Schedule a Call Back

Bosch Rexroth’s Smart Flex Effector makes robots more sensitive

Industry News

Industry News- Apr 28,22

The Smart Flex Effector - a new, sensor-based compensation module from Bosch Rexroth - gives robots and Cartesian linear systems human-like sensitivity and thus offers new opportunities for factory automation. Processes which are difficult to manage can now be automated, optimized and monitored through simple retrofitting. Thanks to a kinematics system that works independently in six degrees of freedom, the tactile all-rounder with sensitive touch precisely records the position of the work piece and passes the information to the robot control unit for active compensation purposes. Typical applications are joining processes with minimal tolerances, complex assembly work or difficult handling tasks. Errors and rejects are minimised and teaching and commissioning can be carried out more easily and quickly.

The Smart Flex Effector is designed for handling loads of up to 6 kg. For machine manufacturers and users, it opens up a wide range of new applications which were difficult or not possible to realize with previous equipment such as passive compensation units, force torque sensors and visual systems. The applications range from process automation and quality monitoring to teaching and the controlled handling of objects.

Quantum leap in process automation

With its differentiated kinematics, the tactile all-rounder is able to correct processes with great complexity and tight tolerances, for example in the case of positional deviations between the tool and the work pieces or in complex joining processes with minimal tolerances. Thanks to this tactile sensitivity, tasks that were not automatable can now be performed by robots.

Quicker teaching

In another area, the Smart Flex Effector also reduces the time previously needed for teaching processes. Thanks to the 6D position recording, the robotic control system can read the exact coordinates for gripping and placing points directly. Repeated learning during operation is therefore possible in an automated manner. Robots can also be taught manually – simply by moving them into position by hand.

Sensitive handling of objects

Even during sampling, the Smart Flex Effector can be used to recognize positional deviations and, with the help of the sensor system, to determine the exact position of the object. The robot accurately picks up assembly or handling objects, positions them in a controlled manner and places them reliably or sorts them. Even parts made of glass or other sensitive materials can now be handled safely. In order to ensure maximum productivity, the compensation module can be actively moved into the zero position and electromechanically locked for fast transfer runs.

High connectivity, easy installation

The Smart Flex Effector offers an RS-485 interface as well as an I/O interface for exchanging data. Installation is extremely easy: For a passive compensation function, the Smart Flex Effector is simply screwed to the robot flange and the gripper. The locking function and data transmission are available as soon as the unit is connected to the power supply and the control system.

Related Stories

Aimtron Electronics Enters OEM Engagement with Climate-Tech Firm Aurassure

Aimtron Electronics has partnered with climate-tech company Aurassure to manufacture IoT-enabled environmental monitoring systems supporting real-time, hyperlocal climate and air-quality intelligenc..

Read more

Bharat Forge and Agile Robots sign MoU to Advance AI-Led Industrial Automation

The MoU brings together Bharat Forge’s manufacturing expertise and Germany-based Agile Robots’ AI-led robotics capabilities to accelerate intelligent automation across key civilian industrial se..

Read more

Physical AI Emerges as the Operating System of the Modern Industrial Economy

Physical AI is transforming automation by merging robotics and generative AI to reshape productivity and unlock new industrial applications, shares Dijam Panigrahi, Co-founder and COO, GridRaster In..

Read moreRelated Products

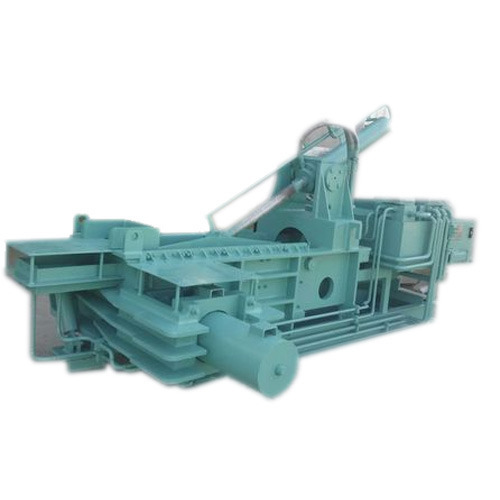

Baling Machine

Mask Hydraulic Machineries provide triple action scrap baling machines. Read more

Manifold Block

Om Shakthi Hydraulics offers a wide range of hydraulic manifold blocks. Read more

Exclusive Hydraulic Fittings

Supreme Engineers is engaged in manufacturing and supplying an exclusive range of hydraulic fittings. Read more