Schedule a Call Back

Sustainability practice in corporates has created business growth for Soma Specialities

Interviews

Interviews- Jan 22,24

Related Stories

Teledyne Launches Industrial Image Sensors for Space

These new products complement Teledyne’s ongoing offerings for demanding science and defense missions by providing options for the less rigorous New Space market.

Read more

Can Academia-Industry Ties Power India’s Manufacturing?

India's industrial sector has exhibited tremendous resilience and appetite for growth. However, the academia-industry collaboration will be crucial for India to become a worldwide manufacturing powe..

Read more

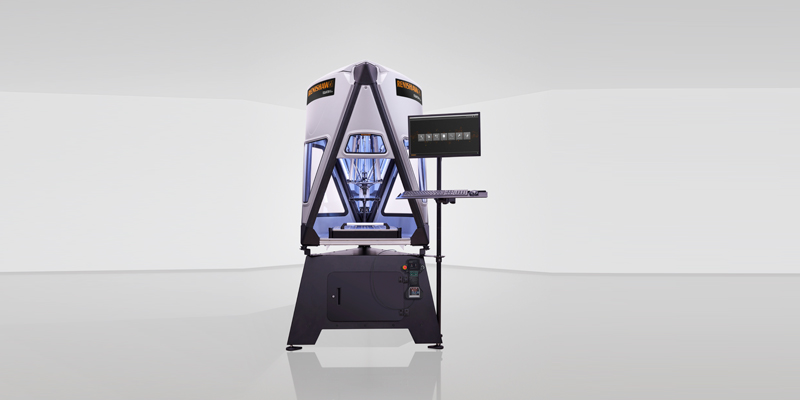

ZASCHE Handling Unveils Smart Handling System

Smart Handling BIG BIN Picking is a modular, vision-enabled system that blends ergonomic manual control with smart semi-automation

Read moreRelated Products

Metal Dust Collector

Fine Fab India offers a wide range of metal dust collector.

Industrial Vacuum Cleaners

Rotamec Engineers offers industrial vacuum cleaners.

PFERD composite brushes

SWIT offers a wide range of PFERD composite brushes