Schedule a Call Back

Engine coolant is liquid engineering at work

Industry News

Industry News- Jul 09,21

There is nothing sophisticated about coolant, just mix a bit of antifreeze with some water and it’s good to go right? Well, the answer to that depends entirely on how long you expect your engine to last and how much you want to spend repairing it because coolant does a lot more than simply move heat from the engine to the radiator. To those who design cooling systems the coolant they depend on is a product of liquid engineering and it’s anything but unsophisticated.

In addition to protecting an engine from heat and cold, a properly formulated coolant serves as a carrier for additives such as pH stabilizers, anti-foaming agents, and protection agents for rubber and plastic components. It also contains additives that inhibit corrosion within the heat transfer system that typically includes components made of copper, brass, steel, cast iron, aluminium and solder. Without that protection, corrosion can block the narrow spaces in a radiator, which can lead to overheating of the coolant causing damage to water pumps, oil coolers, cylinder heads and gaskets.

A less obvious feature of coolant is protection against cavitation and cylinder pitting, particularly in wet-cylinder diesel engines where the sleeve that contains the piston comes into direct contact with the coolant. While this design allows more efficient heat transfer, it also transfers a lot of vibration and movement from the pistons to the cylinder sleeve and through the sleeve to the coolant which can cause cavitation.

Unless the coolant is formulated with additives to prevent cavitation the tiny bubbles created can lead to pitting of the sleeves and premature failure. While this is less of a problem with parent bore engines where the cylinder is part of the block, and dry-sleeve engines where the liner is inserted into the block but does not contact the coolant, cavitation and corrosion still can occur and need to be protected against.

Because it performs so many critical functions, proper coolant selection and maintenance can have a significant impact on the total cost of ownership (TCO) of a diesel engine. Home-brew mixtures are seldom a good option for a number of reasons including unknown impurities and mineral content of the water and the exact amount and type of additives in the antifreeze.

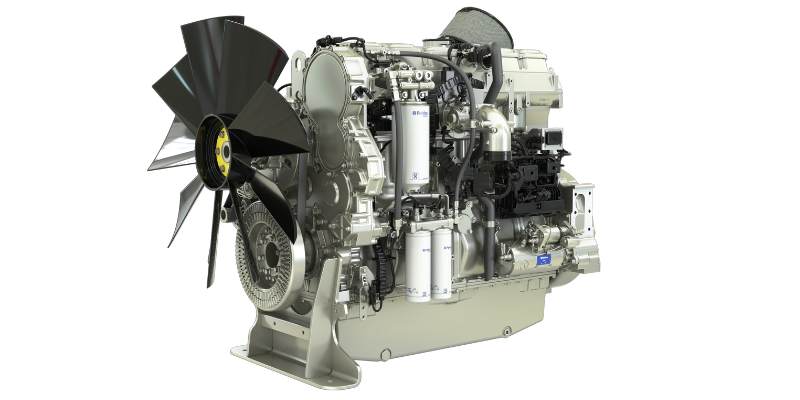

Most engine manufacturers

offer coolants specifically formulated for their products. Perkins, for

example, offers a Long Life or Extended Life Coolant (LLC/ELC). Perkins®

Extended Life Coolant provides optimum engine protection as well as reduced

maintenance requirements over the life of the coolant.

Coolant management

If your engine uses a conventional, commercially available heavy-duty or fully formulated coolant, the corrosion inhibitors are used up over time. Thus, the coolant requires testing every six months, or every oil change, to determine if corrosion additive needs to be added. Testing can be easy to overlook and is often difficult to do when engines are in the field.

Coolant testing typically involves a trip to the local service centre, but test strips are available depending on the corrosion additives being used. Using the wrong test strip, or one that has exceeded its shelf life, could result in incorrect results and improper dosing. If additives need to be replenished, it’s important that only a product meeting the manufacturer’s specifications is used.

If your engine uses Perkins ELC or a similar product, the main requirement is to make sure that the system is properly filled and coolant is changed at the correct period stated by the supplier. For Perkins ELC the change interval is three-years or 6,000 working hours. It is sold in a pre-diluted mixture using mineral-free distilled water to allow the cooling system to be topped-up as necessary straight from the container. When the coolant needs to be changed the system can be flushed with clean water since no additional cleaning agents are required.

Regardless of which type of coolant is used, the level needs to be checked often and topped-up when necessary.

What’s the difference?

Again, using Perkins ELC as an example, it uses an advanced formula with organic additive corrosion inhibitors. Instead of nitrates, silicates, phosphates, borates and amines, Perkins ELC contains mono and dibasic organic acid salts that provide maximum protection for the metal alloys found in most heat transfer systems. In addition, some nitrites and molybdates are added to help protect iron components and reduce steel corrosion and pitting effects.

The Perkins ELC formulation practically eliminates hard water deposits and extends water pump seal life. Removing phosphates and silicates helps prevent scale formation that can reduce heat transfer and encourage corrosion. Moreover, the additives that are used deplete very slowly allowing nitrite levels to be maintained up to 20 times longer than conventional coolants.

The bottom line

Both types of coolant will protect an engine, but one requires testing and periodic maintenance of additive levels and the other doesn’t. An extended life coolant like Perkins ELC also reduces disposal volume by up to 50 percent as well as the related costs, which in an era of increasingly stringent environment regulations can be substantial.

While it’s important to follow an engine manufacturer’s recommendations, Perkins ELC and similar extended life coolants that meet or exceed the ASTM D6210 standard for heavy duty, low silicate antifreeze/ coolants, and ASTM D3306 for light duty and automotive applications are generally compatible with most OEM diesel, gasoline and natural gas engines. That means only one coolant needs to be stocked for an entire fleet, saving additional time and money.

Extended life coolants are excellent examples of what can be achieved with today’s liquid engineering technology. In the specific case of Perkins ELC, more than 20 years of extensive testing and commercial experience has provided customers with a robust level of protection of cooling system components, gaskets, seals and hoses when properly used.

(About the author: Andy Miller works as a Service Training Manager at Perkins.)

Related Stories

Perkins unveils overhaul kits that provide low-cost options to restore engines

To support customers, Perkins has introduced four new overhaul kits for six-cylinder Perkins® 2000 Series engines that provide budget-friendly alternatives to replace and restore engines to like-ne..

Read more

Perkins announces 2806FA-E18TAG CPCBIV+ certified engines for India

The 2806FA platform provides excellent cold load acceptance and meets ISO 8528-5 class G2 performance.

Read more

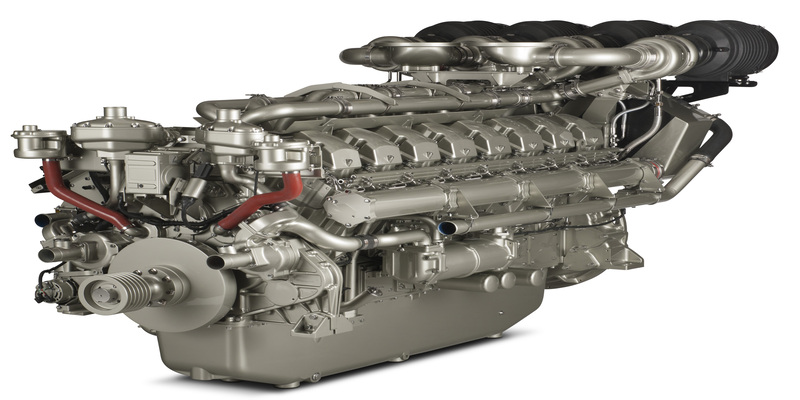

Increased electric power generation solutions demand rises Perkins® 4000 series sales

India is now the second largest consumer of Perkins® 4000 Series engines in the world, due to the rapid rise in standby and prime electric power generation solutions for data centres and the growin..

Read moreRelated Products

Engine Wash System

K R Equipments Pvt Ltd offers a wide range of engine wash system.

Portable Engine Operated Actuators

Indaai Technologies Pvt Ltd offers a wide range of portable engine operated actuators.

Carr Lane Hoist Ring

IBK Engineers Pvt Ltd offers a wide range of Carr lane hoist ring.