Schedule a Call Back

Japan’s Fuji Electric opens new facility in India for automation solutions

Industry News

Industry News- Mar 16,23

Related Stories

ABB India Upgrades Peenya Plant, Adds 25% VSD Capacity

The new line features a combination of advanced robotics and digital production monitoring technology, handling production of large batches with speed and precision and providing real-time visibilit..

Read more

ECMS to Boost India’s Local Electronics Value Addition to 40%

The scheme has attracted record investment proposals worth Rs 1.15 trillion, more than double the initial target of Rs 590 billion.

Read more

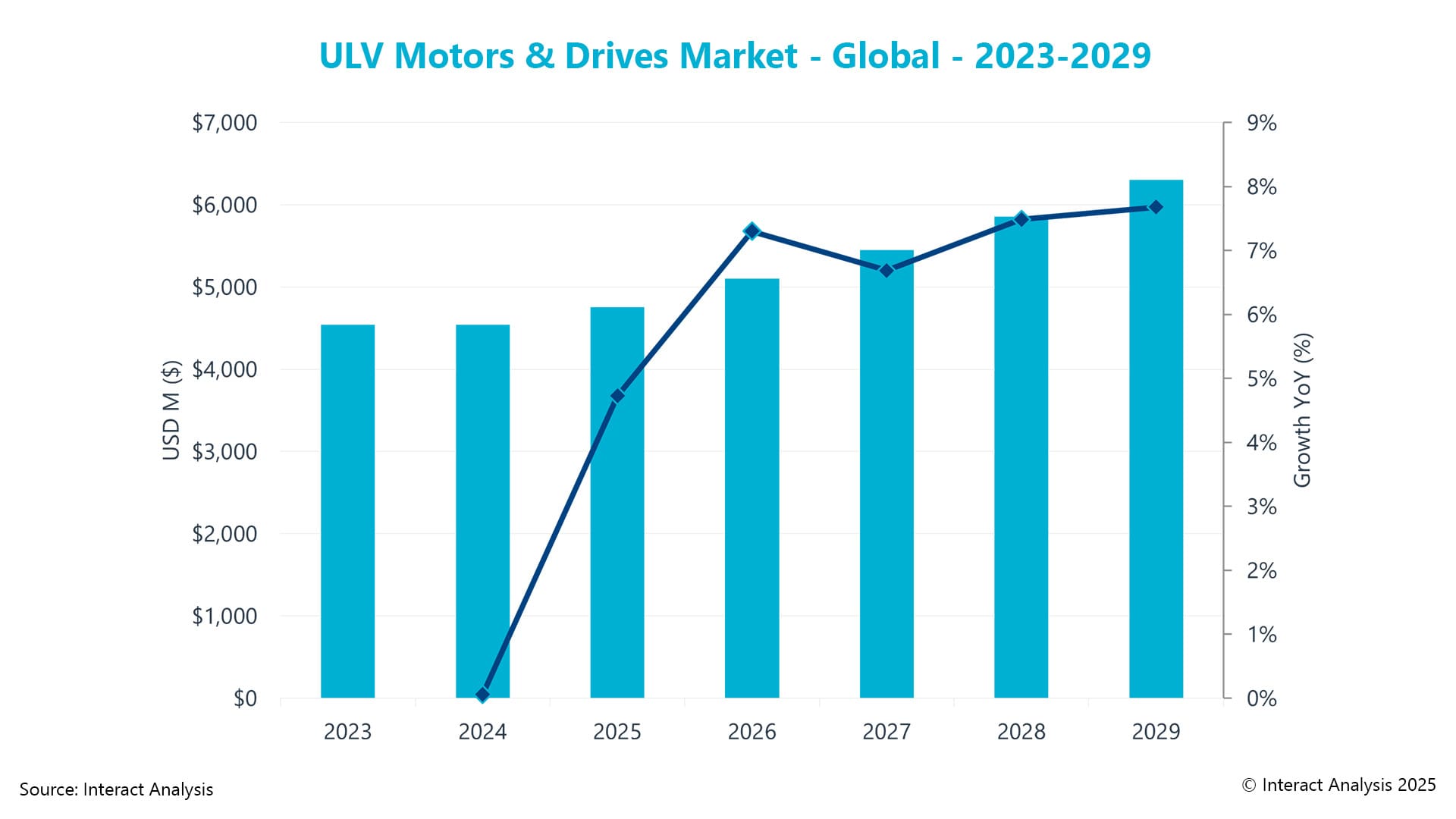

Ultra-low voltage motors and drives sector rebound in 2025: Interact Analysis

After growing at 0.1 per cent in 2024, the ultra-low voltage (ULV) motors and drives market is set for recovery in 2025, driven by mobile robotics and renewed industrial automation demand.

Read moreRelated Products

Digital Colony Counter

Rising Sun Enterprises supplies digital colony counter.

Robotic Welding SPM

Primo Automation Systems Pvt. Ltd. manufactures, supplies and exports robotic welding SPM.

Heat Exchanger Scale Removal Compound -hesr-300

Hi There!

Now get regular updates from IPF Magazine on WhatsApp!

Click on link below, message us with a simple hi, and SAVE our number

You will have subscribed to our Industrial News on Whatsapp! Enjoy