Schedule a Call Back

Focussing on changes in tube forming technology

Industry News

Industry News- Nov 23,16

November 2016 – Topics such as digital transformation and industry 4.0 are more relevant than ever. The 12th Innovation Days of the mechanical engineer transfluid were all about progress, digitalisation and new challenges for this industry. Experts and specialist audience have already met for the 12th time under the motto “Time for change! Which possibilities does the tube forming technology offer?†in order to discuss potentials for optimisation of processes and methods and to explore the opportunities of current automation solutions. Practical presentations of experts provided a fascinating input and initiated the exchange of experiences on the latest technologies and trends.

“What we also noticed during our Innovation Days is that the process monitoring plays an increasingly central role, i.e. data and evaluation on demand. Of course, cost efficiency is and remains also a trend. We solve this issue, for example, by new forming technologies with very low tooling costs. Integrated systems, such as a transfer bending head, which we also use in our proven transfer systems, significantly improve the processesâ€Â, thus Stefanie Flaeper, managing director at transfluid.

A presentation on new control concepts, which allow the central management of all production processes, among others, offered versatile insight into the industry 4.0. Key aspects of this are particularly the integration and the exchange of data from engineering, administration and production, supplier chain and logistics. Another topic was the efficient steam cleaning of components in the automatic process. The main focus was particularly on the low water and detergent consumption as well as the accessibility of places difficult to access. Another speaker pointed out the possibilities of leak tests of components with short cycle times.

The contribution of transfluid on the focus topic “Time for change! Which possibilities does the tube forming technology offer?†provided fascinating insights around borderline forming, new tooling concepts as well as cost-optimised forming technology. The host of the Innovation Days presented the innovations of proven machine concepts as well as the advantages of partially or fully electrical plant concepts in a second presentation. Software solutions, control systems and effective equipment variants also showed new possibilities, as well as a more environmentally-friendly and more energy-efficient plant engineering.

During the transfluid tour of the plant, the guests of the Innovation Days could experience effective practical solutions. In retrospect, managing director Stefanie Flaeper was pleased with the intensive discussions and the positive reactions of the participants: “I am always impressed again and again about how much the exchange between the participants of the Innovation Days brings benefit to us all. It provides valuable inputs, not only from the speakers, but also from the guests. This also gives rise to promising networks in the course of the conversations. That way, we can look at and further develop the topic of tube machining together from new perspectives. For us as host, this is again and again an amazing experience, which we definitively would like to repeat in the next year.â€Â

Related Stories

Super Screws and Mitsuchi Corporation to manufacture cold forged parts in India

The new venture will set up a manufacturing plant in India to produce and distribute high-quality cold forged parts, catering to both the Indian market and global exports.

Read moreASMI submachine gun from Hyderabad's Lokesh Machines Ltd. used for army service

The National Security Guard (NSG) and the Assam Rifles have received pilot lots of the ASMI and have expressed interest in further deployment, while the Border Security Force (BSF) has placed a pilo..

Read moreEicher rolls out 50,000th bus from Baggad plant

The 50,000th vehicle was an Eicher Skyline Pro E electric bus.

Read moreRelated Products

Welding Automation

Drupe Engineering Private Limited is offering a wide range of welding automation.

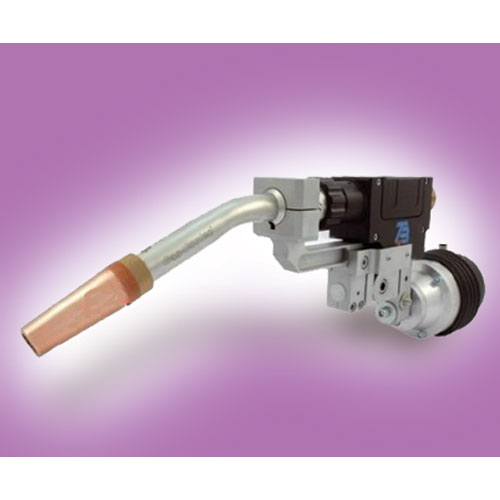

Robo Mig Tbi Robot Welding Torches

Mehta Sanghvi

& Company manufactures Robo MIG TBI robot welding torches.

Heavy Duty Goliath Crane

Ganesh Engineering Co manufactures and supplies a broad array of heavy-duty goliath crane.