Schedule a Call Back

Raghu Vamsi moves beyond the manufacturer-partner role: Preeti Vamsi

Articles

Articles- Jan 26,26

Raghu Vamsi Aerospace Group is an Indian aerospace and defence manufacturer with multi-location capabilities across machining, systems and integration. It is shifting from precision manufacturing to full-system design, deep-tech investments, and an expanded role in India’s aerospace and defence ecosystem, shares Preeti Vamsi, CEO & Executive Director, Raghu Vamsi Aerospace Group.

Kindly brief us about Raghu Vamsi Aerospace Group (in terms of its businesses, manufacturing facilities, end-user industries served, etc)

Raghu Vamsi Aerospace Group commenced its operations in?2004, with dominance on precision machining and manufacturing. We had established our credibility over the years by supplying sophisticated, high precision components to global and Indian aerospace and defence customers. That phase of our journey we called execution discipline to quality, repeatability and delivery reliability because without?that nothing else is sustainable in this business.

Today the Group is spread across several manufacturing locations (10?sites) offering capability across precision machining, sheet metal, composites, special processes, electronics and systems-level integration. We cater to all end user industries like?aerospace, defence, space, oil and gas, power, industrial systems etc.

What makes Raghu?Vamsi different today is the fact that we are not just a manufacturer-partner anymore. We have deliberately added capability in design,?system integration, propulsion and autonomy to enable us to be end-to-end responsible for complex programmes rather than engaging at the part or component level.

The launch of your new DeepTech campus and the ARROBOT platform marks a shift from component manufacturing to full system design and integration. How does this expansion reshape Raghu Vamsi Aerospace Group’s long-term positioning within India’s defence ecosystem?

For me our deep tech campus and ARROBOT platform signifies a deliberate?pivot in how we view ourselves in the defence ecosystem of India. Making components, while crucial, limits the amount of responsibility and ownership an Indian company can?assume. True self-sufficiency?means being able to design, construct, test, operate, and maintain systems for their entire life span.

This does not mean abandoning manufacturing excellence, but it means building on it. Our Citadel campus allows us to bring design, integration, and testing closer to production, which fundamentally changes how quickly and responsibly systems can be developed and matured. Over the long term, this positions Raghu Vamsi as a contributor to capability creation, not just capacity addition.

With over Rs 1 billion committed to new infrastructure and technology development, which capabilities—UAV platforms, propulsion systems, or autonomous technologies—will drive the next phase of growth for the Group?

We invest across more than one technology vertical. The UAS industry's next expansion phase will involve the convergence of three areas including unmanned platforms, propulsion, and?autonomy.

Unmanned systems reduce operational risk and increase flexibility. Propulsion defines independence. Even if platforms could be constructed anywhere, they?would be stuck simply because their propulsions were already controlled. Autonomy and intelligent systems glue these all together, allowing?for scalable and flexible roll-out.

But there’s no need to pick one versus the other, we are deepening capability across all three because next-generation defence capabilities will require integrated capacity and not siloed competence.

India’s defence manufacturing landscape is moving rapidly towards unmanned, autonomous and AI-enabled systems. What structural changes are you seeing in how defence forces define requirements and evaluate indigenous technologies today?

One shift that is clear is that requirements are becoming more outcomes focused. Rather than purely?concentrating on platform specifications, the focus is more and more turning to operational systems that are in use, supported, and changing.

One significant change is that today, Defence forces are much more willing?to talk to industry during development phase and not only in relation to the trials. It’s how?we connect what our engineers do with the way it works in real life. While this shift remains uneven, it’s an encouraging sign in a VUCA world where adaptability matters?as much as performance.

As India transitions from an importer to a designer and exporter of defence technologies, what are the most critical gaps that still need to be addressed across design maturity, testing infrastructure and certification frameworks?

India has come a long way in the capability to design and depth of manufacturing, but gaps still exist in the?crucial middle layer consisting of testing, certification and sustained validation. There are many examples?of technologies that work well in development but encounter challenges in scaling production and deployment at scale due to issues related to capacity, long timelines for approval or lack of coupling between development, trials, and scale up across the programs today.

The new campus integrates design, manufacturing, assembly and testing under one roof. How important is this design-to-deployment model for reducing development cycles and achieving scale in next-generation defence systems?

When you?have many organisations working on a project, the design and manufacturing is split, integration and test is a mess and this the defence programs stagnate. Decisions are deferred; it becomes unclear who owns what and time frames stretch?on. We?reduce hand-offs and shorten learning cycles by pulling these functions together. Problems are recognised earlier, and?feedback loops shorten; people know what to respond to rather than waiting for something top-down. This is way of working is a necessity for speed, accountability and?scale.

From propulsion systems to swarm intelligence and autonomous ground platforms, defence technologies are becoming increasingly multidisciplinary. How should Indian industry and academia collaborate to keep pace with the complexity of future warfare systems?

Cooperation?should not be limited only to the results of research, but also to its applicative dimension. While academia is good in algorithms, materials science and foundational research, the industry can provide manufacturability, reliability, cost,?and scale. This partnership works when both sides talk early and?straight. Research must be engineered from the outset with?future production and deployment in mind, and industry must spend time cultivating these relationships rather than seeing academia as a downstream resource.

Looking ahead five to ten years, how do you assess the outlook for India’s aerospace and defence sector, particularly in terms of exports, private-sector participation and India’s role in global supply chains?

I am cautiously optimistic. Private-sector involvement will expand, not replace incumbent players, but?complement them. India will no longer participate in global supply chains only as a supplier of components but will also be responsible for systems, specifically in unmanned and autonomous domains. “Success will be when Indian companies are no?longer referred to as emerging, but presumed competent.”

Related Stories

Raghu Vamsi moves beyond the manufacturer-partner role: Preeti Vamsi

In this interview, Preeti Vamsi, CEO & Executive Director, Raghu Vamsi Aerospace Group shares its shift from precision manufacturing to full-system design, deep-tech investments, and its evolving ro..

Read more

India serves as a strategic pillar for Silmax’s Asian expansion: Dr Fumagalli

In this interview with Rakesh Rao, Dr Dario Maria Fumagalli, President & CEO, Silmax, elaborates on the growth potential of India’s machine tools industry and the company’s long-term commitment ..

Read more

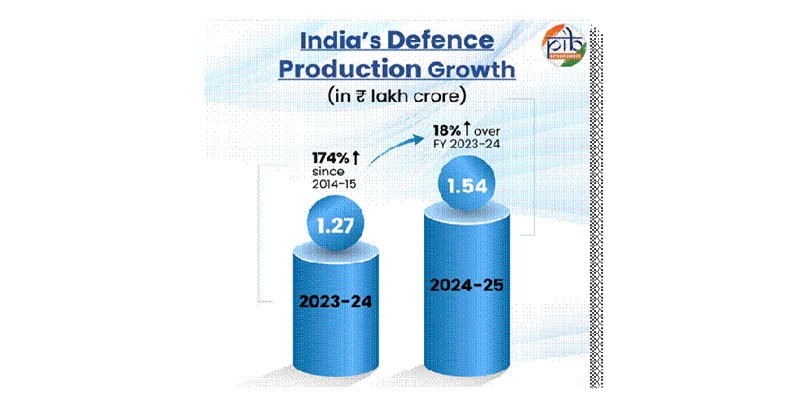

India’s Defence Production Hits Rs 1.27 Trillion, Driven by Reforms

Record output reflects decade of policy reforms, rising exports and strong domestic industry.

Read moreRelated Products

Integrated Electric Gripper S Series

IBK Engineers Pvt Ltd offers a wide range of integrated electric gripper S series.

Geared Electric Motors

Delco Fans Pvt Ltd offers single phase capacitor run and three

phase geared Instrument motors, totally enclosed face/foot mounted.

“Kusam-Keco” Partial Discharge Acoustic Imager - Model - Km-pdai

‘Kusam-Meco’ has introduced a new “Partial Discharge Acoustic Imager Model KM-PDAI.