Schedule a Call Back

Turning the tide on emissions: Engineering sustainable materials with simulation

Articles

Articles- May 28,25

- Selection of materials in early design: Embedding sustainability from the earliest stages of product development can reduce redesign and cost overruns.

- Reducing the environmental footprint through lifecycle thinking involves assessing environmental impact from cradle to grave and shifting toward materials with lower carbon impact, recyclability, and non-toxicity.

- Material circularity: Endorsing reuse, recycling, and designing for disassembly to support a circular economy.

- Data-driven decision making: Material Iintelligence can help engineers and designers make informed and more sustainable material choices.

- Industry-specific sustainability goals: Industries are now focusing on applications that deliver on performance, cost, and sustainability – be it lightweighting in automotive or sustainable packaging in FMCG.

- Regulatory compliance/ risk mitigation: Avoiding hazardous substances and ensuring tightening environmental regulations like REACH, RoHS, EPR, etc., is also necessary.

- Lack of awareness: Many engineers are still unaware of the tools and methods to assess the impact of their material decisions on environmental performance.

- Siloed data: Disparate material data across departments means suboptimal, non-collaborative decision-making.

- Low adoption of early sustainability assessment tools: Modern tools allow environmental impact assessments during design stage and avoid sustainability risks later in the product's life cycle. The industry adoption of such tools is still nascent.

- Compromises between cost, performance, and sustainability: Balancing technical and economic feasibility with environmental goals is multifaceted and requires specialized tools.

- Integration issues with current CAD/CAE/PLM workflows: There is a lack of seamless integration, pushing sustainability assessments to later in product development, causing revisions and delays.

- Compliance and traceability: Without a proper traceability mechanism, it is nearly impossible to attribute a product problem to the source of the issue, which may involve materials, product design, or manufacturing.

- Data gaps: In-house materials data is often insufficient for product development. High-quality reference data is crucial to maintain product development timelines and cost targets.

- Execute what-if analyses to gauge the impact of materials, processes, mass, etc.

- Seamlessly integrate with CAD, CAE, and PLM systems.

- Measure environmental footprints from cradle to gate during the design phase itself.

- Deploy modern tools and data that combine technical, economic, and sustainability aspects in materials selection.

- Ensure traceability and consistency through a centralized, unified data and digital thread of materials information.

- Generate and maintain an approved materials list aligned with overall sustainability objectives.

- BoM analyser for energy and CO2 footprint: This enables engineers to evaluate the full bill of materials (BoM) against sustainability criteria like recyclability rate, end-of-life recoverability, presence of hazardous substances, and potential for reuse

- Material substitution & what-if analysis: This allows teams to simulate the environmental and performance impact of replacing virgin or toxic materials with recycled or biodegradable alternatives and materials that enable better end-of-life processing (e.g., easier disassembly)

- Environmental footprint data access that allows engineers to draw on an extensive material database with circularity and environmental impact indicators, and the integration of in-house and reference datasets for full traceability

- Preferred material lists that help standardise environmentally safer and circular materials across the enterprise, reducing variability and increasing compliance with corporate sustainability policies.

- Accurate Multiphysics simulation to improve the fidelity of complex simulations with enhanced data for thermoelectrics, alloys, polymers, and electromagnetics.

- Seamless Integration and direct access to preferred materials lists from CAD/PLM tools will increase design efficiency.

- Digital thread enablement and integration across design and manufacturing workflows ensures that materials decisions are carried forward consistently, thus reducing rework and compliance risks.

- Maintain a centralised repository of materials enriched with sustainability metrics and ensure data traceability through a single source of truth for better materials management.

- Conceptual design to evaluate sustainability indicators right at the start of product ideation and use simulation to test material and process combinations quickly.

- Detailed design to assess BoMs at component and system levels and pre-approved materials lists to ensure alignment with sustainability goals.

- Automate the generation of sustainability reports and track progress toward internal goals and external requirements for reporting and compliance.

Related Stories

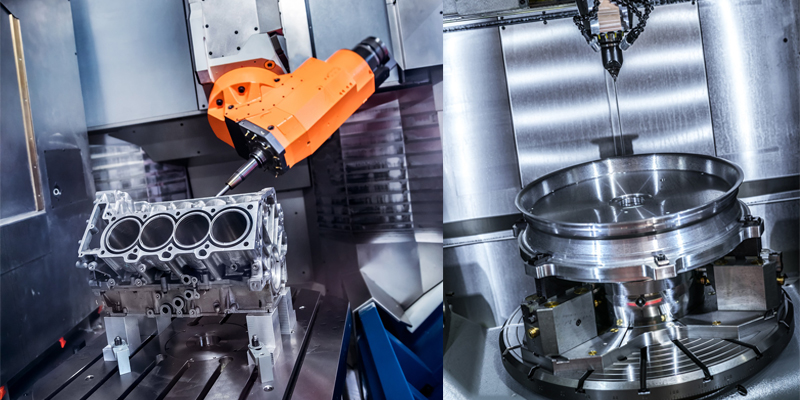

US tariff: Partnerships and innovation to drive Indian machine tools demand

The India machine tools industry is expected to reach $ 3.87 billion by 2030, growing at a CAGR of 7.3 per cent from 2023 to 2030. Amid tariff war, the industry will have to bank on global partnersh..

Read more

Engineering Innovation Driving Industrial Decarbonisation and Energy Security

Industries worldwide face the dual challenge of meeting soaring energy demand while cutting emissions. Engineering innovations such as carbon capture, electrification, smart grids, and hydrogen fuel..

Read more

European machine tool makers see India as strategic partner: Filip Geerts

In this interview with Rakesh Rao, Filip Geerts, Director General, CECIMO, shares his insights into the challenges, opportunities, and outlook for the European and global machine tools sector

Read moreRelated Products

Digital Colony Counter

Rising Sun Enterprises supplies digital colony counter.

Robotic Welding SPM

Primo Automation Systems Pvt. Ltd. manufactures, supplies and exports robotic welding SPM.

Heat Exchanger Scale Removal Compound -hesr-300

Hi There!

Now get regular updates from IPF Magazine on WhatsApp!

Click on link below, message us with a simple hi, and SAVE our number

You will have subscribed to our Industrial News on Whatsapp! Enjoy