Schedule a Call Back

SCHUNK develops miniature clamping module for metal cutting industry

Industry News

Industry News- Sep 29,21

Related Stories

Hannover Messe 2025 presents battery cell and pack production for EVs

Electric mobility is seen as a key technology for long-term emission reductions – and consequently for a more sustainable future.

Read more

Enhancing metal cutting with IoT connectivity

IoT-enabled metal-cutting machines can dynamically adjust spindle speeds, coolant flow rates, and feed rates based on real-time feedback. This level of automation minimises human error and enhances ..

Read more

Simple Finger Change During an Ongoing Process

With the new jaw quick-change system BSWS-R, SCHUNK enables automated finger changes during an ongoing process. The cleverly designed system consists of just a few components and is compatible with ..

Read moreRelated Products

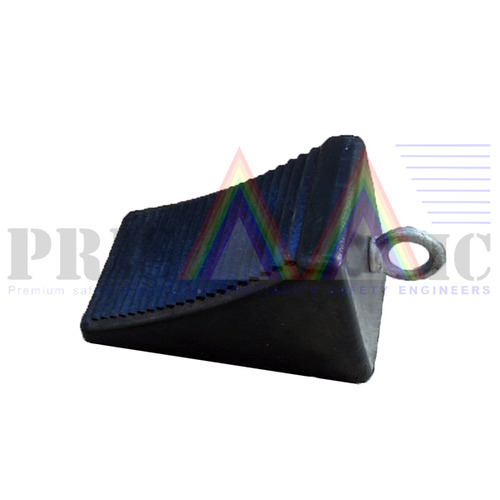

Wheel Clamp

Speciality Safety Engineers offers a wide range of wheel clamp.

Impact Wrench

Hardware & Pneumatics offers a wide range of impact wrench.

Quick Release Couplers - Straight Through

Vijay Air Control offers a wide range of quick release couplers - straight

through.