Schedule a Call Back

Schaeffler's centrifugal disc ball bearing bags innovation award

Industry News

Industry News- May 24,22

They literally move the world, as no powertrain can do without bearings ? be it electric cars, hybrid vehicles or internal combustion engines. Schaeffler has now developed a special high-performance ball bearing with an integrated centrifugal disc. This disc helps lower CO2 emissions in vehicles with combustion engine and hybrid powertrains. Electric cars, on the other hand, benefit from the fact that they can drive further on a single charge. The bearing weighs just 300 grams and is between five and ten centimeters in diameter, depending on the application. “Innovative strength is a key factor safeguarding Schaeffler's corporate success and automotive business. Our new ball bearing will make drives even more efficient and further increase the appeal of electric mobility for everyday use,” said Matthias Zink, CEO Automotive Technologies at Schaeffler AG.

The first automotive manufacturers have been using the new ball bearing in production hybrid and double-clutch transmissions since 2021, and the automotive and industrial supplier is collaborating with other manufacturers in development projects moving forward to a volume production launch. The company is likewise transferring the patent-pending technology to ever new application areas in its bearing business, including dedicated electric vehicles. Schaeffler’s innovative bearing received recognition recently when it won the 2022 German Innovation Award in the large-scale enterprise category.

The best of two designs

Ball bearings are either open on the sides ? known as open bearings ? or have seals made from special rubber. These sealed bearing units keep contamination away from the balls and raceways of the bearing rings. This translates into less wear and, thus, a longer service life. The drawback, however, is the higher level of friction in the bearing, which corresponds to valuable energy being lost. In open-style bearings, although this friction is reduced, the bearing units break down more quickly due to the lack of protection from contamination. A real dilemma.

With the high-performance ball bearing with integrated centrifugal disc, Schaeffler has developed a truly unique bearing that combines the benefits of an open bearing with those of a sealed one. As such, significantly less energy is lost in the bearing in the form of friction. “Less friction means that drive energy is used more efficiently. This, in turn, lowers emissions and improves the range of electric vehicles,” said Dr Dieter Eireiner, Head of the Bearing Business Division at Schaeffler.

What really makes the new bearing stand out is that the rubber seals that are normally attached firmly to the outer sides of the bearing are replaced with a specially designed centrifugal disc integrated in the inner ring. This disc keeps contamination out ? similar to a sealed bearing. Since the disc rotates freely, however, the bearing generates about 80 percent less friction than with conventional seals. The result is a CO2 reduction of up to 0.3 grams per kilometer per vehicle. Reducing losses of up to 30 watts per bearing can also improve the range of electric vehicles by up to one percent. “Efficient bearing solutions play a key role in sustainable mobility. With our new bearing, Schaeffler shows that small changes can make a big difference,” said Dr Eireiner.

The centrifugal disc bearing also lasts considerably longer. Compared to an open bearing, the service life increases by a factor of up to ten, whereas the unit lasts twice as long as conventional sealed ball bearings. This, then, means that bearing and transmission assemblies can be downsized in the future, thereby conserving material and weight.

Ball bearings for greater efficiency in electric drives

Schaeffler has been developing and manufacturing needle roller bearings for over 70 years now. In 2001, the company acquired FAG Kugelfischer Georg Schäfer AG in Schweinfurt, Germany thereby significantly expanding its rolling bearing portfolio. Bearings are indispensable for the automotive industry as well as in mechanical engineering and transmission manufacturing. Even dedicated electric vehicles cannot do without them. In electric cars, although one forward gear is usually enough to whiz away, they also use what is known as a reduction gear to reduce the speed of the electric motor by a fixed factor, thereby making it compatible with both low and high speeds.

As more and more electric motors reach speeds of up to 20,000 rpm, higher demands are being placed on the design, material, and coating of transmissions as well as the bearings they house. “The shift toward electric powertrains is driving innovation in bearing development,” said Dr Eireiner. To this end, the company has combined its comprehensive system know-how when it comes to bearing technology and electrified drive systems. It is on this basis that Schaeffler also develops bearings that prevent e.g. current-induced damage, particularly in electric drives running at 800 volts or with silicon carbide semiconductors as used in power electronics.

2022 German Innovation Award

Schaeffler was chosen to receive the 2022 German Innovation Award in the large-scale enterprise category for its high-performance ball bearing with integrated centrifugal disc. The award was presented on April 29, 2022 in Munich. It was accepted by Uwe Wagner, CTO at Schaeffler AG, and Dr. Dieter Eireiner, Head of the Bearing Business Division at Schaeffler as presented by Christina Raab, CEO of Accenture.

As a leading global supplier to the automotive and industrial sectors, the Schaeffler Group has been driving forward ground-breaking inventions and developments in the fields of motion and mobility for over 75 years. With innovative technologies, products, and services for electric mobility, CO?-efficient drives, Industry 4.0, digitalization, and renewable energies, the company is a reliable partner for making motion and mobility more efficient, intelligent, and sustainable. The technology company manufactures high-precision components and systems for powertrain and chassis applications as well as rolling and plain bearing solutions for a large number of industrial applications. The Schaeffler Group generated sales of approximately Euro 13.9 billion in 2021. With more than 1,800 patent applications in 2021, Schaeffler is Germany’s third most innovative company according to the DPMA (German Patent and Trademark Office).

Schaeffler has been present in India for about 60 years. With 3 well known product brands LuK, INA and FAG, 4 manufacturing plants and 8 sales offices, Schaeffler has a significant presence in India. Schaeffler is among the largest Industrial and Automotive supplier with sales of Rs 55.6 billion in 2021 and around 2,922 employees. The manufacturing plants in Maneja and Savli (Vadodara), produce a vast range of ball bearings, cylindrical roller bearings, spherical roller bearings and wheel bearings that are sold under the brand name of FAG. The plant at Talegaon near Pune, manufactures engine and powertrain components for front accessory drive system, chain drive systems, valve train, gear shift systems and a range of needle roller bearings and elements, under the brand INA. The fourth manufacturing location is based out of Hosur, producing a wide range of clutches and hydraulic clutch release systems for passenger cars, light commercial vehicles, heavy commercial vehicles and tractors sold under the brand of LuK.

Related Stories

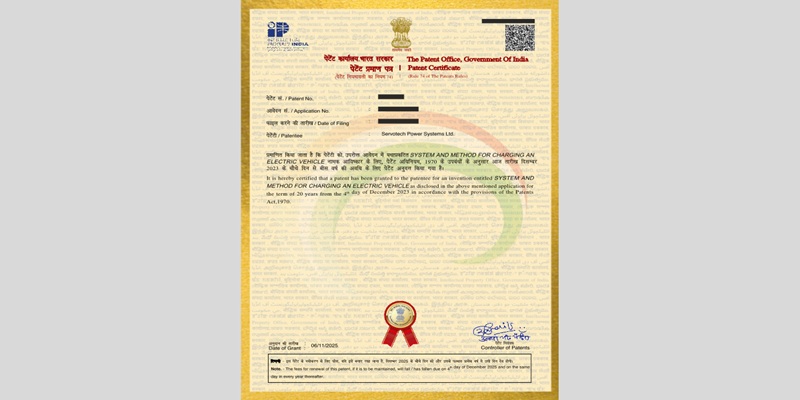

Servotech Secures Patent for Breakthrough EV Charging Compatibility Technology

Servotech’s patented device acts as a smart converter that, when connected to a CCS2 charger, allows GBT vehicles to charge safely, quickly, and efficiently.

Read more

iRasus and Jouletap Strengthen EV Battery Reliability Through Preksha Platform

The partnership has led to big improvements in operations thanks to iRasus' flagship Preksha platform.

Read more

HANNOVER MESSE Launches New Defence Production Area in Hall 26

This new platform fosters direct connections between suppliers and users, facilitating targeted dialog on industrial production for security-critical applications.

Read moreRelated Products

Auto Wheel Hub Bearings

Kasuma Auto Engg Pvt Ltd offers a comprehensive range of Auto Wheel Hub Bearings.

Gear Lever Kits

B S Industry offers a wide range of gear lever kits.

Automotive Gear

Matrix Precision Engineering offering a personalized array of automotive gear.