Schedule a Call Back

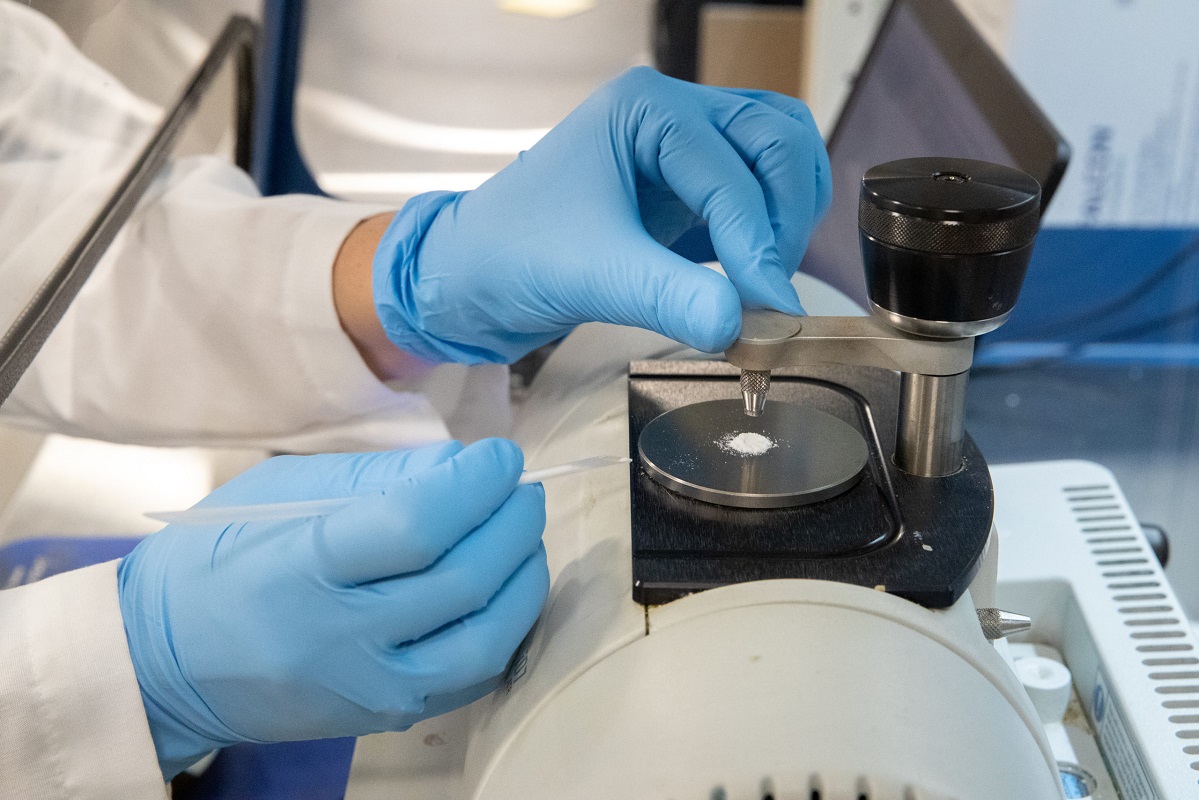

CDSCO shuts down 36% of drug manufacturing units for failing quality standards

Industry News

Industry News- Jun 29,24

Related Stories

Budget 2026 sharpens focus on manufacturing scale-up across strategic sectors

Union Budget 2026–27 advances manufacturing-led growth with sectoral schemes, higher outlays and supply-chain reforms.

Read more

Budget Expectation: Why Materials, Data and Governance Will Shape Manufacturing

India’s manufacturing growth hinges on digitalisation, material self-reliance, and policy clarity to strengthen resilience and global competitiveness, says S Sunil Kumar, Country President, Henkel..

Read more

Gandhi Automations Strengthens Cold Chain with Storage Doors

Discover how Gandhi Automations Pvt Ltd, India’s No. 1 entrance automation and loading bay equipment company, delivers advanced cold storage doors for optimal temperature management

Read moreRelated Products

Programmable Controllers - Pcd-33a Series

Pro-Med Instruments (P) Ltd offers a wide range of programmable controllers - PCD-33A Series.

Gasket Graphite Powder

Arihant Packing & Gasket Company offers a wide range of gasket graphite powder.

Asahi Kasei expands 3D printing filament sales in North America

Asahi Kasei, a leading resin and compounding technology provider, has initiated the sales of 3D printing (3DP) filaments in North America through Asahi Kasei Plastics North America (APNA). The soft la Read more