Schedule a Call Back

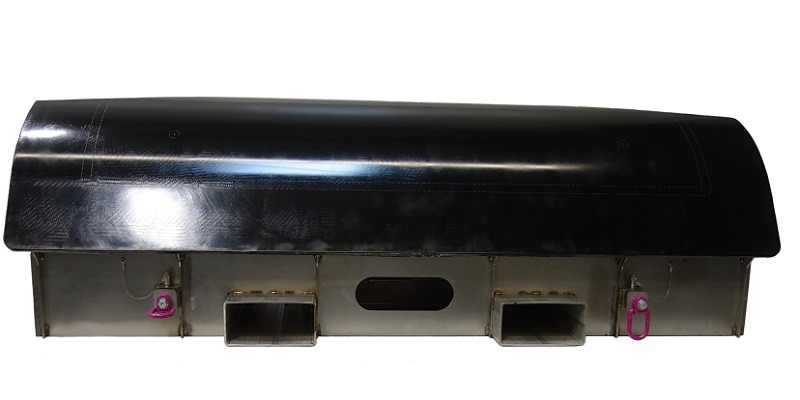

Decision SA and Carboman launch direct mould tooling technology for aerospace

Industry News

Industry News- Mar 10,21

Related Stories

Indian Machine Tools Industry Gains Amid Shifting Global Dynamics

India’s machine tools industry is attracting strong global investment, driven by rising domestic demand, precision manufacturing growth and supply-chain realignments, even as global markets slow. ..

Read more

India’s demand for high-precision machine tools is rising: K Balasubramaniam

In this interaction with Rakesh Rao, K Balasubramaniam, Founder, Tsugami Precision India, discusses the evolving machine tools landscape and the company’s role in shaping India’s manufacturing t..

Read more

India’s Top 100 Engineering Companies 2025 by Smart Manufacturing & Enterprises

FY25 unfolded against a challenging external setting. Despite the global headwinds, India posted real GDP growth of 6.5 per cent in FY2024–25. In this edition, Smart Manufacturing & Enterprises (S..

Read moreRelated Products

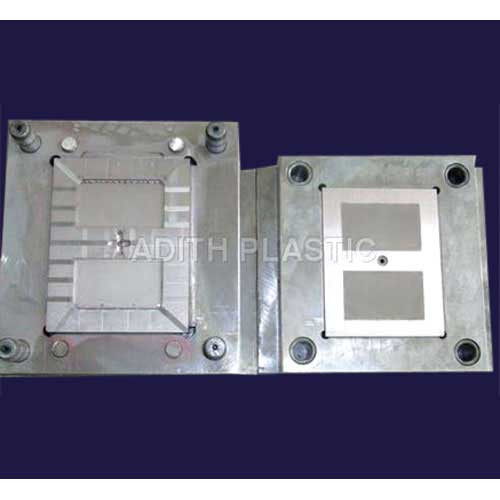

Industrial Moulds

Adith Plastic offers moulds for industrial electronic parts.

Industrial Plastic Moulding Dies

Adith Plastic offers a wide range of industrial plastic moulding dies.

Component Moulds

Innovative Moulds & Dies offers a wide range of plastic component moulds. Read more