Schedule a Call Back

How to use sensors to monitor water pressure of boiler

Articles

Articles- Jun 24,22

Related Stories

Is your facility ready to handle the energy demands of full automation?

As warehouses scale AI-driven automation, energy demand is emerging as a critical constraint alongside productivity gains. Strategic power planning is now essential, writes Emily Newton.

Read more

How is AI shaping the future of cement milling?

AI is transforming cement milling by enabling dynamic, data-driven control that improves energy efficiency, stabilises throughput and enhances asset reliability. By leveraging real-time data, predic..

Read more

4 Low-VOC Industrial Paints That Deliver High Performance in Tough Environments

Volatile organic compounds (VOCs) - contaminating air and water - can affect health. In this article, Emily Newton explores four high-performance, low-VOC industrial paint options that reduce harmfu..

Read moreRelated Products

Biomass and Coal Fired Spreader Stoker Boiler

Sitson India Ltd offers a wide range of biomass and coal

fired spreader stoker boiler

Coil Type Boilers - VRS Series

Maxima Boilers Private Limited offers a wide range of coil type boilers - VRS Series

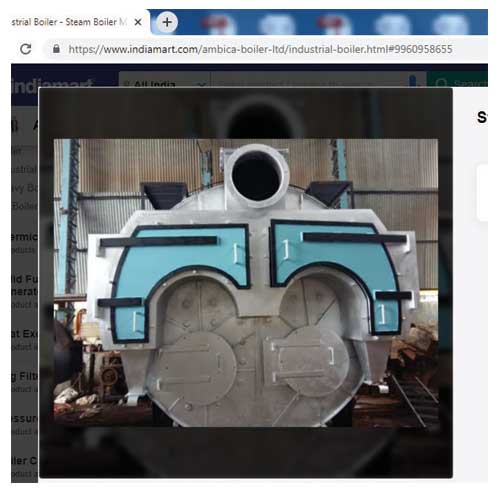

Steam Boiler

Ambica Boiler offers a wide range of steam boiler.