers can’t meet demand, simply that they have to put prices up in order to do so. Why this is the case I am not quite sure, but I suspect one factor is that mobile hydraulic manufacturers tend to be located relatively near to where their customers – the vehicle OEMs – are based.

How about the longer-term five-year outlook?

It’s strong. Certainly, stronger than I had expected. Before this project kicked off, a lot of people told me that mobile hydraulics was an old-fashioned technology that was at risk of displacement. One thing I heard a lot, for example, was that electric actuators would widely replace traditional cylinders. But when I got into the research and spoke to multiple stakeholders across the hydraulics value chain, I realised that displacement is not the threat to hydraulics that it’s often made out to be. Sure, there’s product substitution in certain applications, but it’s no big trend. Meanwhile, the benefit mobile hydraulics has over newer solutions is two-fold: first – there’s still nothing that can compete on power density; and second – traditional components are significantly cheaper. The big thing for vehicle OEMs is total cost of ownership. And, if new product variants don’t have an RoI of two years or less (and mostly they don’t), then most OEMs will not be interested.

Tell me about one to watch

That’s easy: digital hydraulics. Having just said that I don’t think the traditional mobile hydraulics industry is ripe for disruption, there will be a level of disruption for sure, and I think that’s most likely to come from digital hydraulics. Digital hydraulics is about the rapid on off switching of valves in a hydraulic system. It helps to better regulate flow which improves efficiencies. The term ‘digital’ is used in this context simply because of the on/off (1/0) parallels with digital vs analog signals. This is an exciting product because of the efficiencies it brings to the system. In fact, it represents a potential step-change in efficiency, and thus may become a major enabler of electrification initiatives.

Digital hydraulics is one to watch because, of all upcoming hydraulic technologies, it has gained the most investment. One example is Artemis Intelligent Power. Danfoss always had a major stake in this company, but recently they took full ownership. If there is an industry disruptor for mobile hydraulics coming down the tracks, then digital hydraulics is the one to watch.

What tip would you give to manufacturers of mobile hydraulic components and systems?

The easiest vehicles to electrify are the smaller vehicles, such as mini-excavators and forklifts. Vehicle OEMs have big ambitions in this area. For example, Volvo has an initiative to electrify their entire fleet of mini-excavators. So, my short-term tip to companies in the mobile hydraulic value chain would be: if you are trying to make more efficient hydraulics to fit into the growing electrified portion of the market, then building out solutions alongside small vehicle electrification initiatives is the best possible opportunity to prove your technology so it is not as risky when larger vehicles begin to adopt it.

Courtesy: Interact Analysis

For details, contact Brianna Jackson on Email: brianna.jackson@interactanalysis.com

Related Stories

Tariffs are reshaping automation supply chains: Blake Griffin

In this interview, Blake Griffin, Research Manager, Interact Analysis, highlights how trade wars, geopolitical tensions and rare-earth restrictions are reshaping global automation industry.

Read more

Can AI be the game changer for Indian manufacturers?

While manpower issues and quality are driving adoption of industrial automation, cost and lack of knowledge are causing hindrances. Artificial intelligence (AI) can be the game changer, writes Rakes..

Read more

Automation to Drive Packaging Machinery Market Surge

Rising labour costs, regulatory pressures, and the growing influence of e-commerce are driving the demand for end-of-line and warehousing packaging machineries. This growth is reshaping packaging st..

Read moreRelated Products

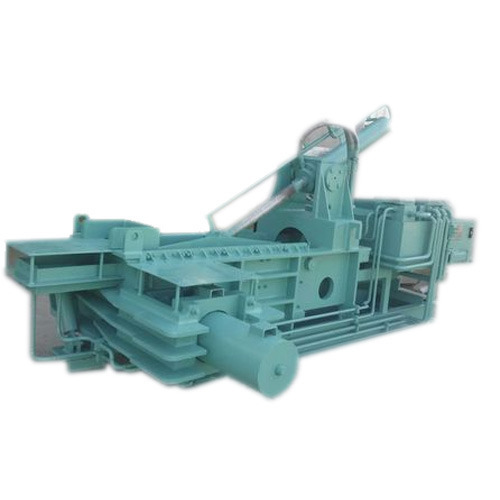

Baling Machine

Mask Hydraulic Machineries provide triple action scrap baling machines. Read more

Manifold Block

Om Shakthi Hydraulics offers a wide range of hydraulic manifold blocks. Read more

Exclusive Hydraulic Fittings

Supreme Engineers is engaged in manufacturing and supplying an exclusive range of hydraulic fittings. Read more