Schedule a Call Back

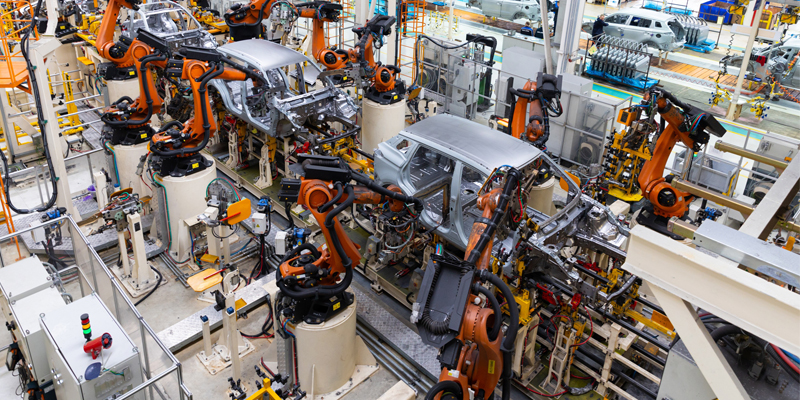

How AI is Revolutionising Manufacturing

Articles

Articles- Jun 26,25

Related Stories

Smart Factories in India: Reality or Distant Dream?

As India moves toward its goal of becoming a $7 trillion economy by 2030, embracing smart manufacturing technologies will be crucial for achieving this ambitious target, writes Rakesh Rao. But, is t..

Read more

Predictive Maintenance: How AI is Reducing Unplanned Downtime in Manufacturing

Predictive maintenance is no longer a luxury—it’s a necessity. By integrating AI with IoT, digital twins, and edge computing, manufacturers can proactively address equipment issues, maximise upt..

Read more

Driving Efficiency: Schmalz Gripping Systems for India's Manufacturing Future

As the market demands speed, agility, and reliability, Schmalz gripping systems are enabling the next generation automation of Indian manufacturing sector.

Read moreRelated Products

Digital Colony Counter

Rising Sun Enterprises supplies digital colony counter.

Robotic Welding SPM

Primo Automation Systems Pvt. Ltd. manufactures, supplies and exports robotic welding SPM.

Heat Exchanger Scale Removal Compound -hesr-300

Hi There!

Now get regular updates from IPF Magazine on WhatsApp!

Click on link below, message us with a simple hi, and SAVE our number

You will have subscribed to our Industrial News on Whatsapp! Enjoy